Hydrophilic film and preparation method thereof

A hydrophilic film and hydrophilic technology, applied in the direction of coating, etc., can solve the problems of unsatisfactory water absorption and water retention rate of the hydrophilic film, difficult to obtain comprehensive performance, unfavorable fit, etc., to achieve good water absorption, high Good water retention and fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

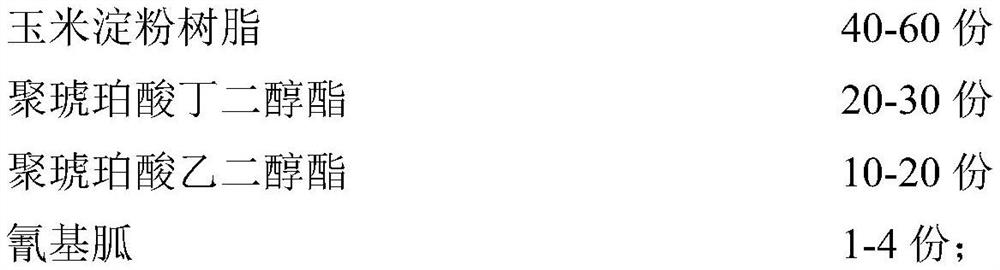

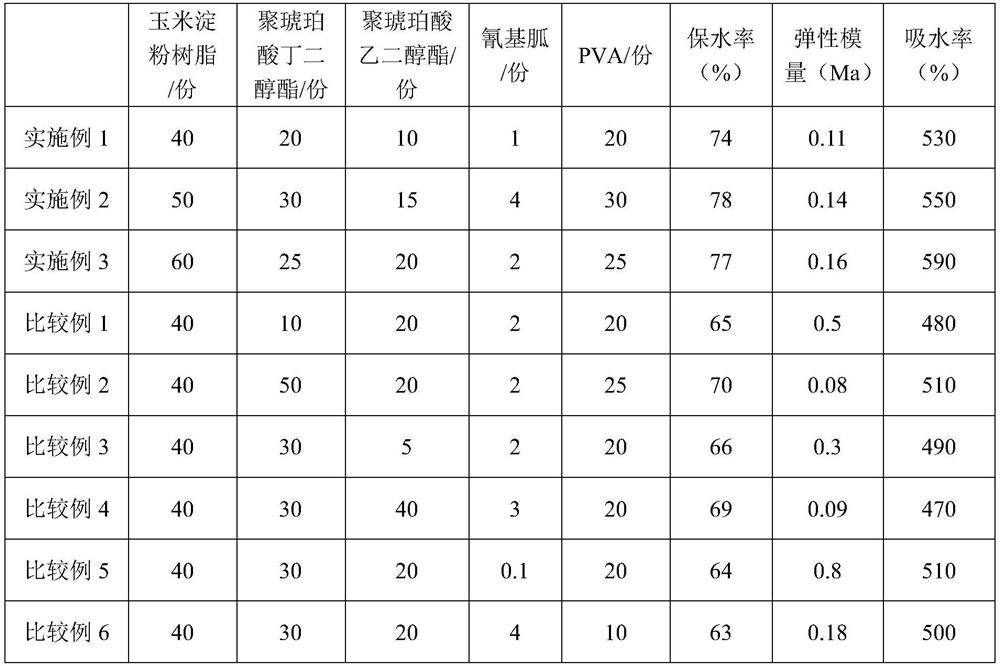

[0026] The preparation method of the hydrophilic fiber membrane: mix 40 parts of cornstarch resin, 20 parts of polybutylene succinate, 10 parts of polyethylene succinate, and 1 part of cyanoguanidine, and then melt extrude at 200 ° C. The blown film is solidified and formed to obtain the desired hydrophilic fiber film.

[0027] Preparation method of hydrophilic coating: Add 20 parts of PVA to 30 parts of deionized water, then stir and dissolve completely at 70°C, cool to room temperature, add the solution to SK-1170, and emulsify for half an hour to obtain the required hydrophilic coating coating.

[0028] The preparation method of the hydrophilic membrane: uniformly coat the hydrophilic coating prepared above on the hydrophilic fiber membrane with a coating thickness of 1-10 μm, and dry it in a 60° C. drying oven for 3 minutes to obtain the desired hydrophilic membrane.

Embodiment 2

[0030] The preparation method of the hydrophilic fiber membrane: mix 50 parts of cornstarch resin, 30 parts of polybutylene succinate, 15 parts of polyethylene succinate, and 4 parts of cyanoguanidine, and then melt extrude at 200 ° C. The blown film is solidified and formed to obtain the desired hydrophilic fiber film.

[0031] Preparation method of hydrophilic coating: add 30 parts of PVA to 30 parts of deionized water, then stir and dissolve completely at 70°C, cool to room temperature, add the solution to SK-1170, and emulsify for half an hour to obtain the desired hydrophilic coating. water paint.

[0032] The preparation method of the hydrophilic membrane: uniformly coat the hydrophilic coating prepared above on the hydrophilic fiber membrane with a coating thickness of 1-10 μm, and dry it in a 60° C. drying oven for 3 minutes to obtain the desired hydrophilic membrane.

Embodiment 3

[0034] The preparation method of the hydrophilic fiber membrane: mix 60 parts of cornstarch resin, 25 parts of polybutylene succinate, 20 parts of polyethylene succinate, and 2 parts of cyanoguanidine, and then melt extrude at 200 ° C. The blown film is solidified and formed to obtain the desired hydrophilic fiber film.

[0035] Preparation method of hydrophilic coating: add 25 parts of PVA to 30 parts of deionized water, then stir and dissolve completely at 70°C, cool to room temperature, add the solution to SK-1170, and emulsify for half an hour to obtain the desired hydrophilic coating. water paint.

[0036] The preparation method of the hydrophilic membrane: uniformly coat the hydrophilic coating prepared above on the hydrophilic fiber membrane with a coating thickness of 1-10 μm, and dry it in a 60° C. drying oven for 3 minutes to obtain the desired hydrophilic membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com