High-strength and high-toughness epoxy resin concrete for bridge expansion joint transition zone and preparation method thereof

A technology of tough epoxy resin and epoxy resin, which is applied in the field of high-strength and high-toughness epoxy resin concrete and its preparation in the transition zone of bridge expansion joints, can solve the problems of short concrete life, long open traffic time, etc., and achieve impact resistance Good, the opening time is short, and the effect of improving impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

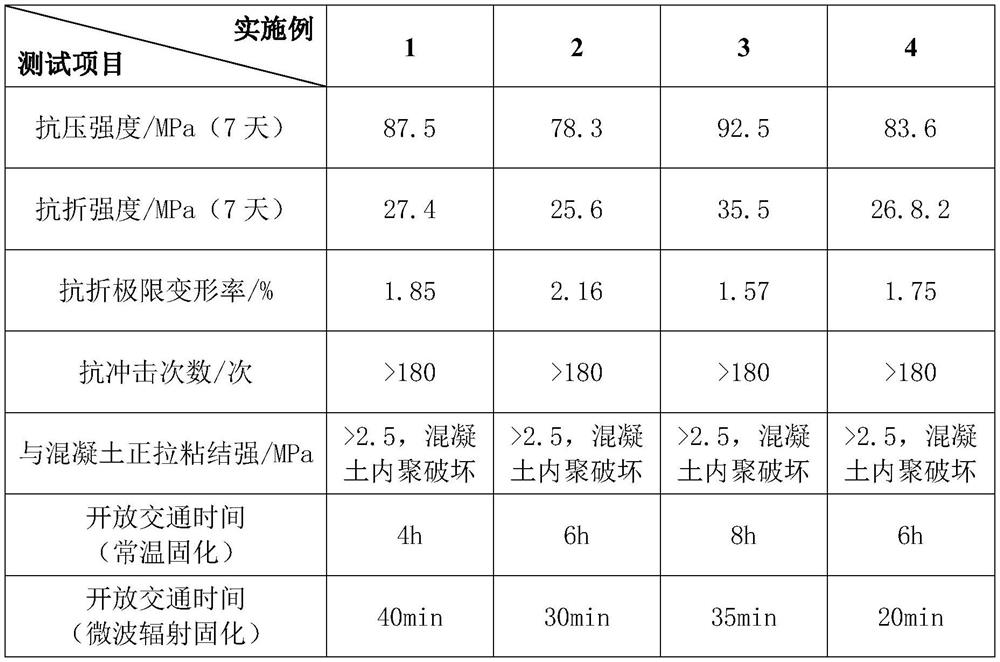

Examples

Embodiment 1

[0033] The high-strength and high-toughness epoxy resin concrete for the bridge expansion joint transition area is composed of three components A, B, and C, and its mass ratio is A component: B component: C component = 100:25:500; The formula in parts by mass is: 35 parts of nano-rubber modified epoxy resin, 60 parts of liquid bisphenol A epoxy resin, 0 part of epoxy reactive diluent, 0.10 part of defoamer, 0.10 part of dispersant; B component The formula in parts by mass is: 100 parts of epoxy curing agent, 0 part of curing accelerator, 0.5 parts of coupling agent, 0.01 part of pigment; the formula of component C in parts by mass is: 100 parts of sand, 50 parts of quartz powder ﹑10 parts of fly ash ﹑5 parts of waste rubber powder ﹑5 parts of magnet powder ﹑10 parts of chopped fiber.

[0034] The nano-rubber modified epoxy resin in the A component is the HH-0802 product produced by Zhuzhou Tongxin Industrial Development Co., Ltd.; the liquid bisphenol A epoxy resin is E-44; th...

Embodiment 2

[0043] The high-strength and high-toughness epoxy resin concrete for the bridge expansion joint transition area is composed of three components A, B, and C, and the mass ratio is A component: B component: C component = 100:40:700; The formula in parts by mass is: 45 parts of nano-rubber modified epoxy resin, 50 parts of liquid bisphenol A epoxy resin, 3 parts of epoxy reactive diluent, 0.20 parts of defoamer, 0.20 parts of dispersant; B component The formula in parts by mass is: 100 parts of epoxy curing agent, 3 parts of curing accelerator, 1 part of coupling agent, 0.03 parts of pigment; the formula of component C in parts by mass is: 100 parts of sand, 80 parts of quartz powder ﹑12 parts of fly ash ﹑10 parts of waste rubber powder ﹑10 parts of magnet powder ﹑15 parts of chopped fiber.

[0044] The nano-rubber modified epoxy resin in the A component is the HH-0801 product produced by Zhuzhou Tongxin Industrial Development Co., Ltd.; the liquid bisphenol A epoxy resin is E-51...

Embodiment 3

[0053] The high-strength and high-toughness epoxy resin concrete for the bridge expansion joint transition zone is composed of three components A, B, and C, and its mass ratio is A component: B component: C component = 100:50:800; The formula in parts by mass is: 50 parts of nano-rubber modified epoxy resin, 45 parts of liquid bisphenol A epoxy resin, 5 parts of epoxy reactive diluent, 0.30 part of defoamer, 0.30 part of dispersant; B component The formula in parts by mass is: 100 parts of epoxy curing agent, 5 parts of curing accelerator, 2 parts of coupling agent, 0.05 parts of pigment; the formula of component C in parts by mass is: 100 parts of sand, 100 parts of quartz powder ﹑15 parts of fly ash, 15 parts of waste rubber powder, 15 parts of magnet powder, 20 parts of chopped fiber.

[0054] The nano-rubber modified epoxy resin in the A component is the HH-0803 product produced by Zhuzhou Tongxin Industrial Development Co., Ltd.; the liquid bisphenol A epoxy resin is a mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com