A damping rubber buffer

A technology of damping rubber and buffers, which is applied in the direction of elastic shock absorbers, etc., can solve the problems of high machining accuracy of air buffers, difficulty in controlling the amount of oil added, and many parts of oil buffers, and achieve easy and fast processing and assembly. The effect of unrestricted use environment and low processing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

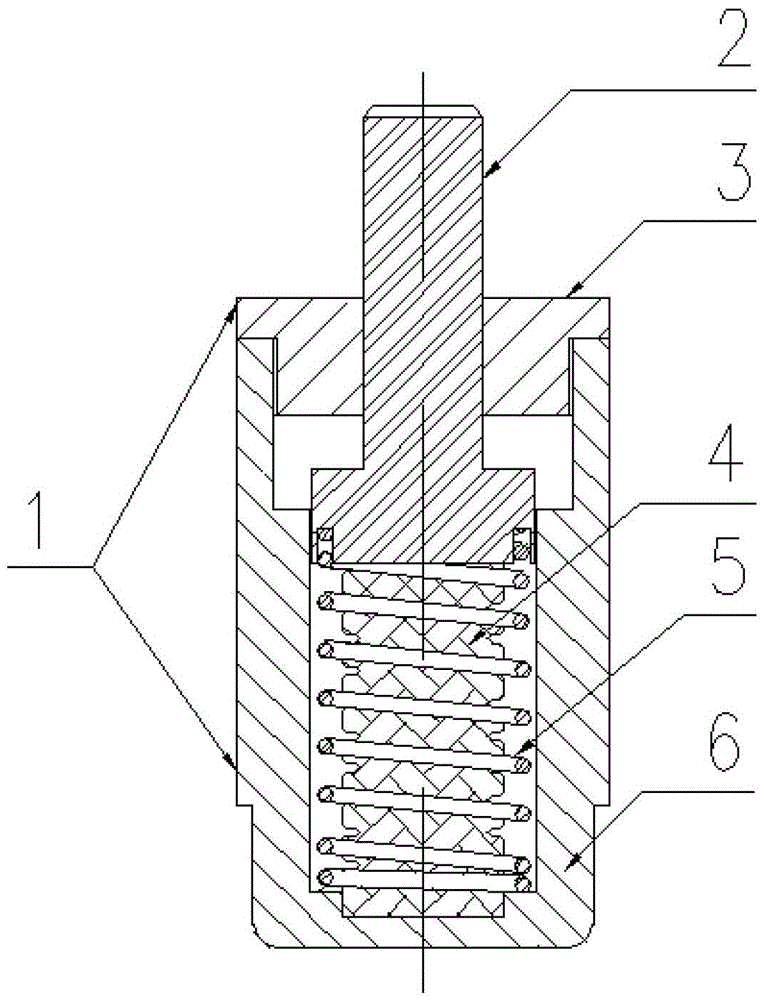

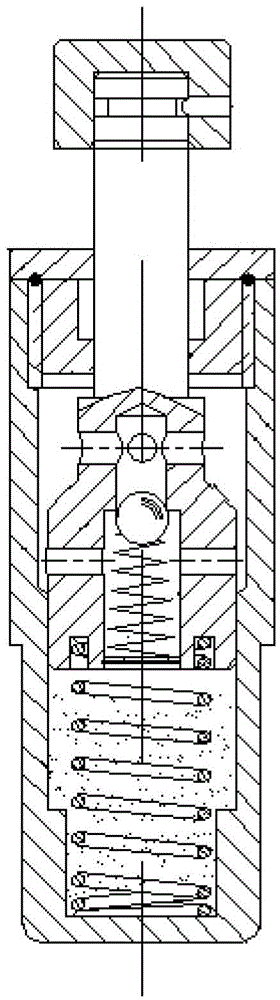

[0017] Such as Figure 1~2 As shown, a damping rubber buffer includes a main body 1, a piston 2, a cylinder cap 3, a damping rubber 4, a compression spring 5 and a cylinder liner 6. Piston 2, damping rubber 4 and stage clip 5 are assembled in the cylinder liner 6, and then the cylinder liner 6 and the cylinder cap 3 are screwed together to form a whole.

[0018] Cylinder cap 3 is made of brass, and the outer thread is tightly fitted with the inner thread of cylinder liner 6.

[0019] The outer diameter of the upper part of the piston 2 is slidingly matched with the inner hole of the cylinder cap 3, and the tolerance clearance is ≥0.2mm; the clearance tolerance between the outer diameter of the lower part of the piston 2 and the inner bottom hole of the cylinder liner 6 is ≥0.5mm;

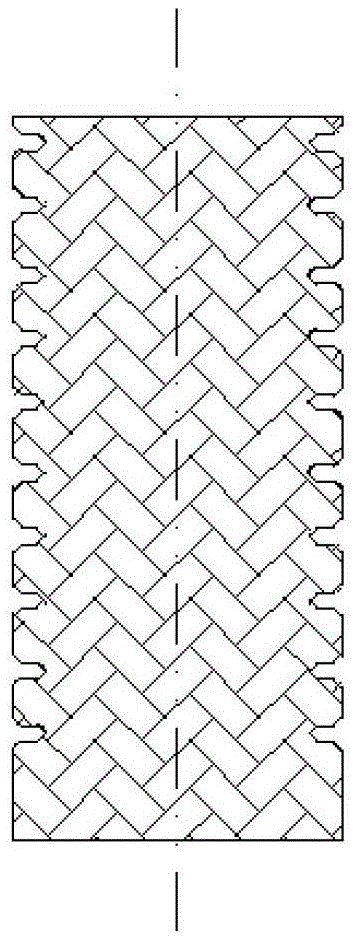

[0020] The damping rubber 4 is a cylindrical body of φ20×44mm, the outer circle is a corrugated structure, the number of corrugations is 10, the wave pitch is 1.8mm, and the depth of the wave valle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com