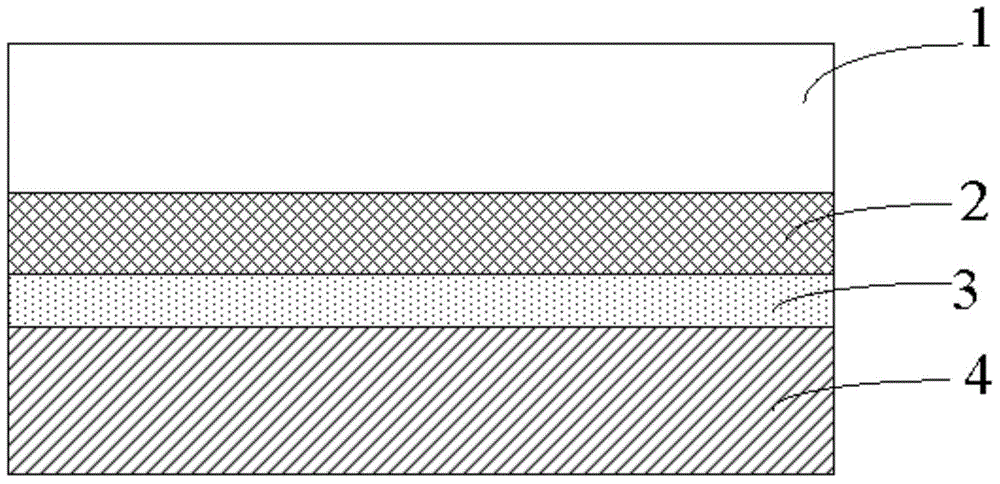

Interface adhesive material, white-to-black overlay structure based on material and construction process of overlay structure

A technology of interfacial bonding, white to black, applied in the direction of asphalt material adhesive, adhesive, adhesive type, etc. Strong adhesion and deformation ability, solving stress concentration, moderate elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

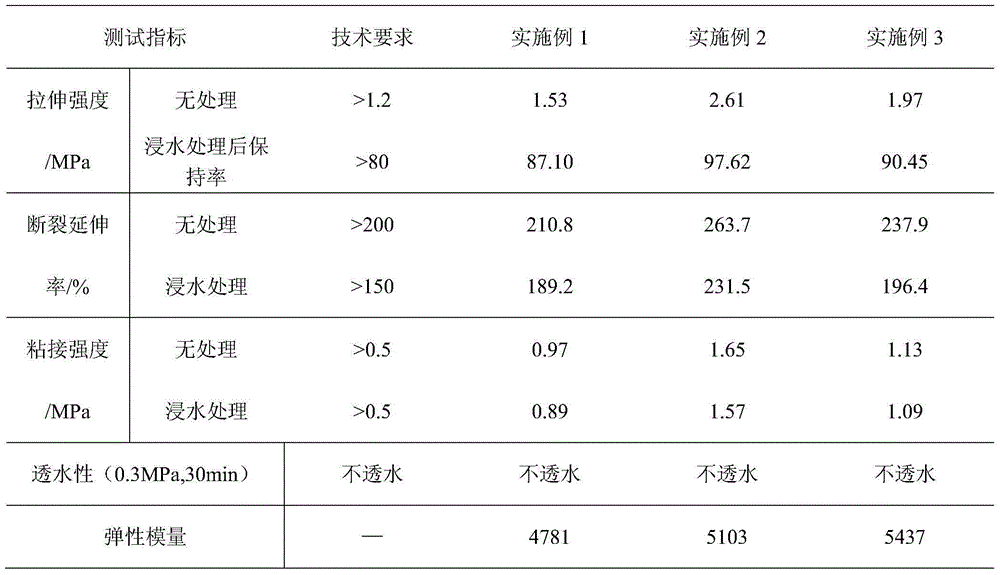

[0042] Check the damage of the road surface of the cement concrete layer 4, repair the diseases of the old road surface, remove the sundries on the road surface, and keep it clean; roughen the road surface of the cement concrete layer 4; mix the interface bonding material on site, and the interface bonding material mix Bottom: 20 parts of dry powder, 100 parts of modified emulsified asphalt, 20 parts of silicone rubber emulsion, 10 parts of polyurethane modified epoxy resin material, wherein the dry powder is made by mixing and stirring the following materials by mass: 100 parts of composite cement, AEA expansion 20 parts of demulsifier, 1.0 part of SP demulsifier, 1.0 part of polysiloxane defoamer; on site, pour dry powder and modified emulsified asphalt into the mixer and stir for 60 seconds, then add polyurethane modified epoxy resin material and silicone rubber emulsion to continue Stir for 90 seconds; pave the well-mixed interface bonding material on the road surface of th...

Embodiment 2

[0044] Check the damage of the road surface of the cement concrete layer 4, repair the diseases of the old road surface, remove the sundries on the road surface, and keep it clean; roughen the road surface of the cement concrete layer 4; mix the interface bonding material on site, and the interface bonding material mix Bottom: 35 parts of dry powder, 100 parts of modified emulsified asphalt, 30 parts of silicone rubber emulsion, 20 parts of polyurethane modified epoxy resin material, wherein the dry powder is mixed and stirred by the following materials in parts by mass: 100 parts of composite cement, HEA expansion 25 parts of demulsifier, 1.3 parts of AR type demulsifier, 1.5 parts of polysiloxane defoamer; on site, pour dry powder and modified emulsified asphalt into the mixer and stir for 60s, then add polyurethane modified epoxy resin material and silicone rubber emulsion to continue Stir for 90 seconds; pave the well-mixed interface bonding material on the road surface of ...

Embodiment 3

[0046] Check the damage of the road surface of the cement concrete layer 4, repair the diseases of the old road surface, remove the sundries on the road surface, and keep it clean; roughen the road surface of the cement concrete layer 4; mix the interface bonding material on site, and the interface bonding material mix Bottom: 50 parts of dry powder, 100 parts of modified emulsified asphalt, 40 parts of silicone rubber emulsion, and 30 parts of polyurethane modified epoxy resin material. Among them, the dry powder is mixed and stirred by the following materials in parts by mass: 100 parts of composite cement, HEA expansion 30 parts of demulsifier, 1.5 parts of AE type demulsifier, 2.0 parts of GP type defoamer; on site, pour dry powder and modified emulsified asphalt into the mixer and stir for 60s, then add polyurethane modified epoxy resin material and silicone rubber emulsion and continue stirring for 90s Get final product; Pave the interfacial bonding material that mixes we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com