Once integral-molded bamboo sleeper and preparation method thereof

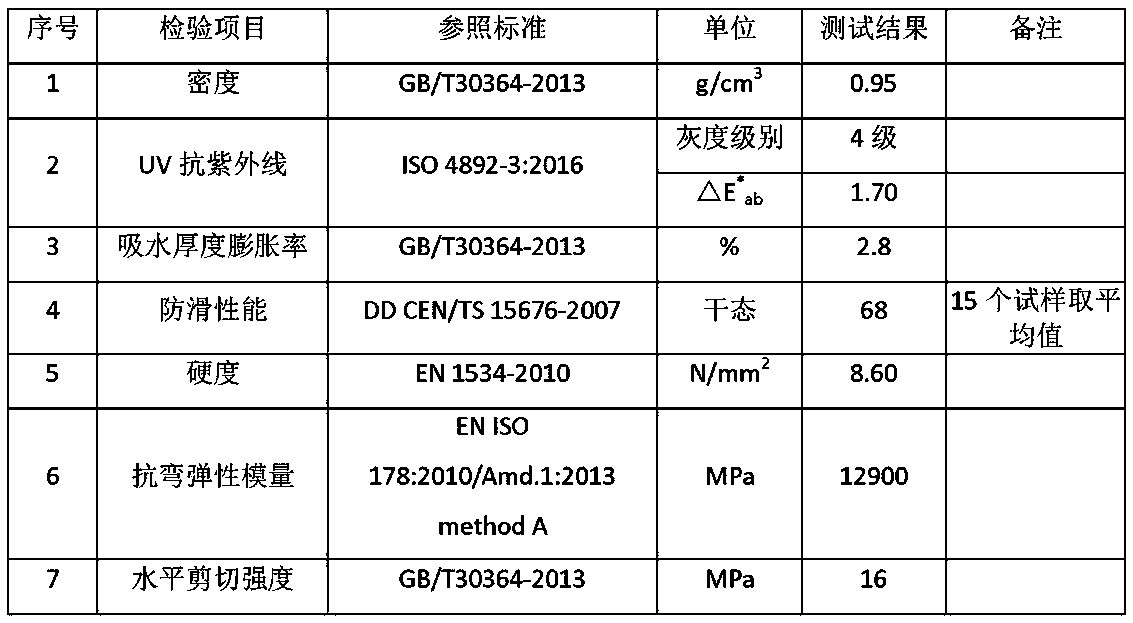

A technology of integral molding and sleepers, which is applied in new materials for urban rail transit and in the field of railways. It can solve the problems of high carbon consumption affecting the environment, poor insulation, and difficulty in recycling, and achieve outstanding economic benefits, good insulation, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

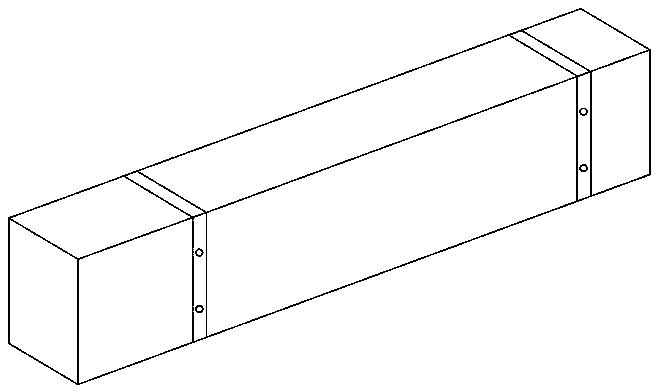

[0041] Embodiment 1 (take a 1800mm long, 200mm wide, 140mm thick bamboo sleeper as an example)

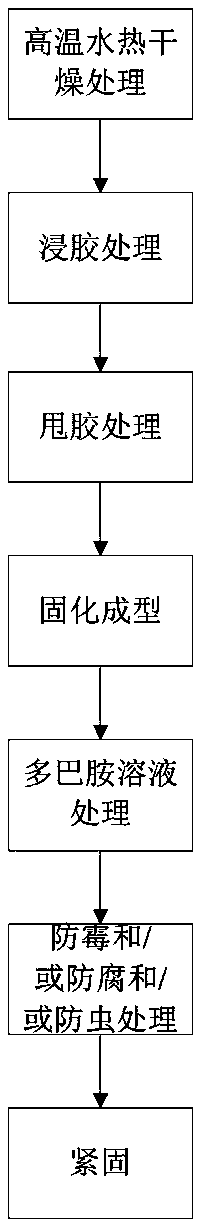

[0042] Such as figure 1 As shown, the preparation method of the integrally formed bamboo sleeper of the present embodiment specifically comprises the following steps:

[0043] (1) Select 4-year-old Moso bamboo, cut it off, and each section is 1900mm±10mm to obtain round bamboo sections.

[0044] (2) Break the bamboo rounds into bamboo units, remove 100% of the bamboo green and bamboo yellow, cook in ammonia water with a pH value of 8.5 for 30 minutes, wash with water, and then mechanically grind them into filamentous bamboo units.

[0045] (3) The filamentary bamboo unit is dried in superheated steam with a dry bulb temperature of 150°C and a superheated degree of 30°C to a moisture content of about 13%, to obtain a dried and modified filamentary bamboo unit. High-temperature hydrothermal modification treatment can kill microorganisms and insect pests, and can also decompose star...

Embodiment 2

[0060] This embodiment is roughly the same as Embodiment 1, except that the high-frequency assisted high-temperature hot-pressing process is replaced by bi-directional pressure-bi-directional heating forming technology, and the specific steps are as follows:

[0061] Assemble the blanks to obtain a slab, put the slab on the backing plate, apply pressure and heat treatment to the upper and lower sides of the slab for 70 minutes, and solidify the slab to obtain a bamboo sleeper blank, wherein the center of the slab is The pressure is 20MPa and the temperature is 130°C.

Embodiment 3

[0063] This embodiment is roughly the same as Embodiment 1, except that the high-frequency assisted high-temperature hot-pressing process is replaced by room-temperature cold-press mold clamping-high-temperature curing molding technology, and the specific steps are as follows:

[0064] Place the billet in the cold pressing mold, and use the cold press to compress the billet in the mold. After the compression reaches 140mm, lock the mold and the billet, and then send the mold loaded with the billet into a high-temperature drying kiln at a temperature of 130°C In the middle, it lasts for 5 hours to fully solidify the slab. After the curing is completed, let the mold and the slab gradually cool in the indoor environment. When the temperature of the slab is 40°C higher than the indoor temperature, remove the mold, and the bamboo sleeper slab is solidified and formed. Obtain bamboo sleeper blanks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com