Bamboo sleeper assembled to be formed and preparation method thereof

A technology of sleeper, curing and molding, applied in new materials for urban rail transit and railway field, can solve the problems of high brittleness, difficulty in recycling, large weight, etc., and achieve the effect of moderate elastic modulus, expanding application scope and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 (take a 2000mm long, 200mm wide, 160mm thick multi-piece bamboo board assembled sleeper as an example)

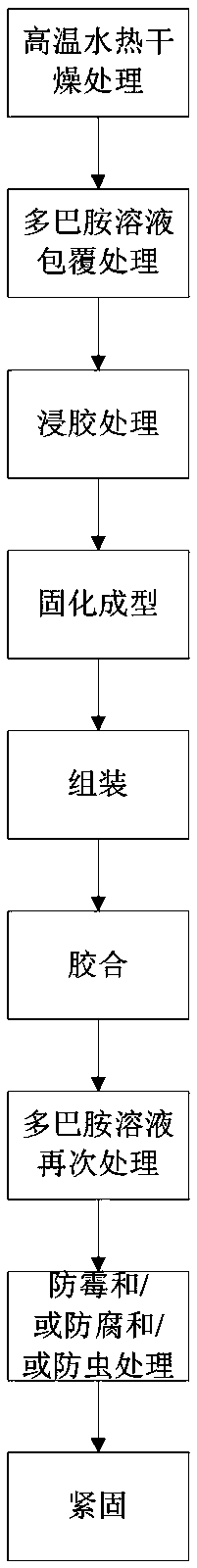

[0046] Such as figure 1 Described, a kind of preparation method of the assembled bamboo sleeper of the present embodiment, comprises the following steps:

[0047] (1) Select 4-year-old Moso bamboo, cut it off, and each section is 1900mm±10mm to obtain round bamboo sections.

[0048] (2) Break the bamboo round sections into bamboo units, remove 100% of the bamboo green and bamboo yellow, cook with ammonia water at a pH of 8.5 for 30 minutes, and then break them into filamentous bamboo units.

[0049] (3) The filamentary bamboo unit is dried and multi-effected under superheated steam with a superheated degree of 30 degrees at 150°C until the moisture content is about 15%, and the filamentous bamboo unit after drying and hydrothermal treatment is obtained.

[0050] (4) Spray 0.05 mg / mL dopamine solution (adding Tris buffer to adjust the pH to 8) on the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com