A kind of preparation method of high-strength cold paved asphalt mixture

A technology of cold-laying asphalt and mixture, which is applied to building insulation materials, building components, buildings, etc., which can solve the problems of slow strength formation rate, complicated preparation process, and low strength, and improve the early strength formation speed and road performance. Excellent, high molding strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0027] Specific Examples The preparation method of room temperature modified asphalt is:

[0028] Step 1: Heat Shell A-grade 70# asphalt to 130 ℃, stir at 500 r / min, and add reactive diluent at the same time, stir for 15-30 minutes until the asphalt is evenly mixed with it;

[0029] Step 2: Add the asphalt flame retardant and modifier to the mixed solution prepared in Step 1 at 100°C according to the ratio, stir and shear at a speed of 3000 r / min to a uniform state without particles, and continue stirring for 10 ~20min;

[0030] Step 3: Add the diluent to the mixed solution prepared in Step 2 at 90°C, stir at a speed of 1000r / min to a uniform state, continue stirring for 10-20 minutes, and store in a sealed container.

[0031] Specific Examples The preparation method of room temperature modified asphalt mixture is:

[0032] Step 1: Pour the aggregate and room temperature modified asphalt into the mixing pot to spread the room temperature modified asphalt evenly on the surface of the ag...

Embodiment 1

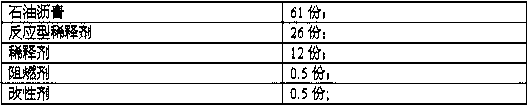

[0040] The room temperature modified asphalt is composed of the following raw materials by weight:

[0041]

[0042] In this embodiment, the reactive diluent is plant polyol, the diluent is n-heptane, the flame retardant is DS-ZR asphalt flame retardant, and the modifier is styrene-butadiene-styrene block copolymer . In this example and the following examples, the petroleum pitch is Shell A grade 70# pitch.

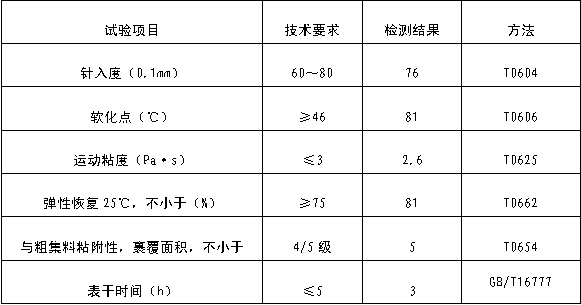

[0043] The test results of various indexes of the normal temperature modified asphalt prepared in Example 1 are as follows.

[0044]

[0045] The proportions of the raw material components of the room temperature modified asphalt mixture in parts by weight are as follows:

[0046] 4.7 parts of room temperature modified asphalt;

[0047] 94.5 parts of aggregate and mineral powder;

[0048] Highly active direct throw strength adjustment additive 0.8 parts.

[0049] The ratio of the room temperature modified asphalt and the strength adjustment additive is determined so that the number...

Embodiment 2

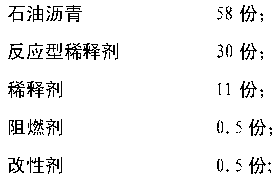

[0055] The room temperature modified asphalt is composed of the following raw materials by weight:

[0056]

[0057] In this embodiment, the reactive diluent is 1,2-butanediol, the diluent is tetrahydrofuran, the flame retardant is DS-ZR asphalt flame retardant, and the modifier is styrene butadiene rubber.

[0058] The test results of various indexes of the normal temperature modified asphalt prepared in Example 2 are as follows.

[0059]

[0060] The proportions of the raw material components of the room temperature modified asphalt mixture in parts by weight are as follows:

[0061] 4.8 parts of room temperature modified asphalt;

[0062] 94.5 parts of aggregate and mineral powder;

[0063] Highly active direct throw type strength adjusting additive 0.7 parts.

[0064] The performance of the mixture formed by mixing the liquid asphalt prepared according to Example 2 and AC-13 type aggregate (according to the above-mentioned weight ratio) is as follows.

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com