Concrete pavement brick capable of achieving gap water permeation and self water permeation

A technology of permeable concrete and permeable pavement, applied in the field of building materials, can solve problems such as easy blockage of water permeability, and achieve the effects of convenient and fast paving, large permeable gap, firm and reliable interlocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding and knowledge of the present invention, the present invention will be further described and introduced in conjunction with the accompanying drawings.

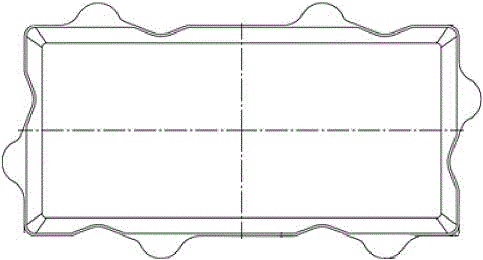

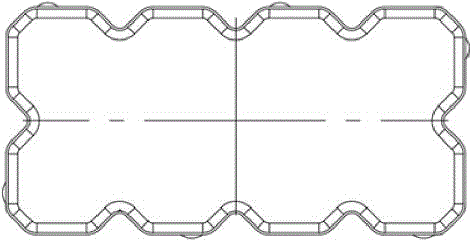

[0019] Aiming at the problem of water permeability failure due to mud, sand and slurry blocking the permeable aperture during paving use of self-permeable concrete pavement bricks, the inventor took advantage of the characteristics of the molding equipment and changed the periphery of the self-permeable concrete pavement brick by redesigning the block type The shape proposes a gap permeable + self-permeable concrete pavement brick with good water permeability and antique imitation sintered brick effect. The pavement brick is a rectangular block with a length of 200mm×100mm. The four corners of the block With rounded corners, the block includes a bearing base layer and an ornamental surface layer set above the base layer, and the four sides of the surface layer and the base layer are set t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com