Pervious concrete and preparation method thereof

A technology of permeable concrete and cement, applied in the field of concrete, can solve the problems of low freeze-thaw resistance and easy cracking of permeable concrete, and achieve the effects of improving compression resistance, toughness and high permeability coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

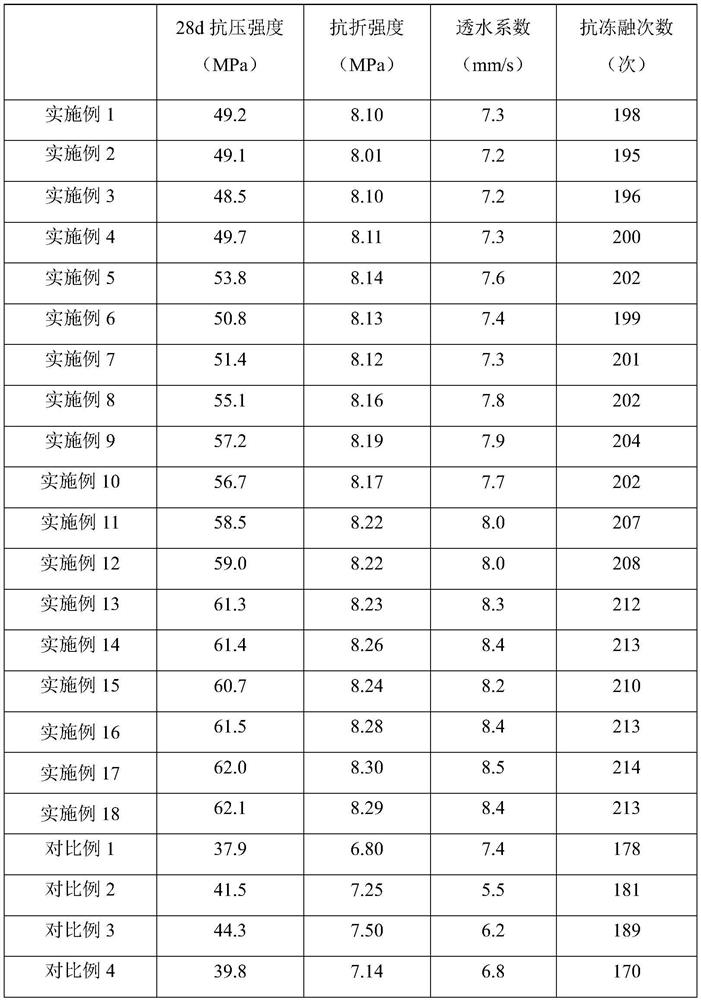

Examples

preparation example 1

[0041] Modified coconut fiber in the application is prepared by the following method:

[0042] Wash 10kg coconut fiber with water;

[0043] Add 500L mass fraction of 5% NaOH solution and 500L mass fraction of 10% H to the washed coconut fiber 2 o 2 In the mixed solution, soak for 5h;

[0044] The soaked coconut fiber is heated up to 100°C, and heat-treated for 1h;

[0045] Wash the heat-treated coconut fiber to neutrality;

[0046] Dry the coconut fiber washed to neutral;

[0047] The dried coconut fiber is cut into coconut fiber with a length of 6mm-10mm to obtain the modified coconut fiber.

preparation example 2

[0049] The modified basalt fiber in this application is prepared by the following method:

[0050] The basalt of the weight shown in Table 1 is pulverized to obtain basalt gravel with a particle size of 5mm-20mm;

[0051] Mix basalt gravel with attapulgite and melt at a high temperature of 1500 to obtain molten liquid;

[0052] Draw the molten liquid, control the length of the basalt fiber to 6mm-10mm, and cool it to obtain the modified basalt fiber.

preparation example 3-5

[0054] The preparation method of the modified basalt fiber of Preparation Example 3-5 is the same as that of Preparation Example 2, the difference is that the dosage of each raw material is different, and the specific details are shown in Table 1.

[0055] The dosage of each raw material of the modified basalt fiber of table 1 preparation example 2-5 (unit: kg)

[0056] raw material Preparation example 2 Preparation example 3 Preparation Example 4 Preparation Example 5 Basalt 10 12 13 14 Attapulgite 2 3 4 5

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com