Method for preparing nano hydroxyapatite/polymer composite bone substitution material

A technology of nano-hydroxyapatite and composite materials, applied in medical science, prosthesis, etc., to achieve high tensile and bending strength, high dispersion, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) 5g polyamide (PA66) is dissolved in 20ml organic solvent formic acid;

[0036] (2) Take n-HA sol according to the design ratio (weight ratio 1:1), stir and blend with PA66 solution at 90°C for 3 hours, and make n-HA particles evenly distributed in PA66 under the action of stirring force field and composite;

[0037] (3) Centrifuge the prepared blend solution at a speed of not less than 10000r / min for more than 10min, and separate the sediment from the supernatant.

[0038](4) After the sediment was washed 6 times with deionized water, it was washed 2-3 times with ethanol. Dry the product at 65°C for 24 hours;

[0039] (5) Press and dry the composite powder at a temperature of 260° C. with a conventional thermocompression molding machine to obtain n-HA / PA66 composite material.

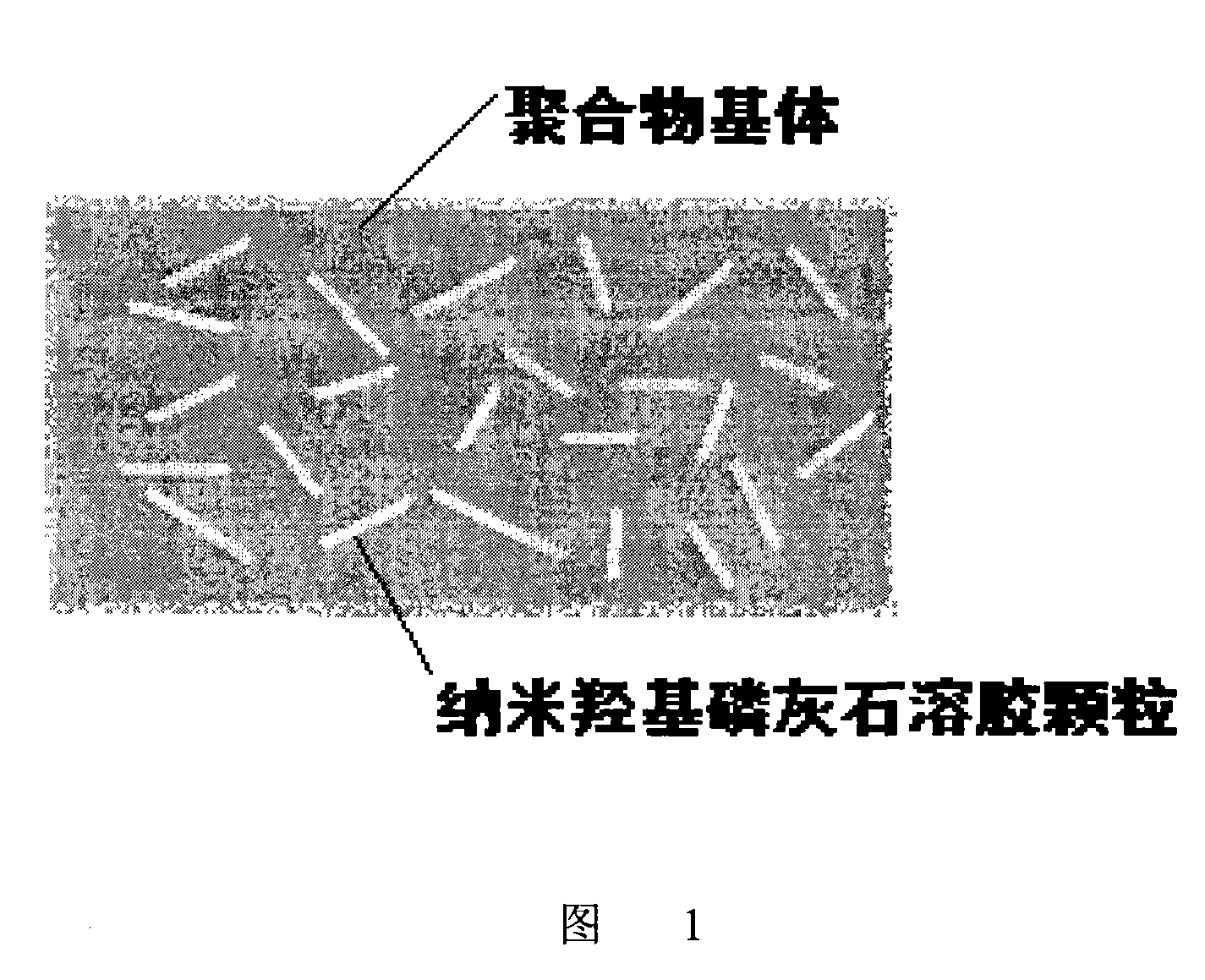

[0040] The experimental results show that the components of the n-HA and PA66 phases do not change after the above method is blended (X-ray diffraction results); the prepared n-HA / PA66 com...

Embodiment 2

[0042] (1) Dissolve 5g of polyurethane (PU) in 20ml of organic solvent acetic acid;

[0043] (2) Take n-HA sol according to the design ratio (weight ratio 1:1), stir and blend with PU solution at 90°C for 3 hours, and make liquid crystal n-HA particles uniform in PU under the action of stirring force field distribute and combine;

[0044] (3) Centrifuge the prepared blend solution at a speed of not less than 10000r / min for more than 10min, and separate the sediment from the supernatant.

[0045] (4) After the sediment was washed 6 times with deionized water, it was washed 2-3 times with ethanol. Dry the product at 65°C for 24 hours;

[0046] (5) The n-HA / PU composite material is obtained by hot pressing at 280° C. using a hot pressing machine.

[0047] The n-HA / PU biological composite material prepared above, its hydroxyapatite is the diameter 10-15nm long 100-200nm rod-shaped particle, content is 20-60wt%, is evenly distributed in PU matrix, makes the polymer mechanical pr...

Embodiment 3

[0049] (1) According to the chemical reaction equation: 10Ca(NO 3 ) 2 +6(NH 4 ) 3 PO 4 +2NH 3 ·H 2 O→Ca 10 (PO 4 ) 6 (OH) 2 +20NH 4 NO 3 , in order to prepare 2g nano-hydroxyapatite (n-HA), weigh (NH) according to the ratio of 1:2 4 PO 3 and Ca(NO) 3 , were dissolved in distilled water, the concentrations of the aqueous solutions were 0.05g / ml and 0.025g / ml. Gelatin was also dissolved in distilled water to make a 0.2 g / ml solution.

[0050] (2) Add 200ml glycerin, gelatin solution and Ca(NO) successively in the three-necked flask 2 solution, wherein the volume ratio of the three solutions is 1:1:2, blending and heating to 85°C, and adding (NH) dropwise to the above mixed solution at a speed of 40ml / h 4 PO 3 The solution is about 50ml, and at the same time, use commercially available ammonia (NH 3 ·H 2 O) adjust the pH value of the blend to 10. After all the dropwise addition was completed, the solution continued to react for 20 min.

[0051] (3) Then raise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com