Ultrahigh-strength grouting material based on iron tailing sand and cement and preparation method of grouting material

A technology for iron tailings sand and grouting material, applied in the field of building material engineering, can solve the problems of lagging comprehensive utilization of tailings, and achieve the effects of rough surface and strong cement bonding ability, reducing usage, improving fluidity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

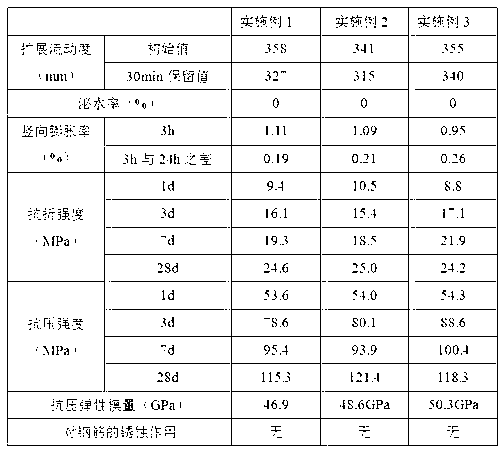

Examples

Embodiment 1

[0039] An ultra-high-strength iron tailings sand cement-based grouting material, according to the weight percentage, its formula is as follows:

[0040] Ordinary 52.5 Portland cement: 36.8%

[0041] 42.5 grade rapid hardening sulfoaluminate cement: 2.5%

[0042] Iron tailings: 49.7%

[0043] Multi-mineral admixture: 8%

[0044] Compensating shrink expansion agent: 2.33%

[0045] Water reducer: 0.4%

[0046] Plastic expansion agent: 0.02%

[0047] Plasticizer: 0.25%

[0048] The fineness modulus of the iron tailings sand used in the mix ratio is 1.7 to 3.0. The particle size and gradation requirements of the iron tailings sand used in the mix ratio are as follows:

[0049] 4.75~2.36mm14%

[0050] 2.36mm~1.18mm35%

[0051] 1.18m~0.3mm31%

[0052] ≤0.3mm20%

[0053] Among them, the fine powder content of iron tailings sand particles with a particle size below 0.075mm is ≤10%, the crushing value is ≤25%, the mud content is ≤1%, and the moisture content is ≤1.0%.

[0054...

Embodiment 2

[0058] An ultra-high-strength iron tailings sand cement-based grouting material, according to the weight percentage, its formula is as follows:

[0059] Ordinary 52.5 Portland cement: 37.2%

[0060] 42.5 rapid hardening sulfoaluminate cement: 2.5%

[0061] Iron tailings: 49.5%

[0062] Multi-mineral admixture: 7.4%

[0063] Compensating shrink expansion agent: 2.5%

[0064] Water reducer: 0.5%

[0065] Plastic expansion agent: 0.02%

[0066] Plasticizer: 0.38%

[0067] The fineness modulus of the iron tailings sand used in the mix ratio is 1.7 to 3.0. The particle size and gradation requirements of the iron tailings sand used in the mix ratio are as follows:

[0068] 2.36mm~1.18mm33%

[0069] 1.18m~0.3mm37%

[0070] 0.3~0.15mm30%

[0071] Crushing value ≤ 25%, mud content ≤ 1%, moisture content ≤ 1.0%.

[0072] The multi-element mineral admixture is composed of silicon powder and S95 grade finely ground slag powder (25% silicon powder, 75% S95 grade finely ground sla...

Embodiment 3

[0076] The ultra-high-strength iron tailings sand cement-based grouting material, according to the weight percentage, its formula is as follows:

[0077] Ordinary 52.5 Portland cement: 32.7%

[0078] Iron tailings: 54%

[0079] Multi-mineral admixture: 10.2%

[0080] Compensating shrink expansion agent: 2.49%

[0081] Water reducing agent: 0.36%

[0082] Plastic expansion agent: 0.02%

[0083] Plasticizer: 0.23%

[0084] The fineness modulus of the iron tailings sand used in the mix ratio is 1.7 to 3.0. The particle size and gradation requirements of the iron tailings sand used in the mix ratio are as follows:

[0085] 2.36mm~1.18mm27%

[0086] 1.18mm~0.3mm53%

[0087] ≤0.3mm20%

[0088] Among them, the fine powder content of iron tailings sand particles with a particle size below 0.075mm is ≤10%, the crushing value is ≤25%, the mud content is ≤1%, and the moisture content is ≤1.0%.

[0089]The water reducer uses FOXtalon101 polycarboxylate powder water reducer produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com