Composite carbon fiber plane grid rib

A composite carbon fiber, plane technology, applied in the field of reinforcement materials of concrete structures, can solve the problems of poor tensile and bending resistance, easily cracked concrete components, electromagnetic signal interference, etc., and achieves excellent fatigue resistance and elasticity. The effect of moderate modulus and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

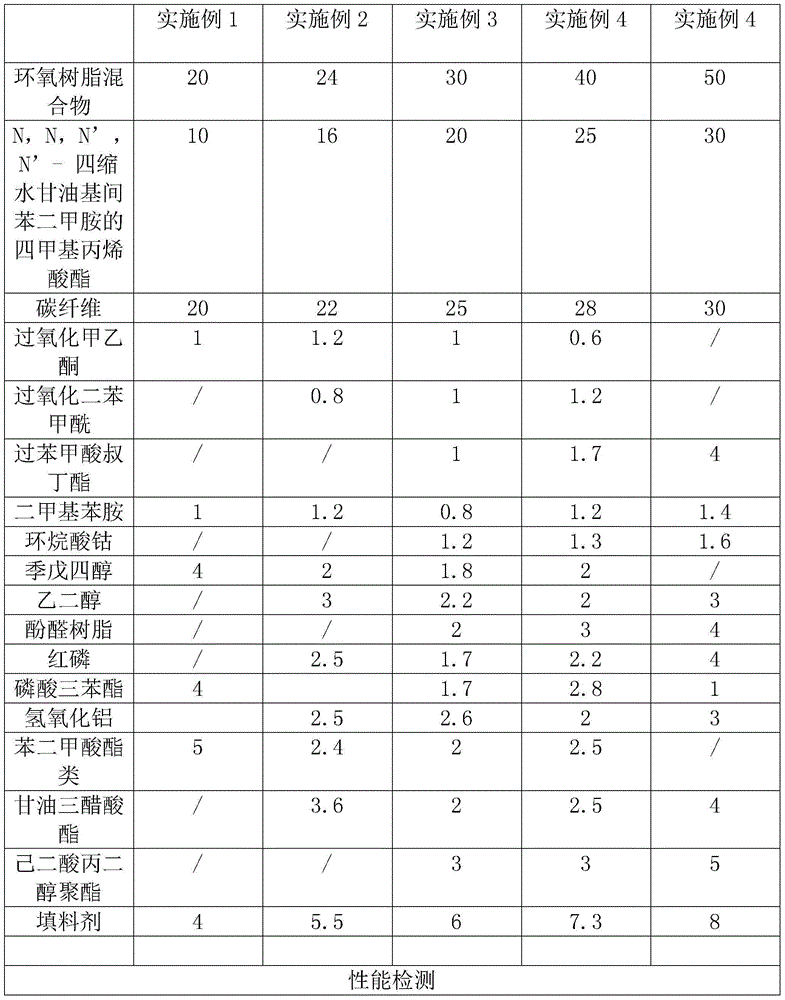

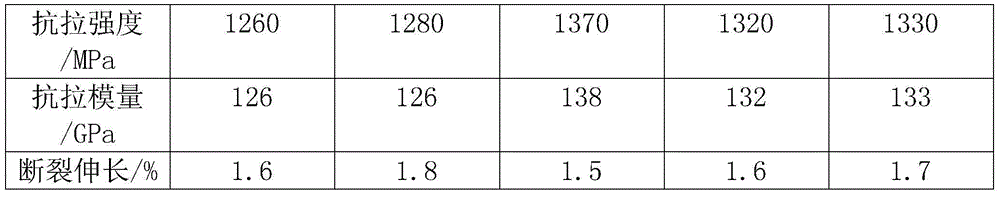

Examples

Embodiment 1

[0020] A composite carbon fiber plane grid bar, the mass parts of the composite carbon fiber plane grid bar consists of: 20 parts of epoxy resin mixture, N, N, N', N'-tetraglycidyl m-xylylenediamine 10 parts of tetramethacrylate, 20 parts of carbon fiber, 1 part of curing agent, 1 part of accelerator, 8 parts of flame retardant, 5 parts of plasticizer, and 4 parts of filler.

[0021] The curing agent is selected from: methyl ethyl ketone peroxide.

[0022] The accelerator is selected for use: dimethylaniline.

[0023] The flame retardant is a mixture of an intumescent flame retardant and a solid flame retardant, and the mass ratio of the intumescent flame retardant to the solid flame retardant is 1:1.

[0024] The intumescent flame retardant is selected from: pentaerythritol.

[0025] The solid flame retardant is selected from red phosphorus.

[0026] The plasticizer is selected from: phthalates.

[0027] Performance testing of finished products.

[0028] The composition ...

Embodiment 3

[0031] Embodiment 3 is the best embodiment of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength retention | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com