Method and device for synchronously testing tension, compression and split resilience moduli of pavement material

A technology of elastic modulus and pavement material, which is used in measuring devices, analyzing materials, and testing material strength by applying a stable bending force. It can reflect the real mechanical properties of materials and other problems to achieve the effect of improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

[0038] The simultaneous test method for tensile, compressive and splitting elastic modulus of pavement materials includes the following steps:

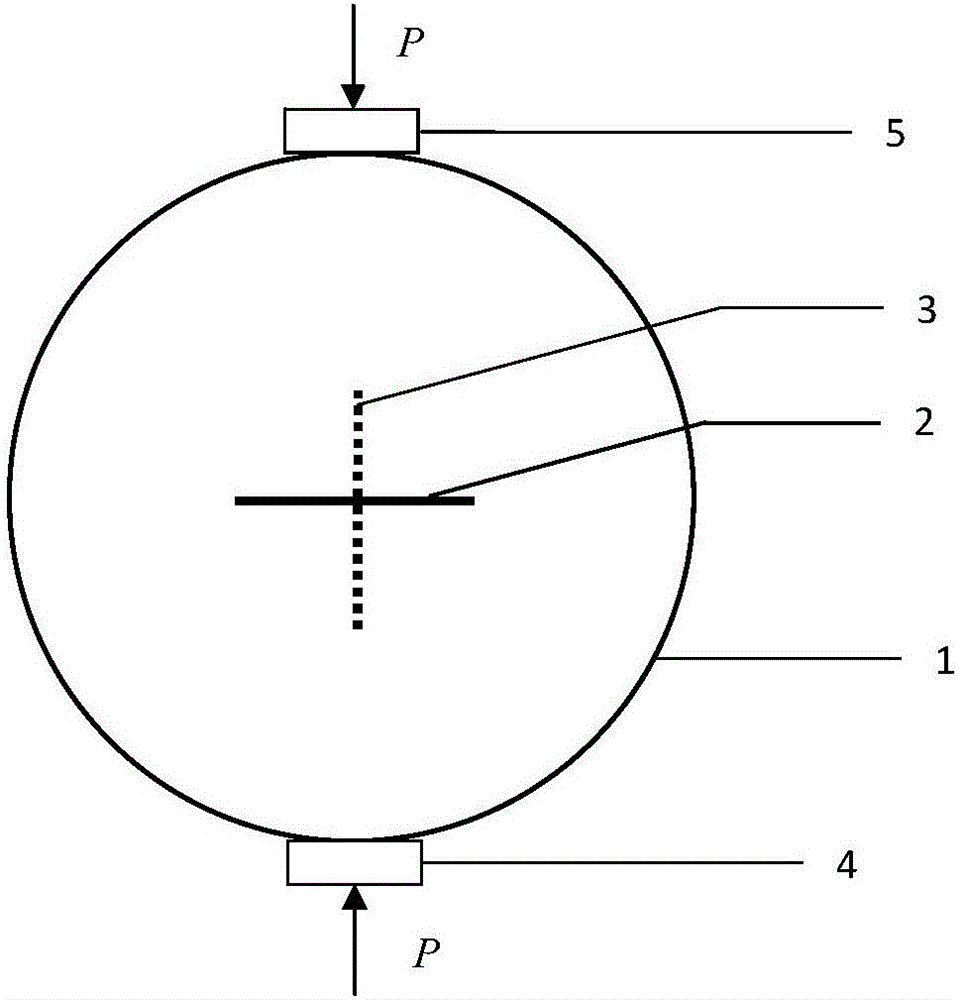

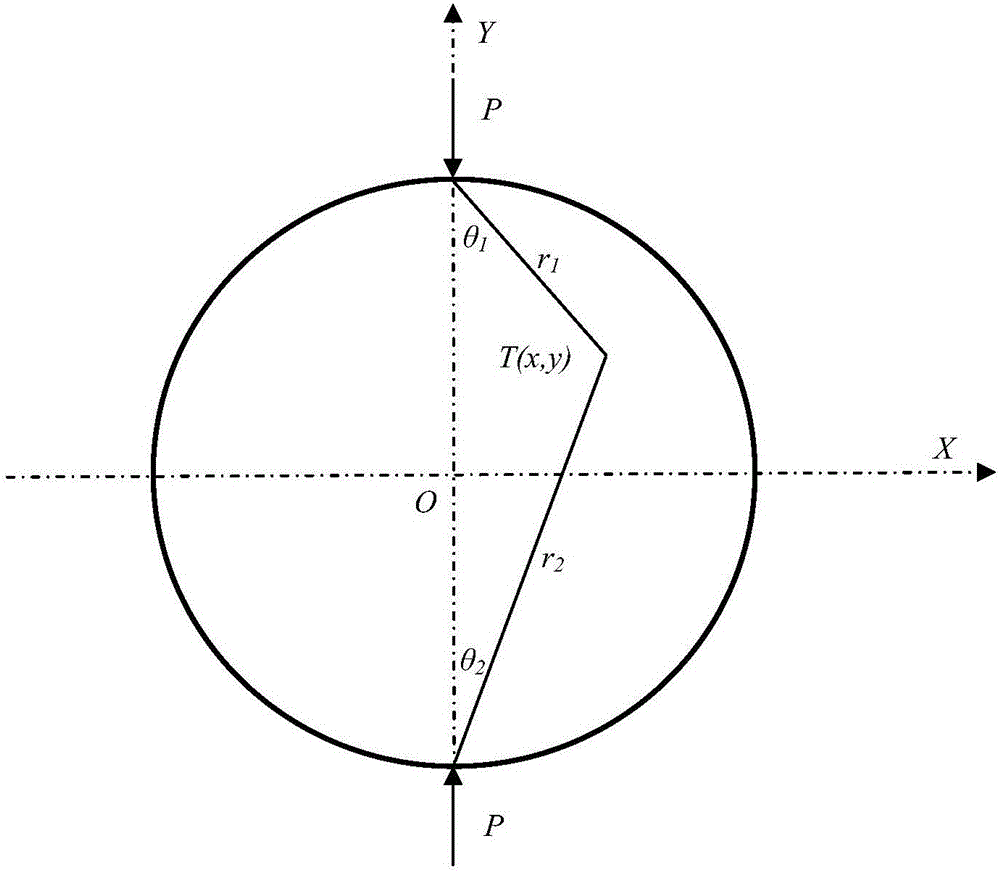

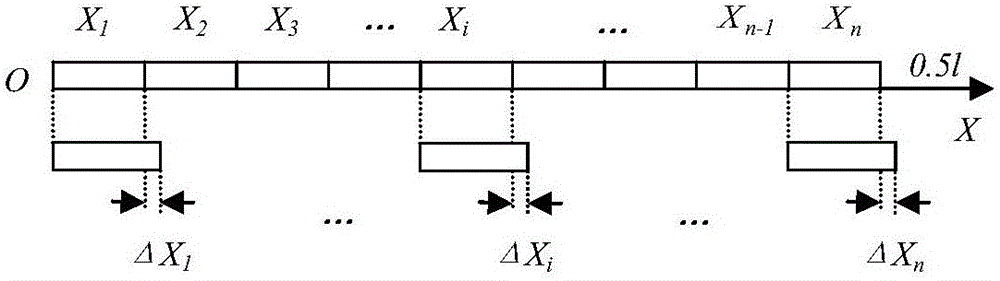

[0039]S1 After the test piece is made, determine the horizontal radial position of the front of the test piece and the vertical radial position of the back, and make marks; Strain gauges in the corresponding direction above, where the midpoint of each strain gauge must coincide with the center of the surface; connect the strain gauges to the strain collector;

[0040] S2 Place the test piece prepared according to step S1 on the splitting test support of the MTS multifunctional material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com