Patents

Literature

34results about How to "Short opening hours for traffic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Concrete pavement material for heavy traffic roads and preparation method thereof

ActiveCN104193221AElastic modulus controllableHigh modulus of elasticitySolid waste managementMass ratioWaste rubber

The invention relates to a concrete pavement material for heavy traffic roads and a preparation method thereof. The material is composed of a component A, a component B and a component C in a mass ratio of 1:(0.2-0.6):(4-8). The component A comprises the following components in parts by mass: 40-80 parts of epoxy resin, 0-20 parts of epoxy reactive diluent, 10-50 parts of elastic modifier, 0.2 part of defoaming agent and 0.2 part of dispersing agent. The component B comprises the following components in parts by mass: 100 parts of curing agent, 0-10 parts of curing accelerator and 1 part of coupling agent. The component C comprises the following components in parts by volume: 100 parts of fine stone, 30-300 parts of fine sand, 130-800 parts of waste rubber particle, 50-100 parts of waste rubber powder and 10-20 parts of crystal whisker. Compared with the prior art, the concrete pavement material for heavy traffic roads has the advantages of high strength, favorable durability, favorable roadability, energy saving, environment friendliness and the like, and is convenient for construction.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

Cold mix epoxy resin material for quickly repairing epoxy asphalt pavement pits as well as preparation method and application thereof

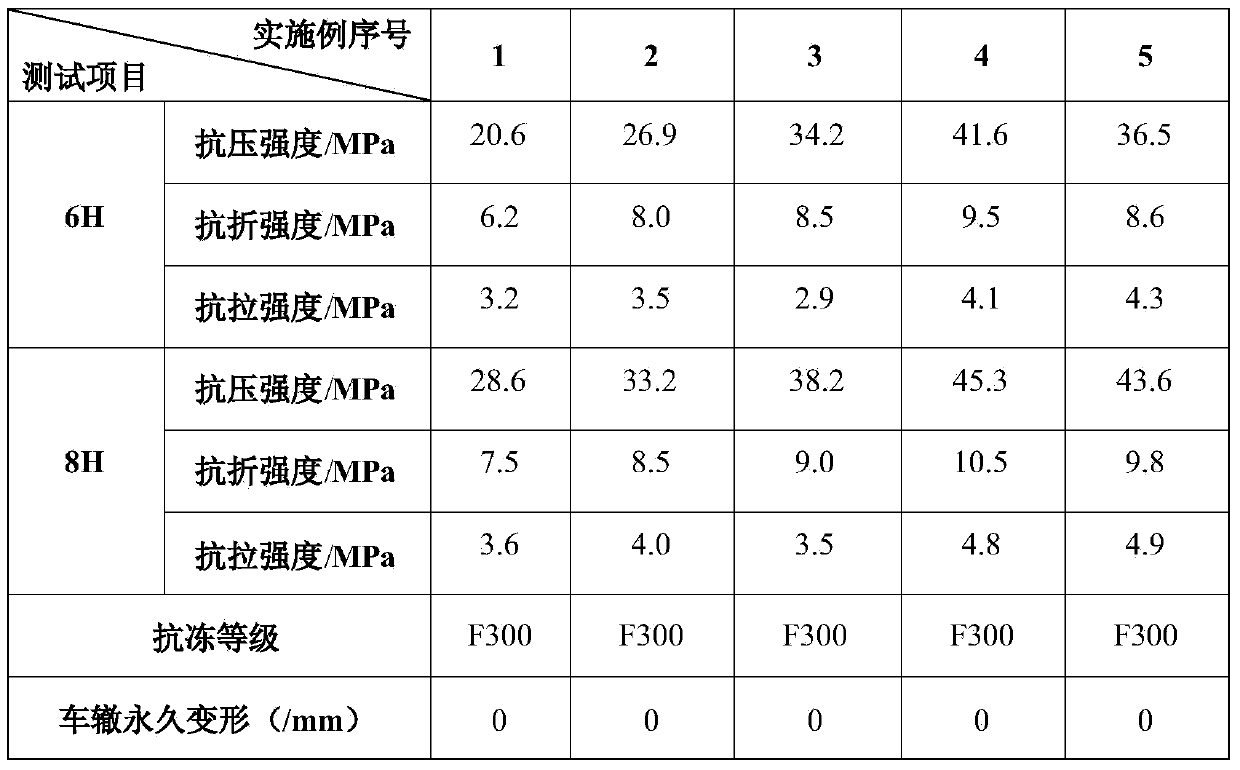

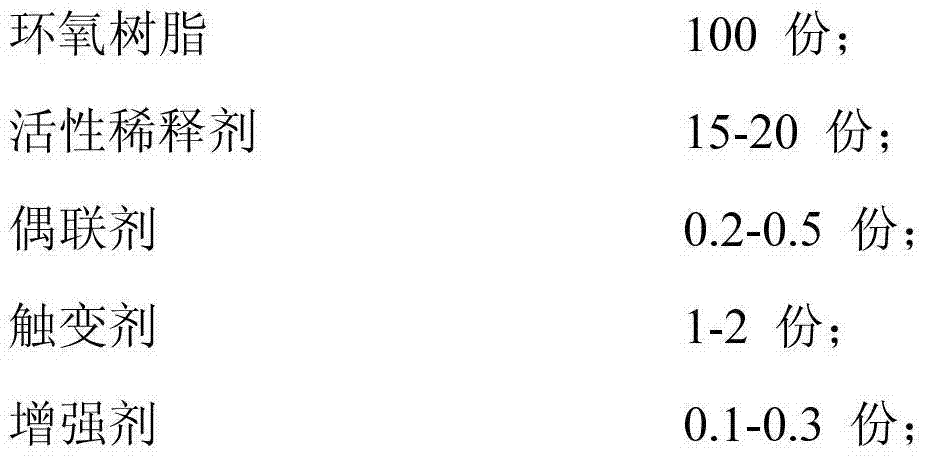

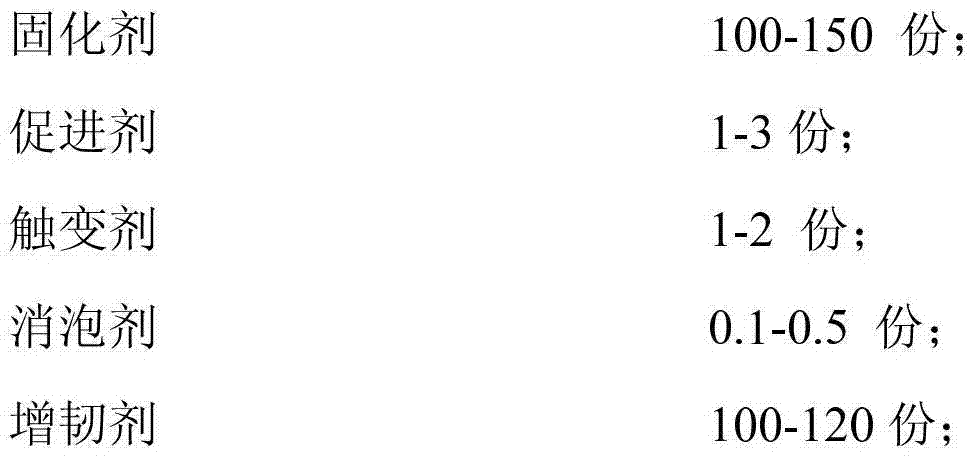

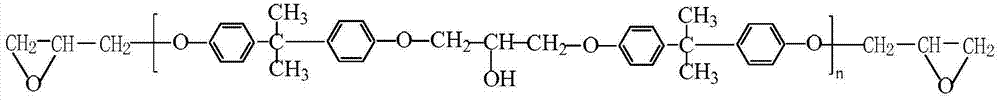

The invention discloses a cold mix epoxy resin material for quickly repairing epoxy asphalt pavement pits. The cold mix epoxy resin material comprises a component A and a component B, wherein the component A mainly comprises epoxy resin, an active diluent, a coupling agent, a thixotropic agent and a reinforcing agent, and the component B mainly comprises a curing agent, an accelerant, a thixotropic agent, a defoaming agent and a toughening agent. The mass ratio of the component A to the component B is 100: (200 to 100): 260, a mixture of components A and B is mixed with aggregate to obtain a cold mix epoxy resin mixture, and the mass ratio of the sum of the A component and the B component to the aggregate is 16:84 to 19:81. The cold mix epoxy resin material for quickly repairing epoxy asphalt pavement pits disclosed by the invention has the advantages of high bonding strength, good toughness, good waterproofness, normal temperature mixing, simple construction process, short open traffic time, energy conservation, environmental protection, etc. The cold mix epoxy resin material disclosed by the invention is mainly suitable for quickly repairing epoxy asphalt pavement pits and suitable for quickly repairing such pavements as high grade highways, tunnels, airport runways, cement concrete bridge decks, etc. The invention discloses a preparation method of the cold mix epoxy resin material.

Owner:NANJING UNIV

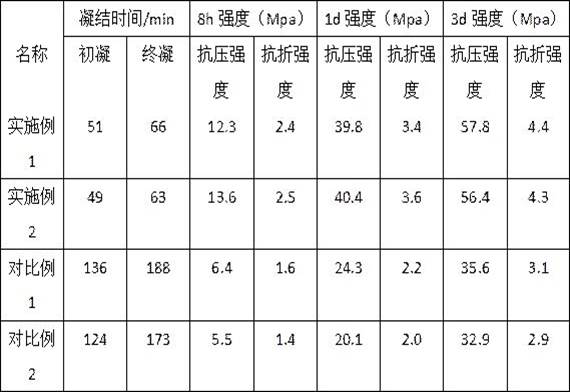

Method for quickly repairing concrete road surface

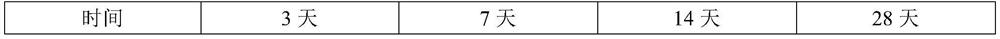

ActiveCN101817663AShort opening hours for trafficIn situ pavingsSolid waste managementSlagPortland cement

The invention discloses a method for quickly repairing a concrete road surface. Each cubic meter of road surface repairing materials adopted by the method comprise the following components by weight: 333 to 387kg of metakaolin, 138kg of slag, 28 to 82kg of ordinary Portland cement, 415kg of water glass, 708kg of medium sand and 1,505kg of stones (5-20mm), wherein the modulus of the water glass is1.4; the water cement ratio of the formula is 0.37 to 0.39; the water content comprises the contained water of the water glass and the externally added water; and the amount of the externally added water is co-determined by the water cement ratio and the contained water of the water glass. Compared with the ordinary cement concrete repairing method, the method of the invention can greatly shortenthe open traffic time; the road repaired by the method of the invention can be used only 8 to 10 hours later at most; and the durability of the repairing materials and the bonding property of the newand old concrete are far superior to those of the ordinary concrete repairing material.

Owner:CHONGQING UNIV

Perfusion material for bridge expansion joint transition region, and preparation method and construction process thereof

Belonging to the technical field of chemical building materials, the invention discloses a perfusion material for a bridge expansion joint transition region, and a preparation method and construction process thereof. The perfusion material consists of three components, A, B and C. The component A consists of epoxy resin, an epoxy active diluent, a superfine waste rubber powder, an antifoaming agent and a dispersing agent; the component B consists of a curing agent, a curing agent promoter and a coupling agent; and the component C consists of waste rubber particles, a waste rubber powder and whiskers. The component A and component B are mixed and stirred evenly, and then the component C is added and mixed evenly to obtain the perfusion material. In construction, first a contact surface of a reserved groove of the bridge expansion joint and the perfusion material is coated with a layer of adhesive, and then the perfusion material is poured into reserved groove of the bridge expansion joint. The perfusion material prepared by the invention has high bonding strength, good construction performance, short time before traffic usage, good wear resistance, shock absorption and noise reduction performances, high mechanical properties, excellent impact resistance and durability, and substantial environmental benefits.

Owner:山西省交通科技研发有限公司

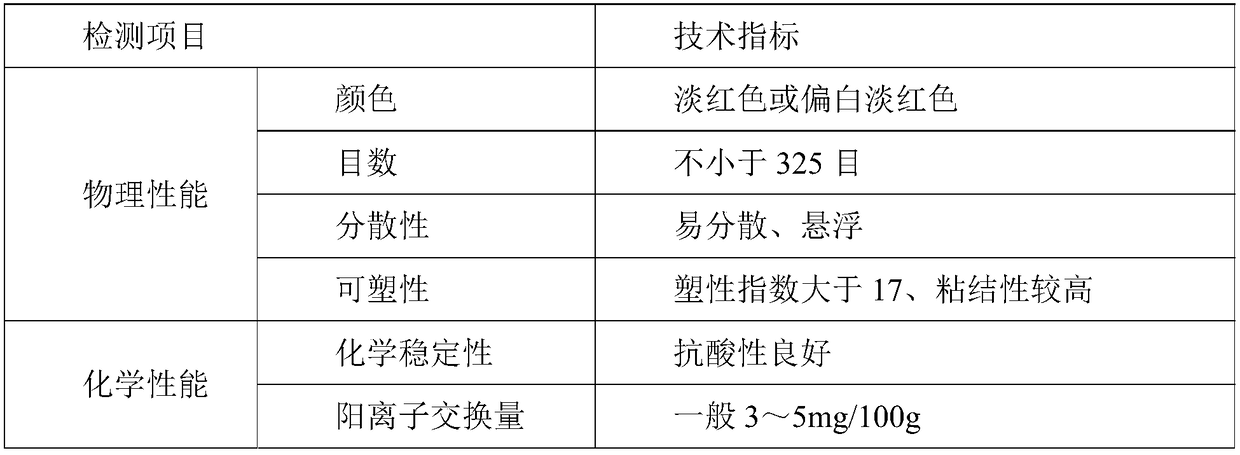

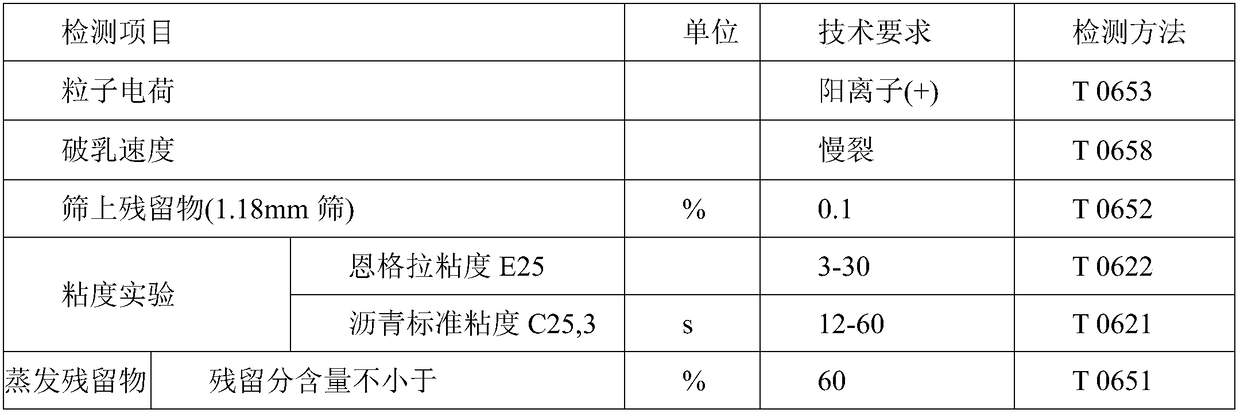

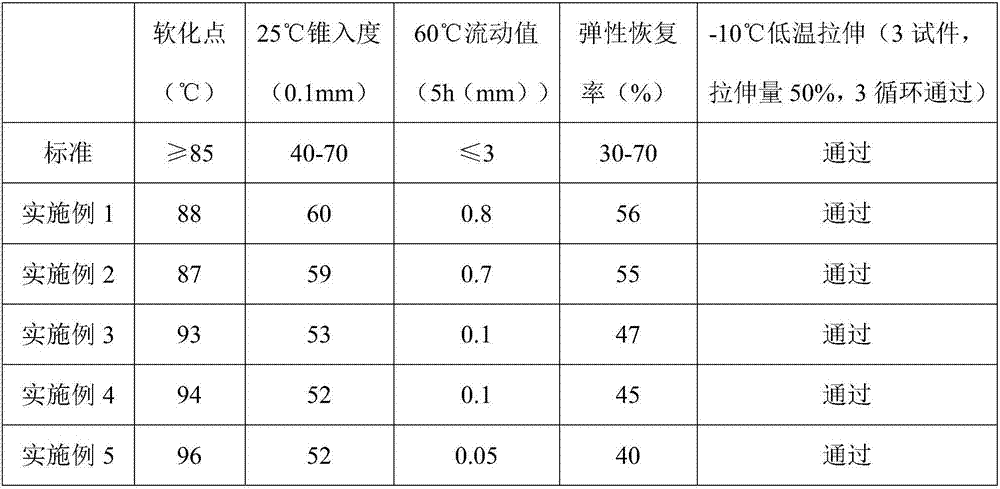

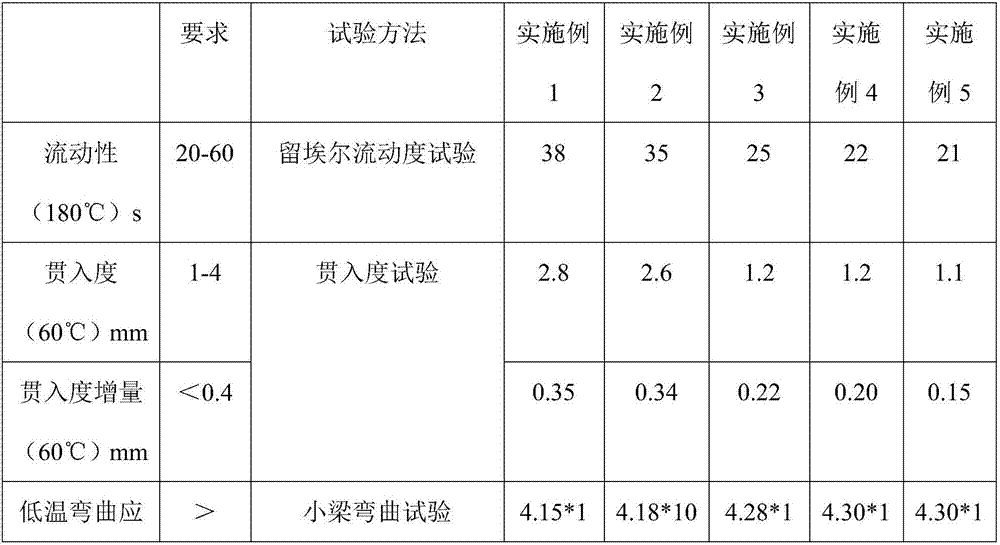

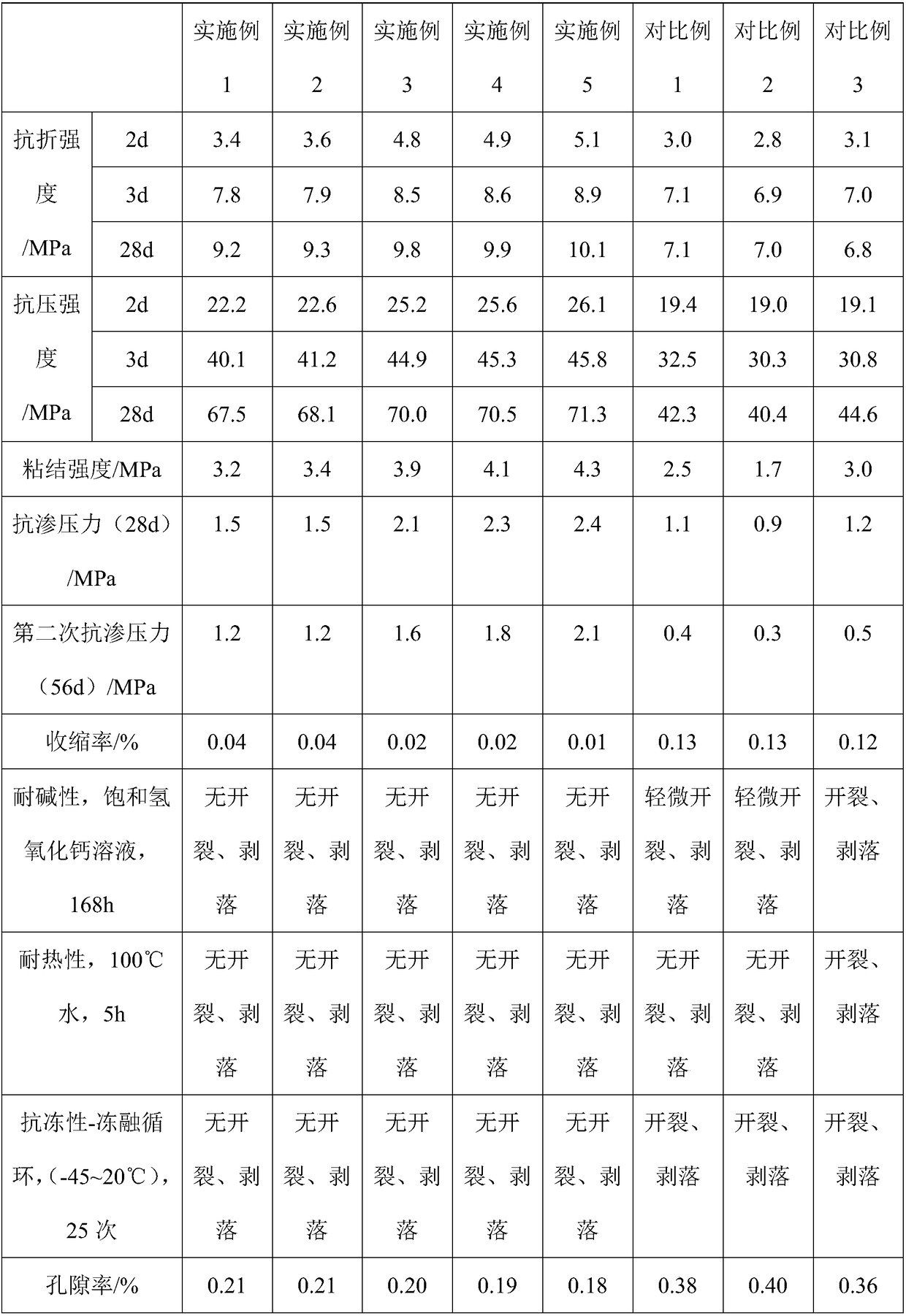

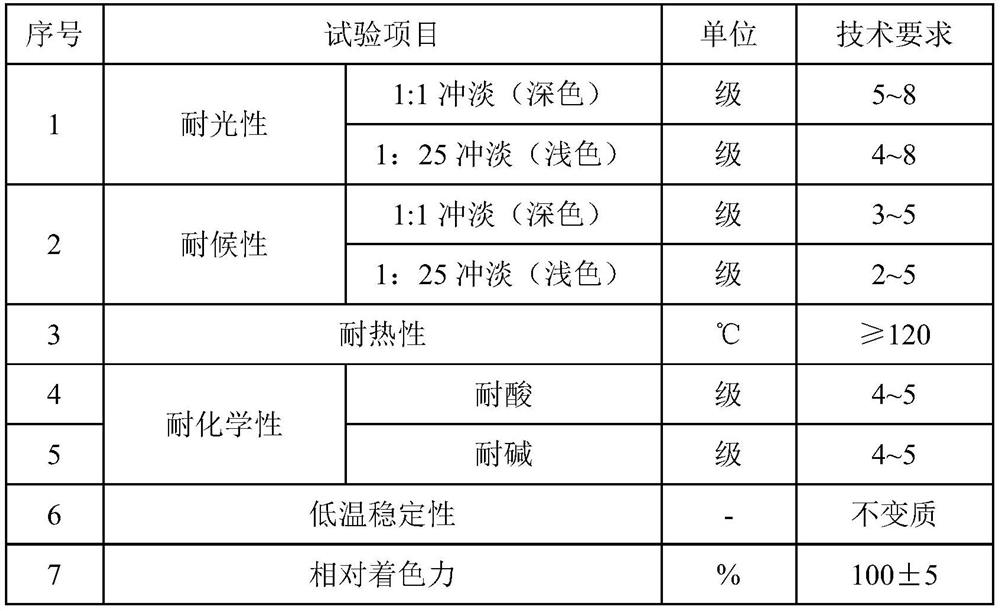

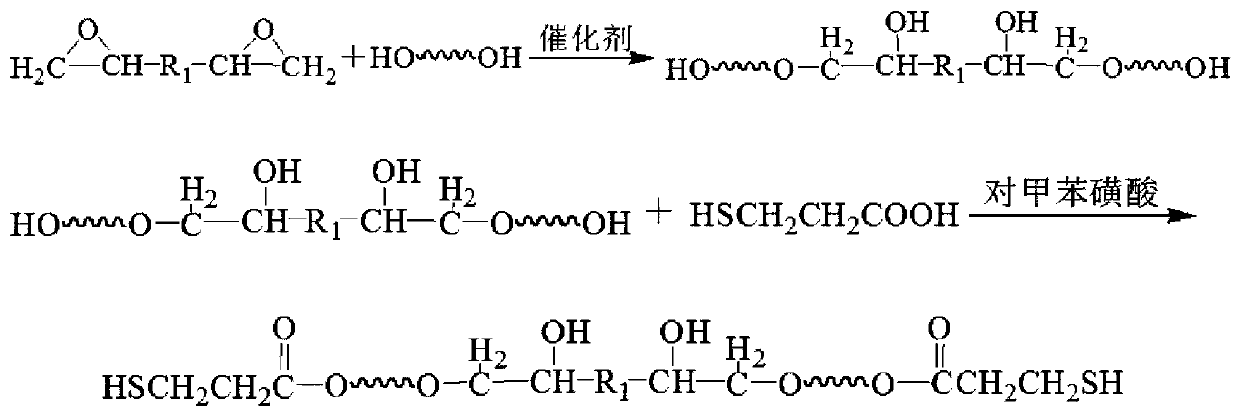

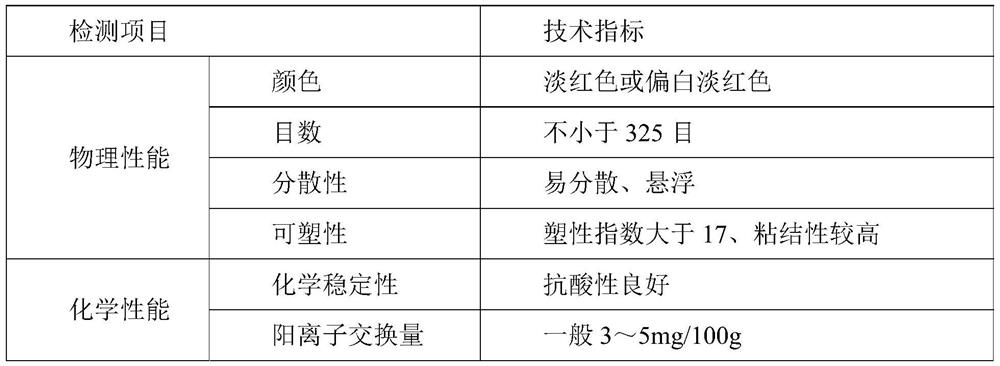

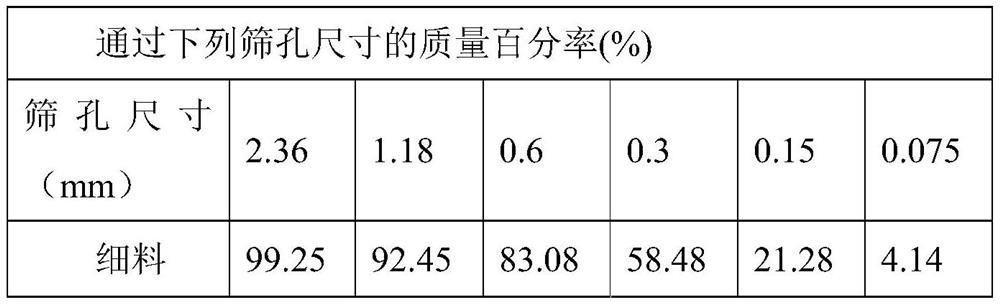

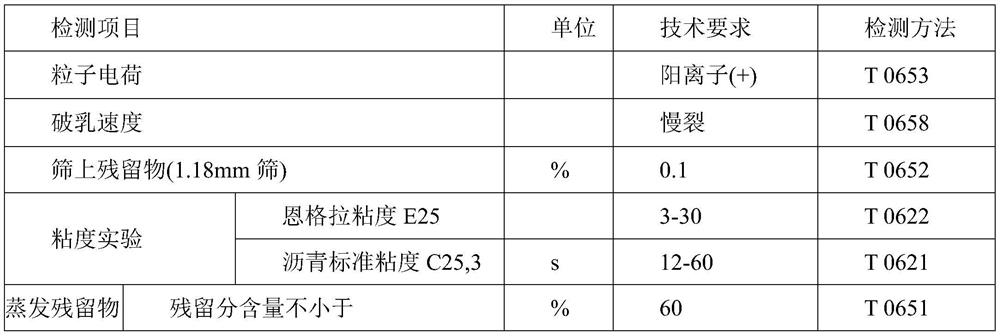

Slow breaking and quick setting cationic asphalt emulsifier and preparation method thereof

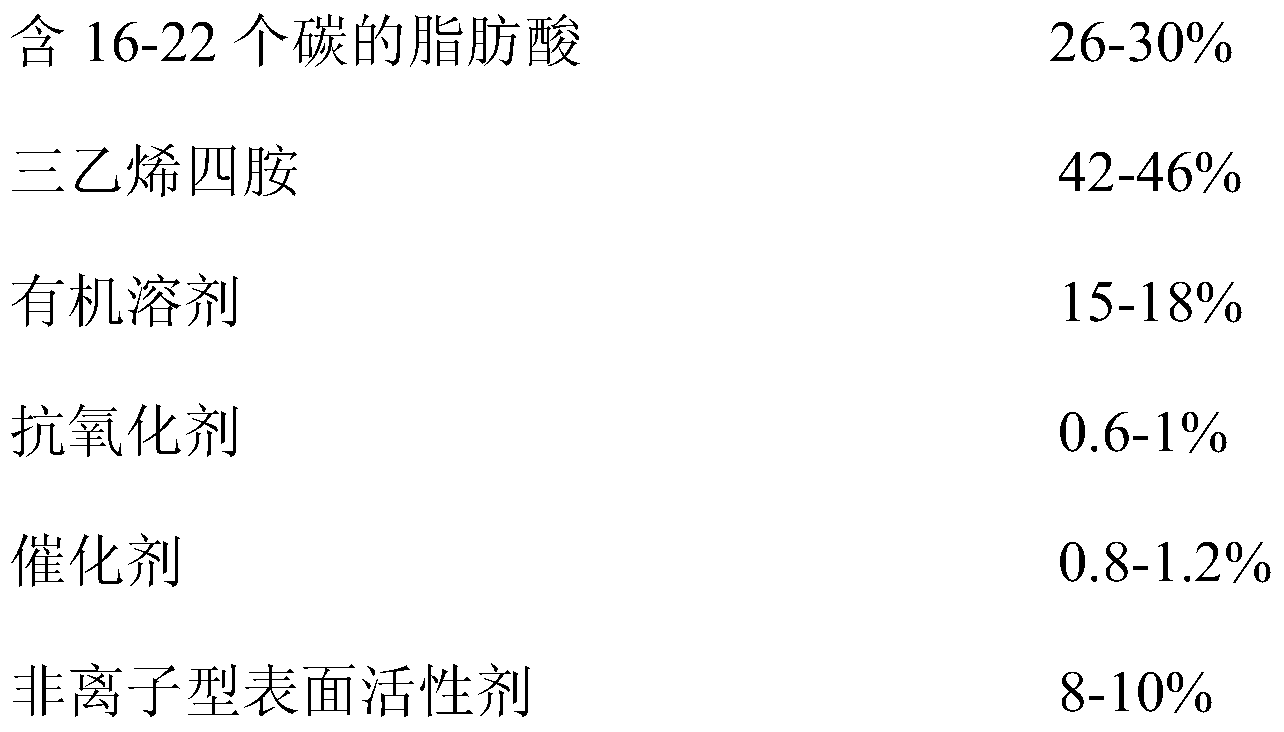

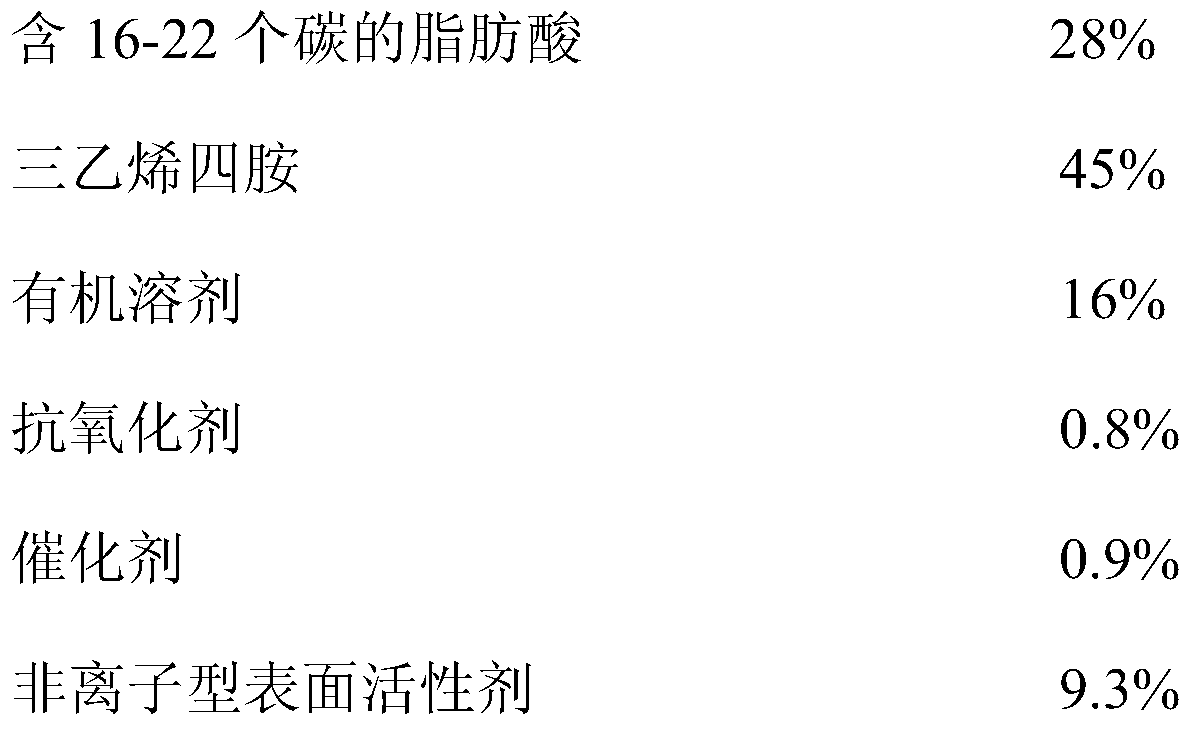

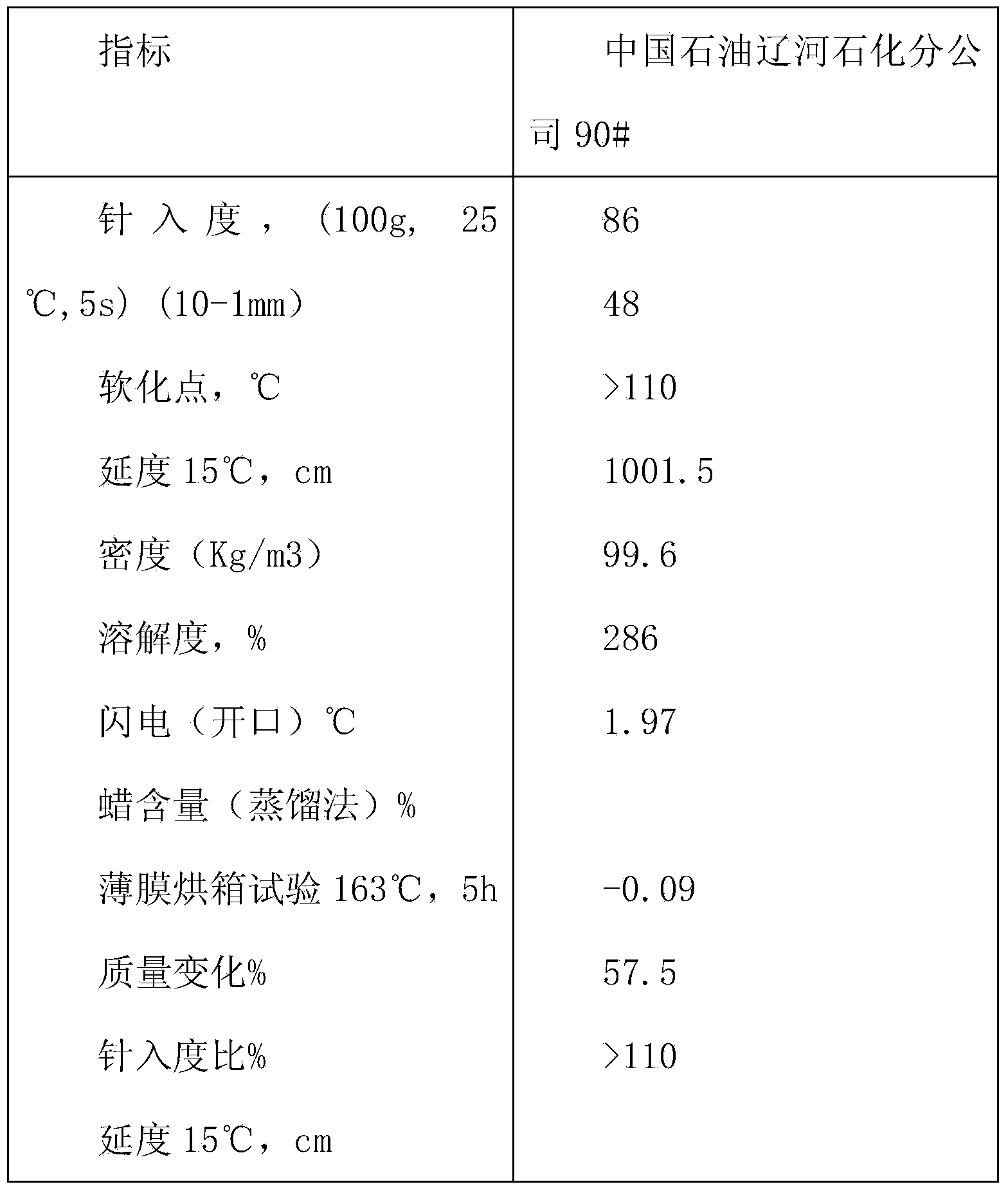

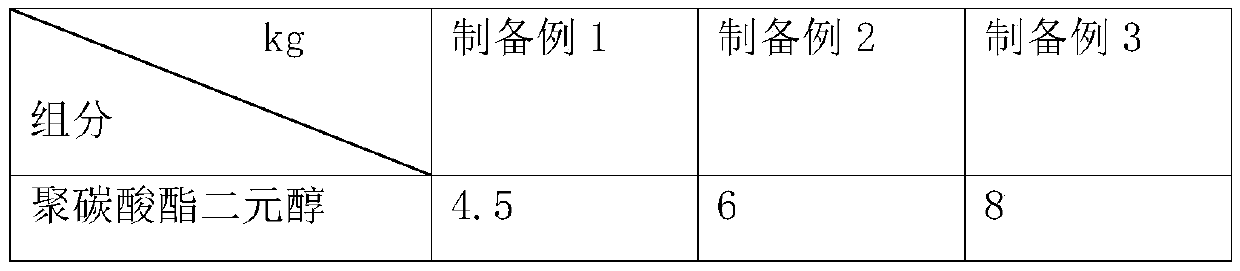

InactiveCN103923325AImprove work efficiencyStrong emulsifying abilityBuilding insulationsChemistryTetramine

The invention discloses a slow breaking and quick setting cationic asphalt emulsifier, consisting of the following components: fatty acid containing 16-22 carbons, triethylene tetramine, organic solvent, antioxidant, catalyst and nonionic surfactant. In the preparation process of the slow breaking and quick setting cationic asphalt emulsifier, the asphalt emulsifier is prepared by adopting a microwave heating technology, so that the synthesis time is 2.5-3h shorter than the traditional time. When the emulsified asphalt prepared from the slow breaking and quick setting cationic asphalt emulsifier is used for a thin slurry sealing layer, the consumption is 0.8-1.2%; moreover, a pavement can be quickly set, the open traffic time can be shortened to 30-40min, and quick traffic can be realized. The asphalt content of the emulsified asphalt prepared from the slow breaking and quick setting cationic asphalt emulsifier can reach 70%. The whole synthesis process does not pollute the ambient environment.

Owner:抚顺职业技术学院

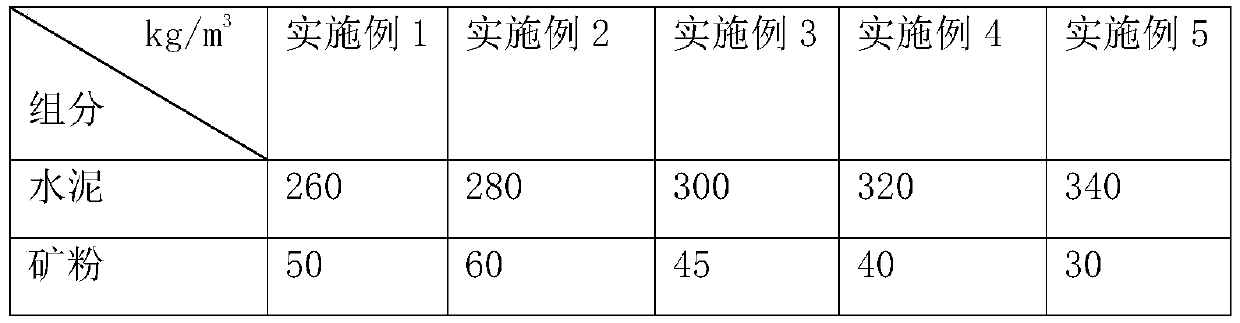

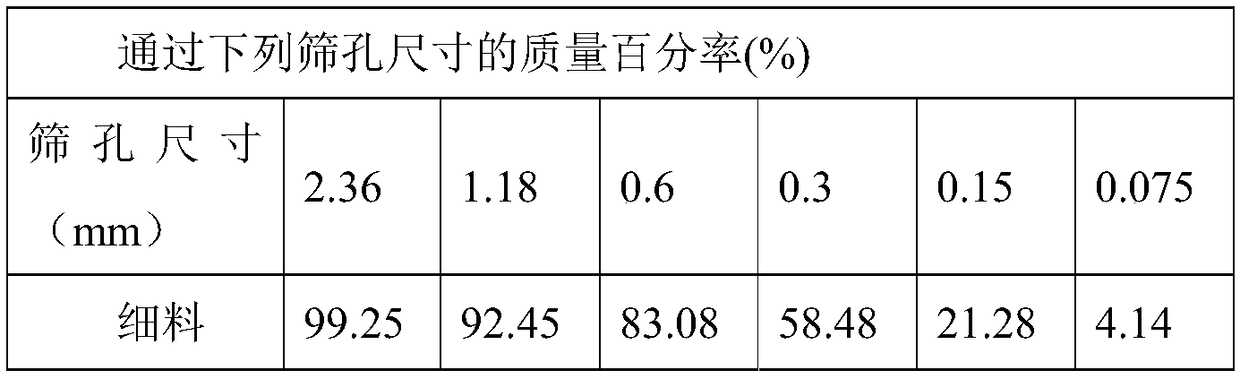

Colored pervious concrete and preparation process thereof

The invention discloses a colored pervious concrete and a preparation process thereof. The colored pervious concrete is prepared from the following raw materials in parts by weight: 260 to 340 parts of cement; 30 to 60 parts of mineral powder; 60 to 90 parts of fly ash, 20 to 45 parts of silica fume, 150 to 200 parts of water, 700 to 900 parts of a fine aggregate, 800 to 1200 parts of a coarse aggregate, 10 to 20 parts of a pigment, 8 to 16 parts of an early strength accelerator, 45 to 80 parts of bisphenol A epoxy resin, 35 to 55 parts of polyurethane modified gelatin and 60 to 90 parts of acuring accelerator; wherein the curing accelerator is prepared from 2-ethyl-4-methylimidazole, a modified anhydride curing agent and a cardanol modified polyamide in a mass ratio of 1 to (1.3 to 1.5)to (0.7 to 1). The colored pervious concrete has the advantages of being high in pervious coefficient, high in early compressive strength and breaking strength, short in curing time, capable of shortening open traffic time and good in thermal aging resistance and freezing and thawing resistance.

Owner:成都新豪鼎盛建材有限公司

Environment-friendly nonslip ultrathin seal material and preparation method thereof

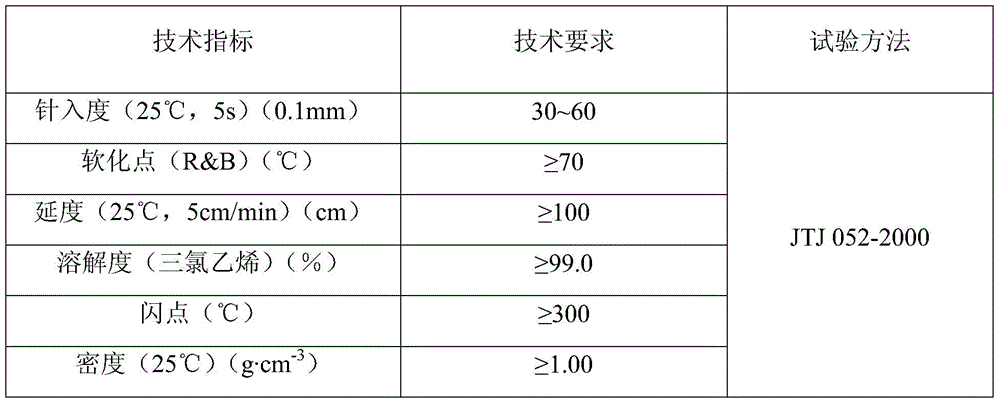

ActiveCN109486421AHigh softening pointHigh viscosityAntifouling/underwater paintsPaints with biocidesRoad surfaceConstruction aggregate

The invention discloses an environment-friendly nonslip ultrathin seal material and a preparation method thereof and solves the problems that the asphalt pavement has water penetration, poor slip resistance, slightly pitted surface and small cracks. A stable durable seal is provided to protect the asphalt pavement, aggregate of an original asphalt pavement can be locked, oil shortage can be repaired, post-construction traffic opening time is short, little influence is caused to transportation, and the material herein has great technical significance and social significance; the preventive maintenance process used herein helps maintain pavement service level and retard maintenance time of extensive and medium repair, and save lifecycle maintenance cost.

Owner:中山市易路美智能装备有限公司 +1

Geopolymer-based cement pavement crack quick repair material, method for preparing same and application of geopolymer-based cement pavement crack quick repair material

The invention discloses a geopolymer-based cement pavement crack quick repair material, a method for preparing the same and application of the geopolymer-based cement pavement crack quick repair material. The geopolymer-based cement pavement crack quick repair material comprises, by weight, 10-25 parts of alkali activators, 45-65 parts of metakaolin, 0.1-0.5 part of silica fume, 1-2 parts of water, 0.1-0.5 part of water reducing agents, 1-5 parts of silicate cement, 1-2parts of rice husk ash, 0.1-0.5 part of rice straw fibers and 0.5-1 part of silane coupling agents. The geopolymer-based cement pavement crack quick repair material, the method and the application have the advantages of high strength, short traffic opening time, good durability, strong new-old concrete interface action and low cost.

Owner:湖北恒畅路桥有限公司

Method for repairing expressway pavement

InactiveCN107117898AImprove liquidityQuick and effective patchingIn situ pavingsPortland cementPolystyrene

The invention discloses a method for repairing an expressway pavement. The method comprises the following steps: weighing the following raw materials in parts by weight: 55-65 parts of Portland cement, 78-86 parts of gravel, 21-29 parts of polystyrene resins, 8-16 parts of fatty alcohol-polyoxyethylene ether, 16-24 parts of calamine, 11-19 parts of chitin, 20-28 parts of sodium hydroxide and 40-50 parts of tartaric acid; grinding and mixing the polystyrene resins, fatty alcohol-polyoxyethylene ether, calamine and chitin; adding the Portland cement, gravel and sodium hydroxide respectively for uniformly stirring, adding water for stirring and standing, and adding tartaric acid for stirring and standing so as to obtain a repair material; pouring the repair material onto a damaged pavement, leveling, and maintaining, thereby completing repair. The material disclosed by the invention is used for rapid and efficient repair of the expressway pavement, the process is simple and feasible, rolling is not needed, and all that is needed is simple paving and flattening. According to the concrete pavement repair method disclosed by the invention, the pavement can be open to traffic after being repaired within an hour, the traffic opening time can be greatly shortened, and repeated repair is not needed after one-step repair.

Owner:李仲来

Repair material for extremely cold pavement as well as preparation method and application of repair material

The invention discloses a repair material for an extremely cold pavement as well as a preparation method and an application of the repair material. The repair material is prepared from raw materials in parts by weight as follows: 60-70 parts of Portland cement, 32-40 parts of fine sand, 11-19 parts of sodium gluconate, 18-26 parts of diethylenetriamine and 23-31 parts of polyketone resin. Diethylenetriamine is mixed with ethanol which is 3.5-4 time the mass of diethylenetriamine, and a diethylenetriamine solution is prepared for standby application; polyketone resin is heated to 65-70 DEG C, heated and stirred for 30-35 min at the temperature and then heated to 78 DEG C, the diethylenetriamine solution is added, a mixed solution is subjected to sealed heating and stirring for 0.7-0.8 h atthe temperature of 78 DEG C, and a mixture is prepared; the Portland cement, the fine sand and sodium gluconate are mixed and stirred uniformly, the mixture is added, stirring is executed for 1.1-1.2h, and the repair material is obtained. The repair material has good low-temperature crack resistance, high-temperature stability, interface bonding property, aging resistance and anti-fatigue performance and high liquidity, the pavement can be open to traffic 0.7 h after being repaired with the repair material, and accordingly, the repair material is applicable to repair for cracks and seams of the cement concrete pavement under extremely cold weather conditions.

Owner:祎禾科技有限公司

Fly ash-based geopolymer mortar repairing material and preparation method thereof

InactiveCN111635171AHigh strengthShort opening hours for trafficCement productionGeopolymer mortarRepair material

The invention belongs to the technical field of road repairing materials, and concretely relates to a fly ash-based geopolymer mortar repairing material and a preparation method thereof. The repairingmaterial is prepared from, by weight, 32 to 45 parts of low-calcium fly ash, 8 to 12 parts of a water glass solution, 3 to 4 parts of NaOH, 1 to 2 parts of nanometer silicon dioxide gel, 1.6 to 2.5 parts of a steel fiber, 0.2 to 0.3 part of a calcium carbonate whisker, 8 to 11 parts of pure water and 64 to 90 parts of medium sand. The geopolymer mortar repairing material has the characteristics of cleanness, greenness, high strength, short open traffic time, good durability, strong interface effect of new and old concrete and good shrinkage performance.

Owner:ZHEJIANG SCI-TECH UNIV

Fly ash based geopolymer mortar repairing material and preparation method thereof

InactiveCN112551953AHigh strengthShort opening hours for trafficCement productionRepair materialGeopolymer mortar

The invention belongs to the technical field of road repairing materials, and particularly relates to a fly ash based geopolymer mortar repairing material and a preparation method thereof; the fly ashbased geopolymer mortar repairing material comprises the following components in parts by weight: 32-45 parts of low-calcium fly ash, 8-12 parts of water glass solution, 3-4 parts of NaOH, 1-2 partsof nano silicon dioxide gel, 1.6-2.5 parts of steel fibers, 0.2-0.3 part of calcium carbonate whiskers, 8-11 parts of pure water and 64-90 parts of medium sand. The geopolymer mortar repairing material disclosed by the invention has the characteristics of cleanness, greenness, high strength, short open traffic time, good durability, strong interface effect of new and old concrete and good shrinkage performance.

Owner:ZHEJIANG SCI-TECH UNIV

Aqueous polymer binder, colorful sealing layer mixture, and preparation method

The invention provides an aqueous polymer binder, and a colorful sealing layer mixture. The aqueous polymer binder comprises, by mass, a polymer modified petroleum resin emulsion of 15%-45%, water of15%-30%, mineral material of 10%-30%, a filler of 5%-20%, an anti-ultraviolet color paste of 1%-15%, a dispersant of 1%-5%, a bactericidal preservative of 0-2%, a thickening agent of 0.5%-5%, a defoaming agent of 0.2%-5%, and a surfactant of 1%-10%. The aqueous polymer binder possesses the rigidity, weather resistance and durability of inorganic materials, and the bonding force and flexibility oforganic high molecular materials, is capable of realizing synchronous shrinkage with pavement, possesses permanent clunging force, is aqueous, is friendly to the environment, is nontoxic, and is odourless; and cracking is not caused.

Owner:中山市易路美智能装备有限公司 +1

High-strength and high-toughness epoxy resin concrete for bridge expansion joint transition zone and preparation method thereof

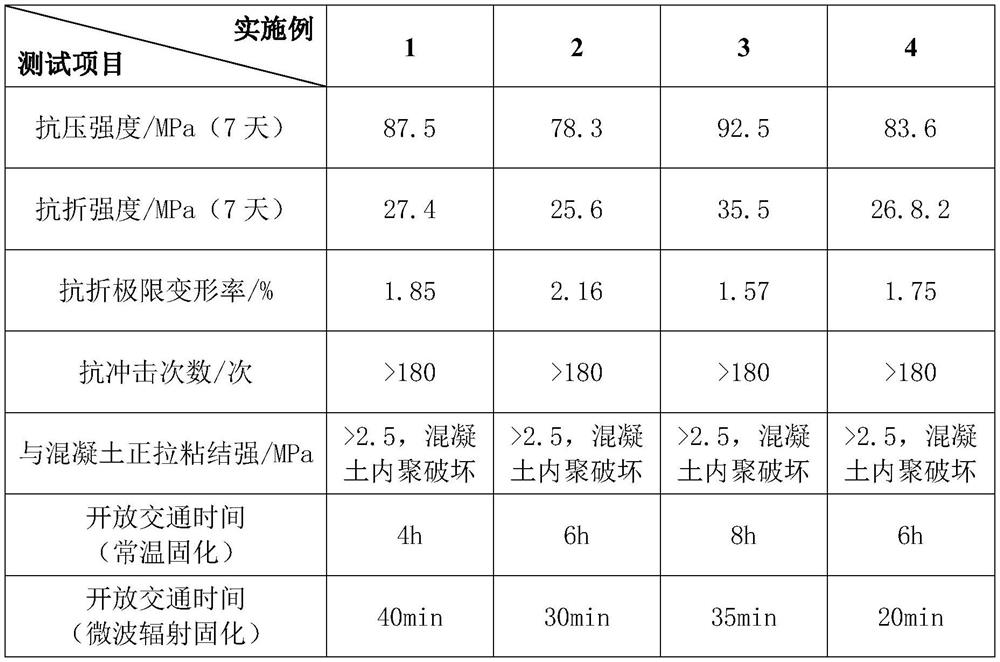

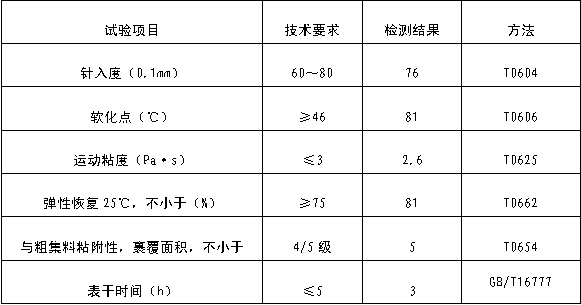

The invention discloses a high-strength and high-toughness epoxy resin concrete for bridge expansion joint transition zones and a preparation method thereof. The epoxy resin concrete consists of a component A, a component B and a component C; the component A is prepared from nanoscale rubber-modified epoxy resin, liquid bisphenol-A epoxy resin, epoxy active diluent, defoaming agent and dispersant;the component B is prepared from epoxy curing agent, curing accelerant, coupling agent and pigment; and the component C is prepared from sand, quartz powder, fly ash, waste rubber powder, magnet powder and chopped fibers. The high-strength and high-toughness epoxy resin concrete not only can be cured by normal temperature but also can be cured by microwave radiation. The high-strength and high-toughness epoxy resin concrete has the advantages of good durability, long life, comfort for driving, short time for being open to traffic, constructability in low-temperature environments and the like,can be used in the installation construction of bridge expansion joints as well as the rapid concrete repair of bridge expansion joint transition zones, and can solve the problems of conventional bridge expansion joint transition zone concretes, i.e., short lives and long time for being open to traffic.

Owner:山西省交通科技研发有限公司

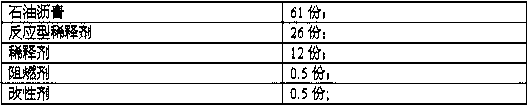

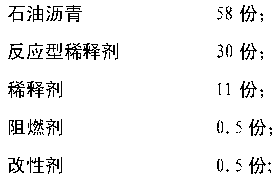

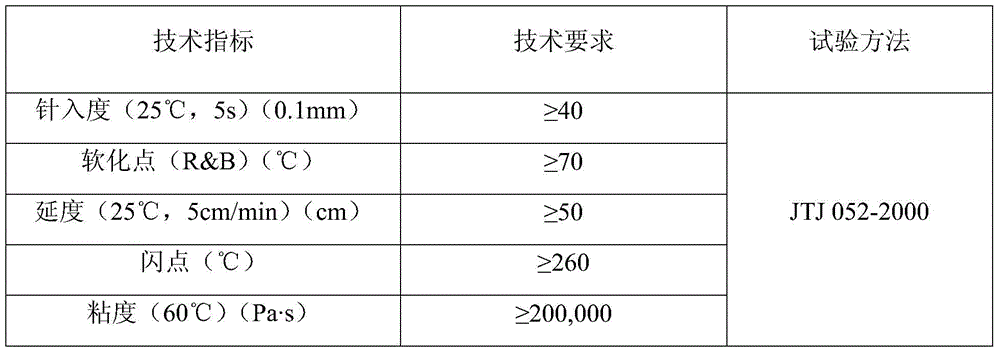

A kind of preparation method of high-strength cold paved asphalt mixture

ActiveCN104610769BImprove liquidityMeet mixing requirementsBuilding insulationsDiluentReactive diluent

The invention relates to normal-temperature-modified asphalt for a high-strength cold-laid asphalt mixture and a preparation method of normal-temperature-modified asphalt. The normal-temperature-modified asphalt for the high-strength cold-laid asphalt mixture comprises the following components in parts by weight: 58-64 parts of petroleum asphalt, 21-30 parts of a reactive diluent, 11-14 parts of a diluents, 0.01-1 part of a flame retardant and 0.01-1 part of a modifier. The normal-temperature-modified asphalt is small in viscosity at normal temperature and has good construction workability; the softening point of the normal-temperature-modified asphalt is higher than that of ordinary petroleum asphalt and the normal-temperature-modified asphalt has the advantages of large elastic recovery rate, short surface drying time, high curing-molding rate and strong coating force with an aggregate. The cold-laid asphalt mixture prepared from the normal-temperature-modified asphalt has the advantages of high early strength forming speed after paving, high molding strength and short open transportation time compared to the conventional cold-mixing asphalt mixture and meanwhile, the high temperature performance, water stability and the low-temperature performance can reach the technical requirements of the hot-mixing asphalt mixture and the preparation method is simple, economic, environmentally friendly and energy-saving.

Owner:BEIJING MUNICIPAL ENG RES INST +1

A repair material for extremely cold pavement and its preparation method and application

The invention discloses a repair material for an extremely cold pavement as well as a preparation method and an application of the repair material. The repair material is prepared from raw materials in parts by weight as follows: 60-70 parts of Portland cement, 32-40 parts of fine sand, 11-19 parts of sodium gluconate, 18-26 parts of diethylenetriamine and 23-31 parts of polyketone resin. Diethylenetriamine is mixed with ethanol which is 3.5-4 time the mass of diethylenetriamine, and a diethylenetriamine solution is prepared for standby application; polyketone resin is heated to 65-70 DEG C, heated and stirred for 30-35 min at the temperature and then heated to 78 DEG C, the diethylenetriamine solution is added, a mixed solution is subjected to sealed heating and stirring for 0.7-0.8 h atthe temperature of 78 DEG C, and a mixture is prepared; the Portland cement, the fine sand and sodium gluconate are mixed and stirred uniformly, the mixture is added, stirring is executed for 1.1-1.2h, and the repair material is obtained. The repair material has good low-temperature crack resistance, high-temperature stability, interface bonding property, aging resistance and anti-fatigue performance and high liquidity, the pavement can be open to traffic 0.7 h after being repaired with the repair material, and accordingly, the repair material is applicable to repair for cracks and seams of the cement concrete pavement under extremely cold weather conditions.

Owner:祎禾科技有限公司

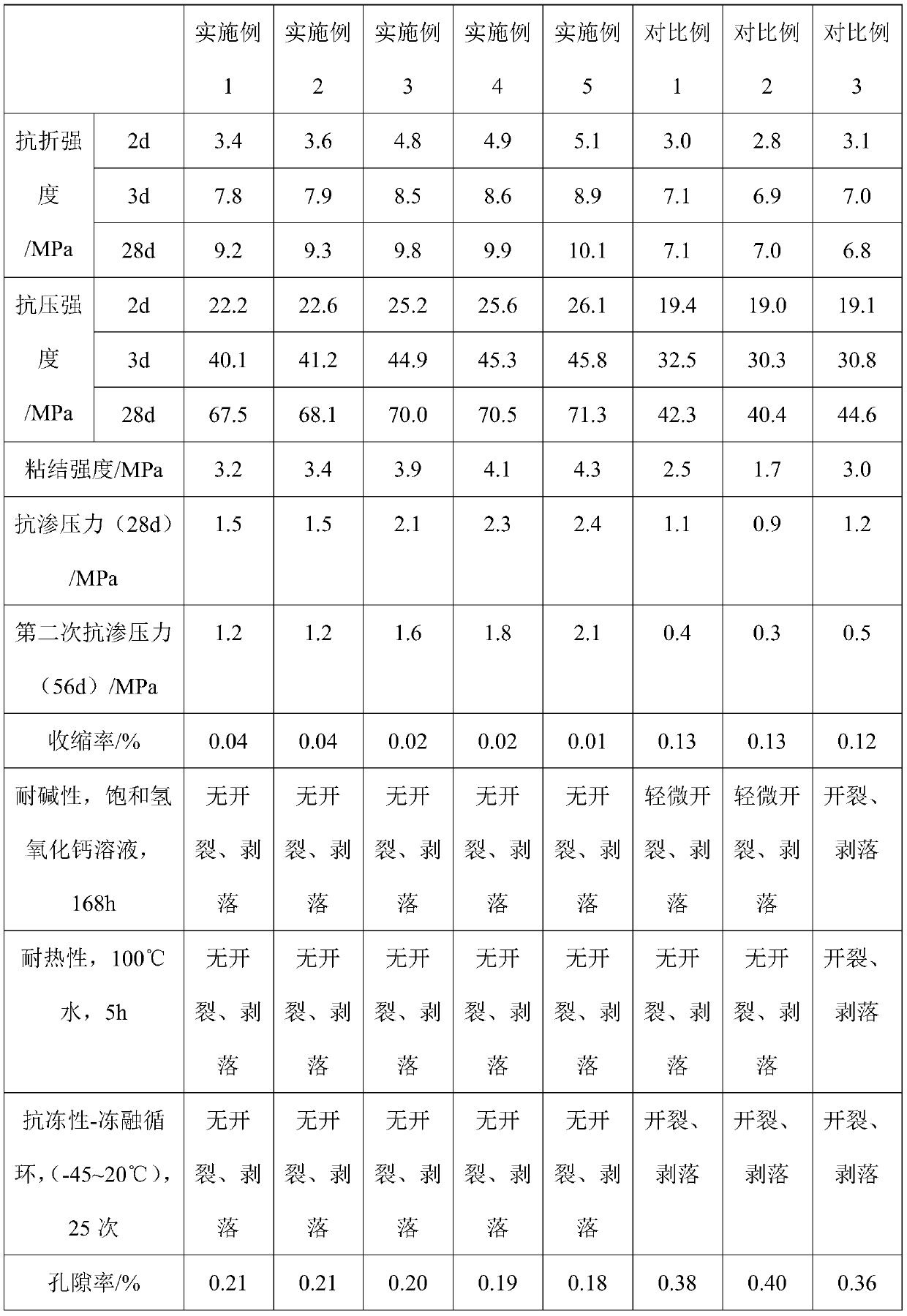

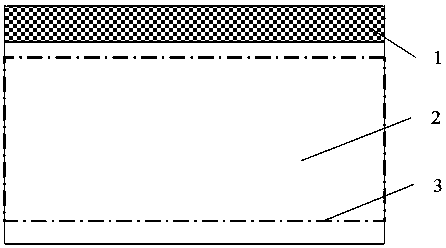

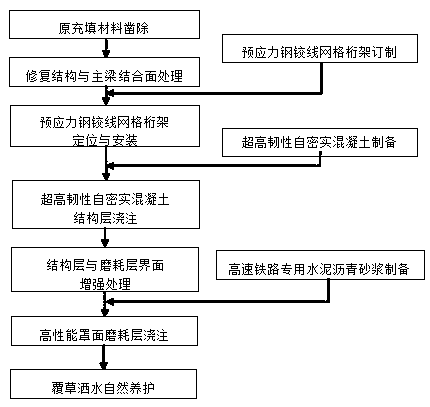

A Repairing Structure and Construction Method of Expansion Joint Transition Area of Expressway Concrete Bridge

ActiveCN106894332BImprove wear resistanceReduce local network breaksBridge structural detailsBridge erection/assemblyPre stressPre stressing

The invention provides a motorway concrete bridge telescopic seam transition area restoration structure and a construction method. The motorway concrete bridge telescopic seam transition area restoration structure and the construction method are characterized in that the restoration structure designed through the construction method is composed of a high-performance wearing layer (1) and a superhigh-toughness self-compacting concrete structure layer (2); the high-performance wearing layer (1) is arranged on the superhigh-toughness self-compacting concrete structure layer (2) in a covering mode; and the superhigh-toughness self-compacting concrete structure layer (2) is internally equipped with a pre-stressed steel stranded wire truss (3). By adoption of the motorway concrete bridge telescopic seam transition area restoration structure and the construction method, comprehensive mechanical performance such as fracture toughness and impact resistance and durability of the motorway concrete bridge telescopic seam transition area restoration structure can be remarkably improved, and the traffic opening time is short.

Owner:江西省高等级公路管理局泰井高速公路管理处养护中心 +1

Pavement patching material and preparation method thereof

The invention relates to a pavement patching material and a preparation method. The pavement patching material is characterized in that, in parts by weight, it comprises 40-68 parts of manganese slag, 32-56 parts of red mud, 16-34 parts of alkaline activator, 2-7 parts of silica fume, and 20-36 parts of calcium oxide. 10-16 parts of water. The pavement patching material of the invention can effectively utilize industrial waste residues to realize rapid hardening and early strength, has short opening time for traffic, has low pollution and energy consumption in the production process, and has low production cost.

Owner:湖南鑫长胜材料科技有限公司 +2

Water-based polymer binder, color sealing compound and preparation method thereof

The invention provides a water-based polymer binder and a color sealing layer mixture, wherein the binder, in terms of mass percentage, comprises the following raw materials: polymer modified petroleum resin emulsion 15%-45%, water 15%-30% %, 10%~30% of mineral material, 5%~20% of filler, 1%~15% of anti-ultraviolet color paste, 1%~5% of dispersant, 0~2% of bactericide and preservative, 0.5%~5% of thickener %, defoamer 0.2% to 5%, surfactant 1% to 10%. The product of the invention not only has the rigidity and weather resistance durability of inorganic materials, but also combines the binding force and flexibility of organic polymer materials. Poisonous and tasteless.

Owner:中山市易路美新材料科技有限公司 +1

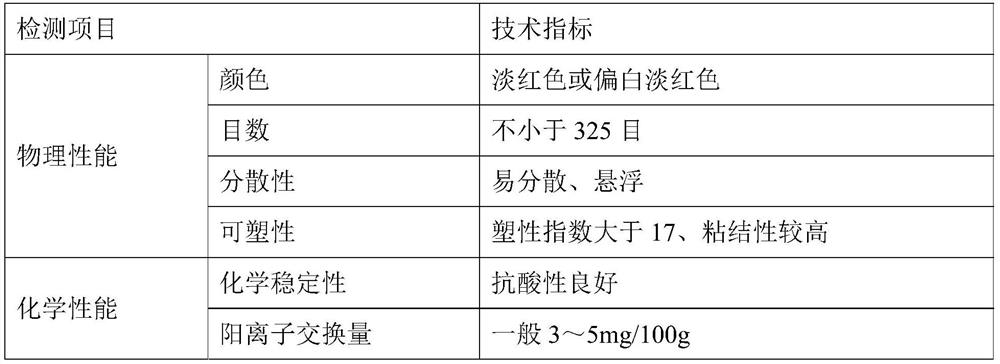

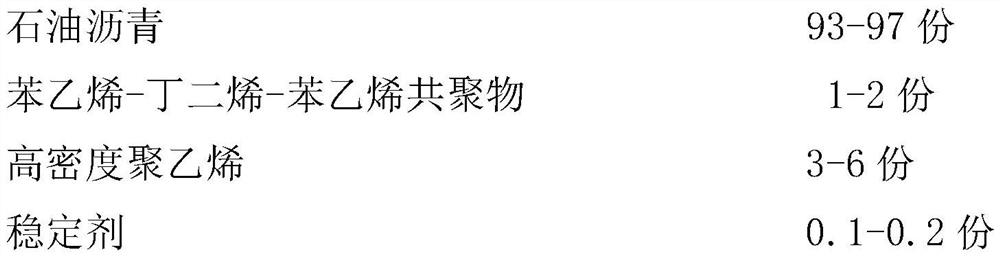

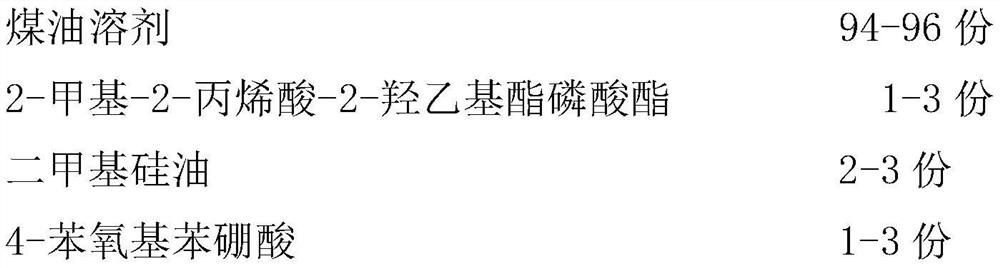

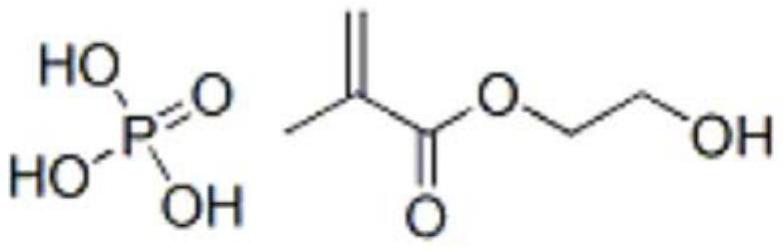

A kind of adhesive layer oil with self-healing characteristics and preparation method thereof

ActiveCN113388363BIncrease elasticityImprove flow wettabilityNon-macromolecular adhesive additivesBituminous material adhesivesPolymer sciencePolyolefin

The invention discloses a self-healing viscous layer oil and a preparation method. The raw materials are composed of two components. Component 1 includes 93-97 parts of petroleum asphalt, 1-2 parts of styrene-butadiene-styrene copolymer, 3-6 parts of polyolefin, and 0.1-0.2 parts of stabilizer; Component 2 includes 2 parts of dimethyl silicone oil -3 parts, 94-96 parts of kerosene solvent, 1-3 parts of 4-phenoxyphenylboronic acid, and 1-3 parts of flame retardant. The petroleum asphalt is heated, and styrene-butadiene-styrene copolymer and polyolefin are respectively added to it and stirred and sheared, then a stabilizer is added, and stirring is continued to develop and swell to obtain component 1; add two to the kerosene solvent. Methyl silicone oil, 4-phenoxybenzene boronic acid and flame retardant are stirred to obtain component 2, and component 1 and component 2 are mixed and diluted in a ratio of 1:1 to 1:1.5, and stirred, A viscous layer oil with self-healing characteristics is obtained. The invention has the characteristics of high-strength interlayer bonding performance, high self-healing property under normal temperature conditions, repeated bonding and strong environmental protection.

Owner:上海缤德新材料科技有限公司

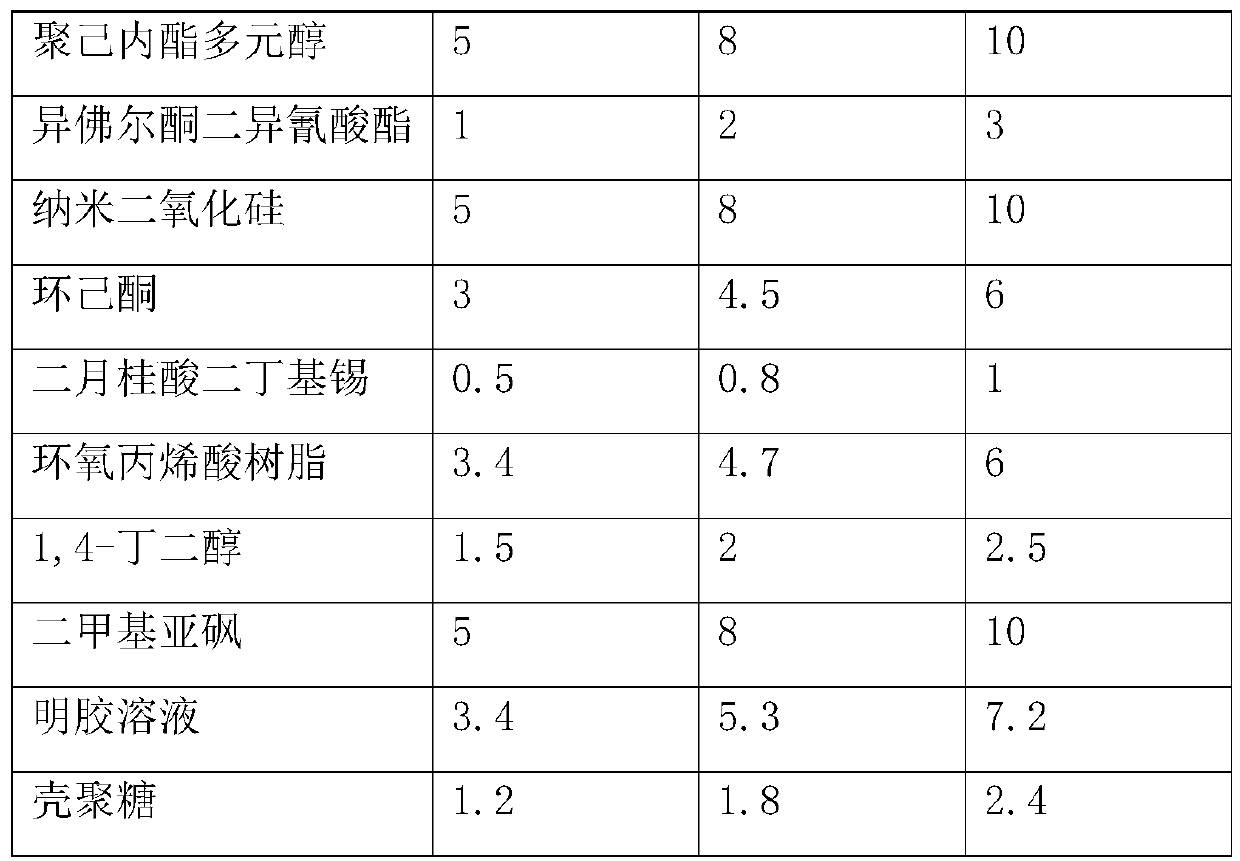

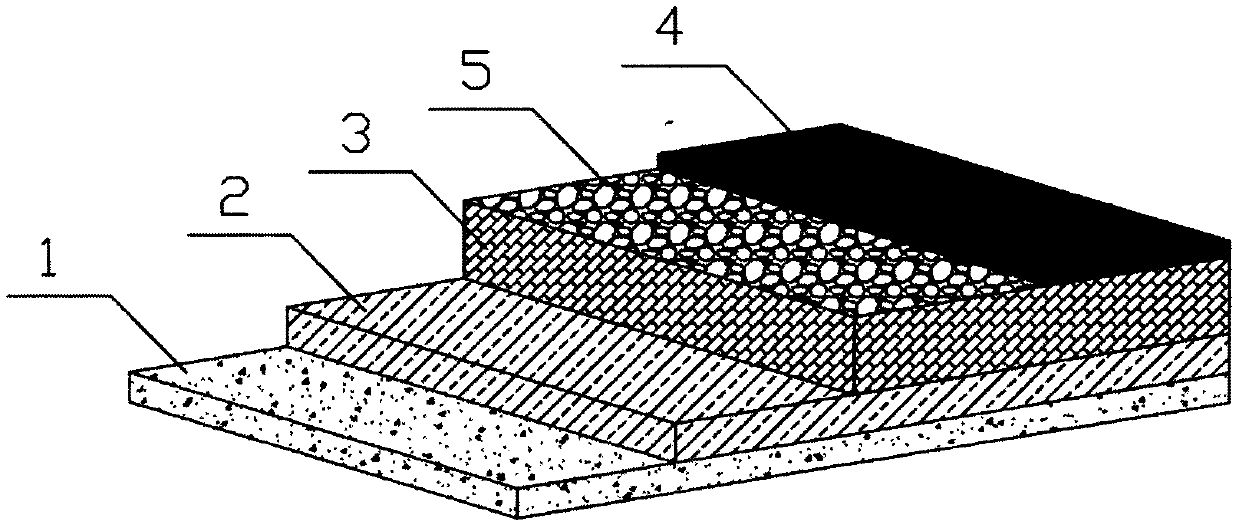

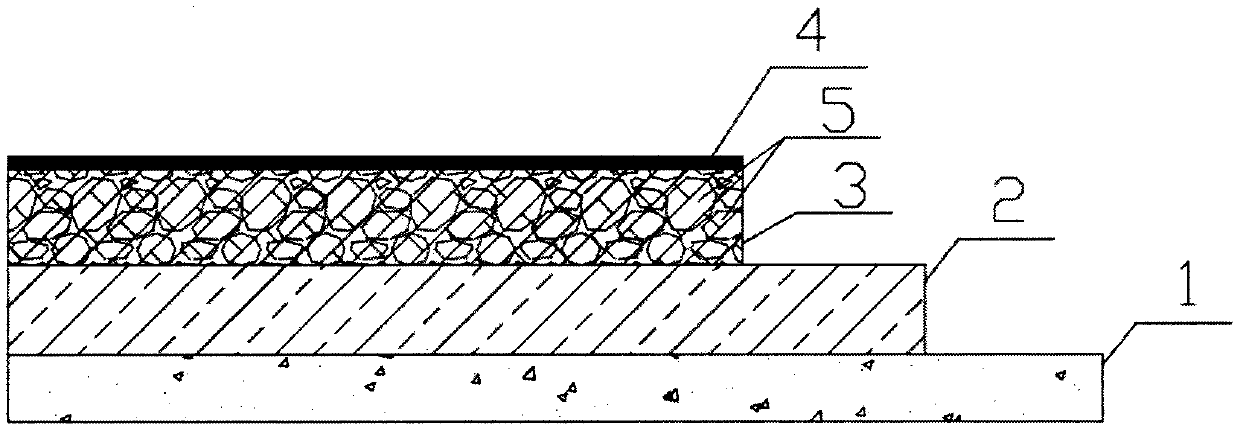

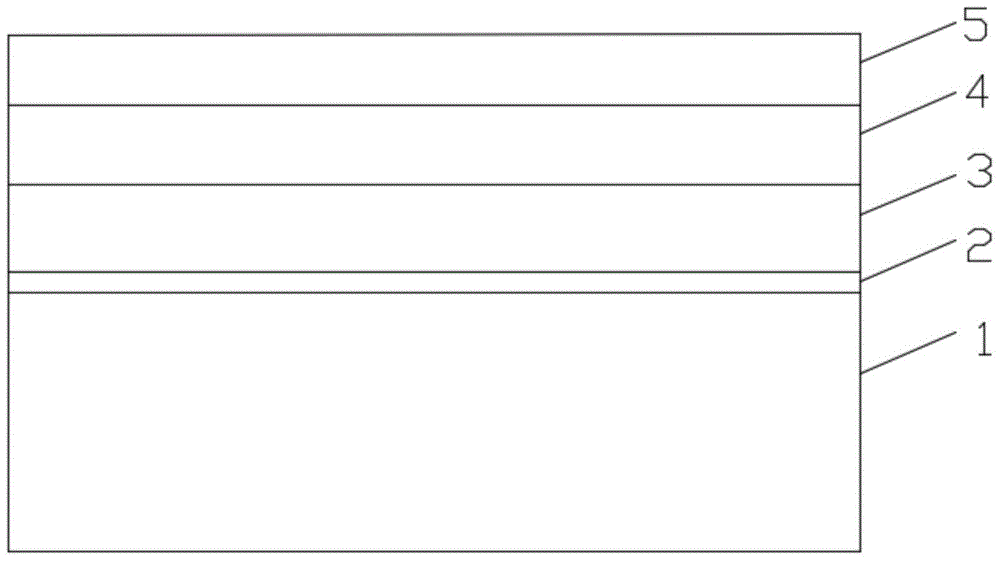

Novel epoxy resin bicycle lane thin-layer pavement structure

PendingCN110485233AReduce construction costsReduce water permeabilitySingle unit pavingsPaving detailsEpoxyWear resistant

The invention discloses a novel epoxy resin bicycle lane thin layer pavement structure, which belongs to the technical field of road engineering, and which is a layered composite structure, and the structure sequentially comprises an impermeable bonding layer, an antiskid wear-resistant layer and a sealing layer from bottom to top, wherein the impermeable bonding layer is prepared from polyurethane modified epoxy resin, the antiskid wear-resistant layer is prepared from a mixture of polyurethane modified epoxy resin and quartz sand and ceramic particles, and the sealing layer is prepared fromthe polyurethane modified epoxy resin. The invention provides the novel epoxy resin bicycle lane thin layer pavement structure. The thin-layer pavement structure is light and thin in structure, simpleand convenient to construct and concise in appearance; the bonding strength of the thin-layer pavement structure and a bicycle concrete pavement slab is particularly outstanding, the synergistic effect between the pavement slab and a pavement layer is effectively improved, and the thin-layer pavement structure has the advantages of excellent impermeability, skid resistance, wear resistance, durability and the like.

Owner:NANJING FORESTRY UNIV

A bridge expansion joint transition area pouring material and its preparation method and construction process

Belonging to the technical field of chemical building materials, the invention discloses a perfusion material for a bridge expansion joint transition region, and a preparation method and construction process thereof. The perfusion material consists of three components, A, B and C. The component A consists of epoxy resin, an epoxy active diluent, a superfine waste rubber powder, an antifoaming agent and a dispersing agent; the component B consists of a curing agent, a curing agent promoter and a coupling agent; and the component C consists of waste rubber particles, a waste rubber powder and whiskers. The component A and component B are mixed and stirred evenly, and then the component C is added and mixed evenly to obtain the perfusion material. In construction, first a contact surface of a reserved groove of the bridge expansion joint and the perfusion material is coated with a layer of adhesive, and then the perfusion material is poured into reserved groove of the bridge expansion joint. The perfusion material prepared by the invention has high bonding strength, good construction performance, short time before traffic usage, good wear resistance, shock absorption and noise reduction performances, high mechanical properties, excellent impact resistance and durability, and substantial environmental benefits.

Owner:山西省交通科技研发有限公司

A kind of repair material for quickly repairing pavement and its preparation method and application

ActiveCN108083735BImprove adhesionQuick and effective patchingIn situ pavingsHexamethylenetetraminePortland cement

The invention discloses a repair material for quickly repairing a pavement as well as a preparation method and application thereof. The repair material comprises the following raw materials in parts by weight: 38-46 parts of Portland cement, 17-25 parts of fine sand, 9-17 parts of vinyl acetate resin, 3-7 parts of polyoxyethylene ether, 13-21 parts of a mixture of rice chaffs and husks and 15-25 parts of hexamethylenetetramine. The preparation method comprises the following steps: mixing the vinyl acetate resin and the mixture of rice chaffs and husks, then crushing, increasing the temperatureto 58-62 DEG C, heating and stirring for 20-25 minutes at the temperature of 58-62 DEG C, then increasing the temperature to 76 DEG C, adding a hexamethylenetetramine solution and hermetically heating and stirring for 0.9-1 hour at the temperature of 76 DEG C to prepare a mixture; mixing and uniformly stirring the Portland cement, the fine sand and the polyoxyethylene ether, then adding the mixture and stirring for 1.9-2 hours to obtain the repair material. The repair material as well as the preparation method and the application thereof, disclosed by the invention, has the benefits that therepair material is suitable for repairing cracks and joints of the cement concrete pavement under very cold weather conditions, the pavement can be open to traffic after being repaired for 0.5 hour, the traffic opening time can be greatly shortened, and the repeated repairs are not needed after one-time repair.

Owner:贵州雷氏兄弟建材有限公司

A kind of cement concrete pavement repair material and preparation method thereof

The invention discloses a cement concrete pavement repair material and a preparation method of same. The material includes, by weight, 55-63 parts of Portland cement, 18-26 parts of akadama, 47-55 parts of sand and stone, 9-17 parts of casein, 11-19 parts of polyethylene glycol terephthalate, and 16-24 parts of polylactic acid. The preparation method includes the steps of: crushing and uniformly mixing the akadama, casein, polyethylene glycol terephthalate and polylactic acid, adding the Portland cement, and uniformly mixing the components; and adding the sand and stone and a NaOH water solution, mixing and stirring the mixture and allowing the mixture to stand. The material has excellent low-temperature anti-cracking property, high temperature stability, interface adhesivity, anti-aging property, anti-fatigue performance and high flowability, is suitable for repairing seams and joints on a cement concrete pavement under an extreme cold weather condition. The repair material can restore traffic after the pavement is repaired therewith for 1 h, so that traffic recovery time is greatly reduced. The repair material is free of repeated maintenance when being used for repairing the pavement for one time, and can effectively improve anti-damage property of the pavement, thus prolonging service life of roads.

Owner:广东嘉集建筑工程有限公司

A kind of asphalt pavement cold repair material that can quickly open traffic and preparation method thereof

The invention belongs to the technical field of road maintenance repairing and relates to an asphalt pavement cold patching material available for quick opening of traffic and a preparation method thereof; the cold patching material comprises component A, component B and component C; the component A comprises, by weight, 100 parts of limestone mineral material, and 3-5 parts of cement; the component B comprises, by weight, 100 parts of emulsified asphalt, and 40-60 parts of self-emulsified waterborne epoxy resin; the component C comprises, by weight, 100 parts of waterborne epoxy curing agent, and 30-50 parts of an accelerant. Compared with the prior art, the asphalt pavement cold patching material and the preparation method thereof have the advantages that early strength of waterborne epoxy-modified emulsified asphalt mixture can be improved to shorten the time to open the traffic; the material has good water solubility, the preparation process is simple, the preparation conditions are mild, construction is convenient and quick, skilled personnel and special equipment are not required, the material has good low-temperature operability and workability, and is free of volatile solvents, friendly to the construction environment, capable of patching a pavement quickly and good for environmental protection.

Owner:山西省交通科技研发有限公司

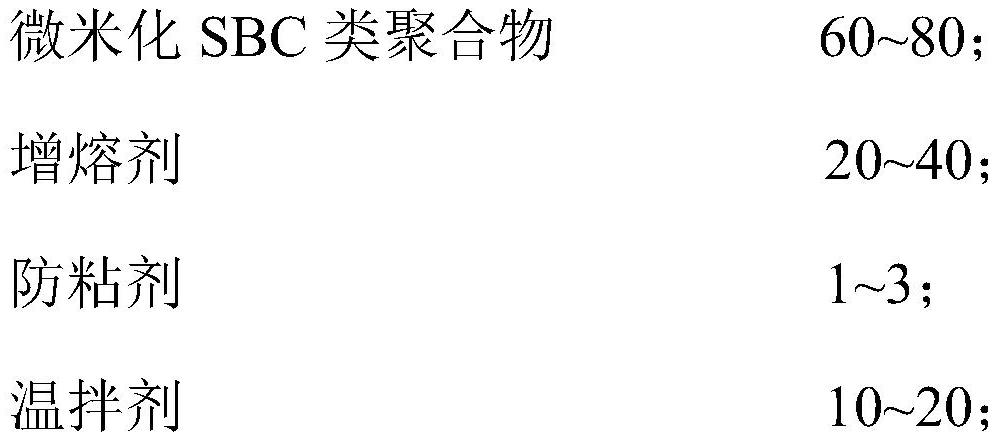

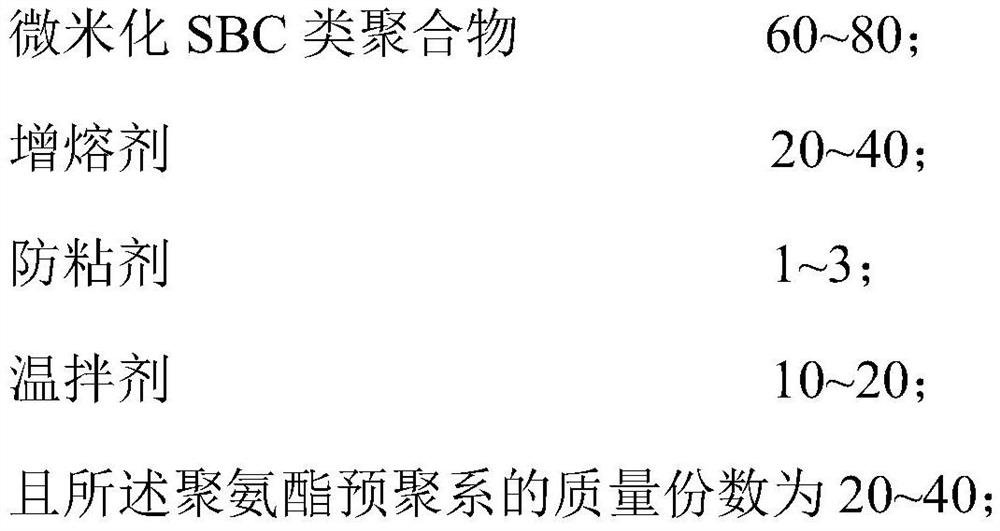

Asphalt modifier for reactive semi-flexible pavement as well as preparation method and application of asphalt modifier

ActiveCN114686007AEasy to prepareEasy to useIn situ pavingsClimate change adaptationDry mixingRoad surface

The invention discloses a reactive asphalt modifier for a semi-flexible pavement and a preparation method of the reactive asphalt modifier. The reactive asphalt modifier comprises a micron SBC mixture and a polyurethane pre-polymerization system which are in non-contact and are respectively stored. The asphalt modifier can be directly and externally added into an asphalt mixing station for dry mixing to realize modification, is convenient to use, can be added at any time, is simple in preparation method and is suitable for large-scale popularization and application. The asphalt modifier provided by the invention can be applied to preparation of a macroporous asphalt mixture, and is further used for preparing a semi-flexible pavement. The asphalt modifier not only can avoid the particle falling phenomenon of the semi-flexible macroporous pavement in the slurry pushing process, but also can reduce the mixing temperature of the mixture and reduce harmful gas emission and environmental pollution. The asphalt modifier forms a reinforcing and toughening structure through reaction, and can overcome the problem of pavement cracking caused by weak cement-asphalt interface to a certain extent; in addition, early strength can be improved, so that road traffic opening time is shortened.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

A kind of environment-friendly anti-slip ultra-thin sealing layer material and preparation method thereof

ActiveCN109486421BPrevent infiltrationAvoid damageAntifouling/underwater paintsPaints with biocidesArchitectural engineeringStructural engineering

The invention discloses an environment-friendly anti-skid ultra-thin sealing layer material and a preparation method thereof. The invention solves the problems of water seepage disease, insufficient anti-skid performance, slight pitting and tiny cracks of the asphalt pavement, and provides a stable and durable sealing layer to protect the asphalt pavement, which can lock the aggregate of the original asphalt pavement, repair poor oil, and facilitate construction. The open traffic time is short, the impact on traffic is small, and it has great technical and social significance. The preventive maintenance process of the present invention can not only maintain the service level of the road surface and delay the maintenance time of major and medium repairs, but also save the whole Maintenance costs during the life cycle.

Owner:中山市易路美新材料科技有限公司 +1

A kind of anti-rutting pavement structure and laying method thereof

ActiveCN105672080BGuaranteed functional requirementsPrevent infiltrationIn situ pavingsSanderVisibility

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

High-viscosity super-elastic anti-reflection crack stress absorption layer and construction method thereof

InactiveCN110284392AImprove tensile strengthImprove adhesion and stabilityIn situ pavingsPolymerCrushed stone

The invention discloses a high-viscosity super-elastic anti-reflection crack stress absorption layer and a construction method thereof. The high-viscosity super-elastic anti-reflection crack stress absorption layer sequentially comprises a stress absorption bonding layer, a layer of fiber yarns, a stress absorption bonding layer and a layer of coarse aggregate from top to bottom, wherein the material of the stress absorption bonding layer is polymer high-viscosity asphalt, the material of the fiber yarns is alkali-free jet yarns, the coarse aggregate is crushed stone with a single particle size, the fibers which are evenly distributed and mutually in overlapped joint in a disordered direction in asphalt combining materials which are evenly spread on the upper and lower layers, and the asphalt combining materials form a network winding structure, the unique structure has higher tension and elasticity, the comprehensive mechanical properties such as tensile strength, shear strength, compression resistance, impact resistance and the like of the layer are effectively improved, the bonding force and the stability of an additionally paved pavement and an original pavement are improved, a high absorption and dispersion function for stress is achieved, the occurrence of reflection cracks can be effectively inhibited, and therefore the service life of the road is prolonged.

Owner:广州市交通设计研究院有限公司

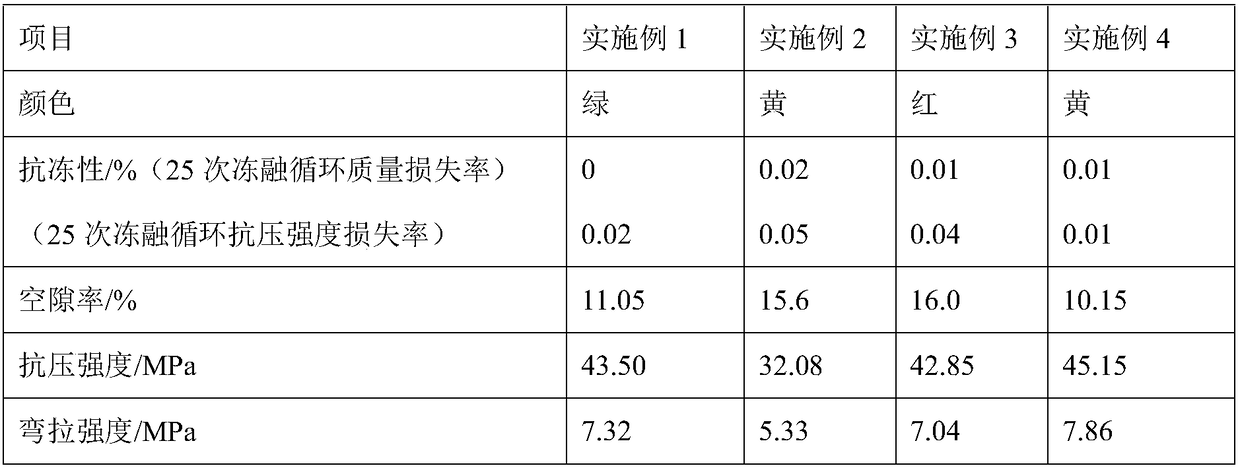

An environmentally friendly freeze-thaw resistant permeable pavement pavement material and preparation method thereof

ActiveCN106495563BReduce pollutionGood energy saving and environmental protection effectFreeze thawingFirming agent

The invention belongs to the technical field of chemical building materials, and particularly relates to an environment-friendly freeze-thaw-resistant permeable pavement material and a preparation method thereof. The pavement material comprises a component A, a component B and a component C; the component A comprises, by mass, 4-6 parts of stones, 3-5 parts of waste concrete particles and 1-2 parts of rubber particles; the component B comprises, by mass, 8.3-9.3 parts of epoxy resin, 1-2 parts of flexibilizer, 0.1 part of thixotropic agent, 0.1 part of dispersing agent, 0.1 part of antifoaming agent, 0.2 part of pigment, 0.1 part of antioxidant and 0.1 part of antioxidant additive; the component C comprises, by mass, 9.8 parts of curing agent, 0.1 part of curing accelerator and 0.1 part of coupling reagent. Compared with the prior art, the material has the advantages of environmental protection, high strength, freeze-thaw resistance, good durability, skid resistance, noise reduction, shock absorption, bright color, difficulty in fading, convenience in construction, short open traffic time.

Owner:SHANXI PROVINCIAL RES INST OF COMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com