Colored pervious concrete and preparation process thereof

A permeable concrete and colored technology, applied in the field of permeable concrete, can solve the problems affecting engineering and opening traffic time, high compressive strength and flexural strength, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

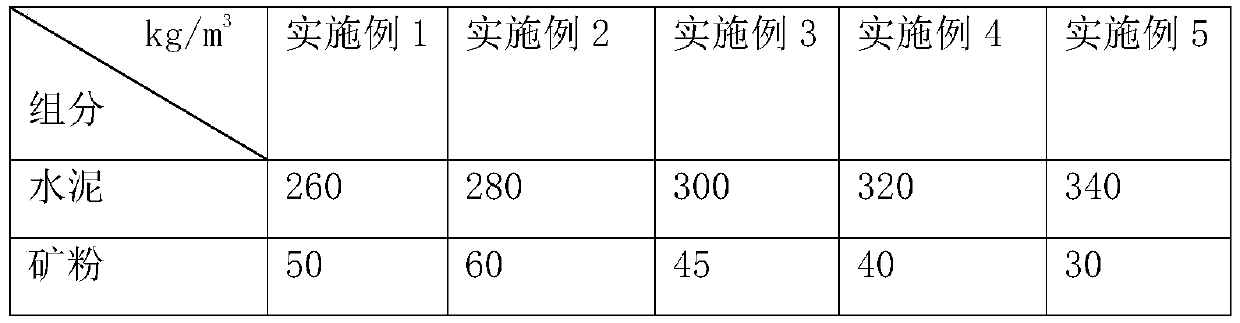

Examples

preparation example 1-3

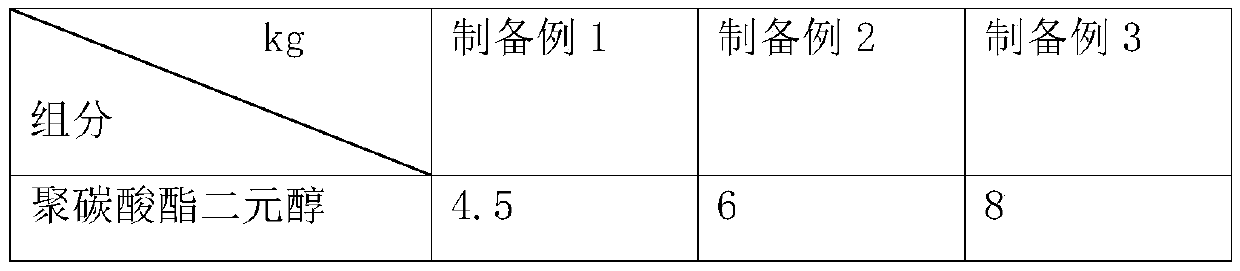

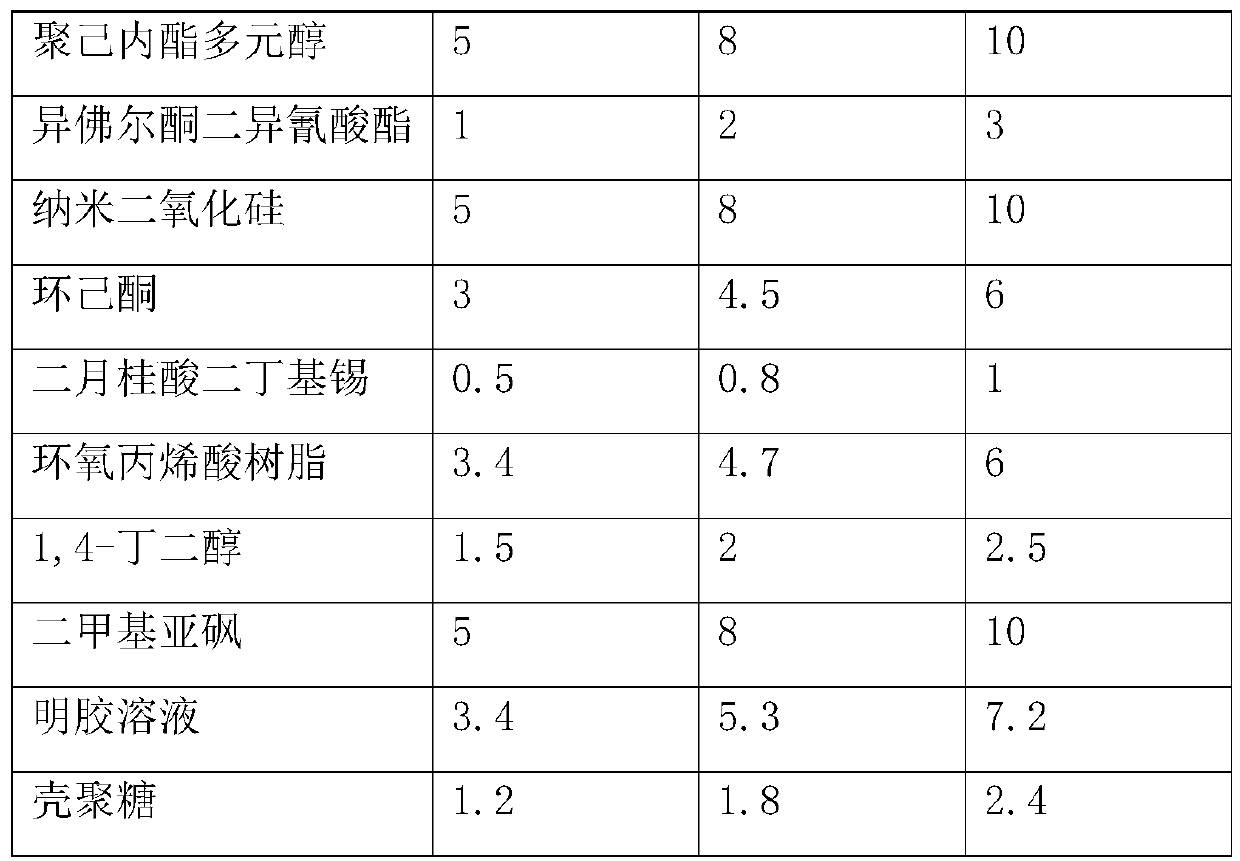

[0046] In Preparation Example 1-3, the polycarbonate diols were selected from the polycarbonate diols sold by Jining Huakai Resin Co., Ltd. with the model number T-5652N, and the polycaprolactone polyols were selected from Dongguan Kaisili Plastics Co., Ltd. The brand of polycaprolactone polyol sold by Raw Material Co., Ltd. is PCL208, the nano-silica is selected from the nano-silica of the model TSP-H10 sold by Jiangsu Tianxing New Material Co., Ltd., and the chitosan is selected from Shanghai Kuoquan Chitosan is sold by Biotechnology Co., Ltd. under Cat. No. 001.

preparation example 1

[0047] Preparation Example 1: (1) According to the ratio of raw materials in Table 1, 4.5kg of polycarbonate diol and 5kg of polycaprolactone polyol were placed in a vacuum drying oven and dried at 100°C for 4 hours; (2) adding 1kg isophorone diisocyanate, 5kg nano silicon dioxide and 3kg cyclohexanone, stir and heat up to 60°C, add 0.5kg dibutyltin dilaurate, heat up to 70°C, stir for 3h, add 3.4kg epoxy acrylic resin and 1.5kg 1,4-butanediol, continue to stir and react for 1h, and keep warm for 2h; (3) add 5kg dimethyl sulfoxide, 3.4kg gelatin solution and 1.2kg chitosan, and stir for 3.5h at 60°C, Prepare polyurethane modified gelatin.

[0048] The raw material ratio of polyurethane modified gelatin in table 1 preparation example 1-3

[0049]

[0050]

preparation example 2

[0051] Preparation Example 2: (1) According to the raw material ratio in Table 1, put 6 kg of polycarbonate diol and 8 kg of polycaprolactone polyol in a vacuum drying oven, and dry at 110 ° C for 2.5 hours; (2) add 2kg isophorone diisocyanate, 8kg nano silicon dioxide and 4.5kg cyclohexanone, stir and heat up to 65°C, add 0.8kg dibutyltin dilaurate, heat up to 75°C, stir for 2h, add 4.7kg epoxy acrylic acid Resin and 2kg 1,4-butanediol, continue to stir and react for 1.5h, keep warm for 2h; (3) add 8kg dimethyl sulfoxide, 5.3kg gelatin solution and 1.8kg chitosan, at 70 ℃, stir for 2h, Prepare polyurethane modified gelatin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com