High initial strength reaction type polyurethane hot melt adhesive and preparation method thereof

A technology of polyurethane hot melt adhesive and initial strength, which is applied in the direction of adhesives, polymer adhesive additives, non-polymer organic compound adhesives, etc. components and other issues, to achieve the effect of easy procurement, easy industrial production, and high initial strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

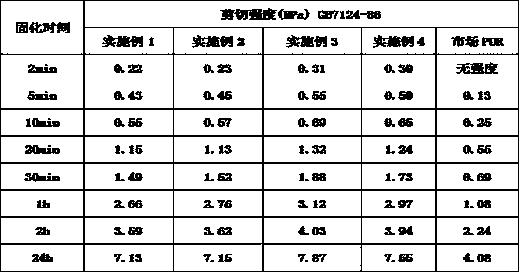

Examples

Embodiment 1

[0029] The high initial strength reactive polyurethane hot-melt adhesive of the present embodiment is made up of the raw material of following parts by weight:

[0030] 60 parts of polyols with a number average molecular weight of 20,000 prepared by condensation of adipic acid and ethylene glycol

[0031] Tackifying resin petroleum resin 40 parts

[0032] Isocyanate compound diphenylmethane-4,4'-diisocyanate 10 parts

[0033] Catalyst dibutyltin dilaurate 0.1 parts

[0034] Adhesion promoter methacryloxypropyl siloxane 0.1 parts

[0035] The preparation method of the high initial strength reactive polyurethane hot-melt adhesive of the present embodiment may further comprise the steps:

[0036] Step 1: Add 60 parts by weight of a polyol with a number average molecular weight of 20,000 and 5 parts by weight of a tackifying resin petroleum resin prepared by condensation of adipic acid and ethylene glycol into the reaction vessel, heat to 80°C, and under vacuum conditions of -0...

Embodiment 2

[0041] The high initial strength reactive polyurethane hot-melt adhesive of the present embodiment is made up of the raw material of following parts by weight:

[0042] Polyether polyol PPG220 25 parts

[0043] Polyester polyol Dynacoll 7360 31 parts

[0044] Epoxy modified polyester polyol 21 parts

[0045] Tackifying resin terpene phenolic modified resin TP-2040 5 parts

[0046] Isocyanate compound 4,4' diphenylmethane diisocyanate 13 parts

[0047] Catalyst dimorpholine diethyl ether 0.2 parts

[0048] Adhesion promoter methacryloxypropyl siloxane 0.5 parts

[0049] The preparation method of the high initial strength reactive polyurethane hot-melt adhesive of the present embodiment may further comprise the steps:

[0050] Step 1, add 25 parts by weight polyether polyol PPG220, 31 parts by weight polyester polyol Dynacoll 7360, 21 parts by weight epoxy modified polyester polyol and 5 parts by weight terpene phenolic modified resin TP-2040, heated to 100°C, melted and d...

Embodiment 3

[0055] The high initial strength reactive polyurethane hot-melt adhesive of the present embodiment is made up of the raw material of following parts by weight:

[0056] Polyether polyol PPG220 20 parts

[0057] Polyester polyol Dynacoll 7360 21 parts

[0058] Acrylic modified polyester polyol 5 parts

[0059] Polyester polyol PH56 25 parts

[0060] Tackifying resin acrylic resin 15 parts

[0061] Isocyanate compound diphenylmethane-2,4'-diisocyanate 15 parts

[0062] Catalyst dibutyltin dilaurate 0.3 parts

[0063] Adhesion promoter methacryloxypropyl siloxane 1 part

[0064] The preparation method of the high initial strength reactive polyurethane hot-melt adhesive of the present embodiment may further comprise the steps:

[0065] Step 1, adding 20 parts by weight polyether polyol PPG220, 21 parts by weight polyester polyol Dynacoll 7360, 5 parts by weight acrylic modified polyester polyol, 25 parts by weight polyester polyol PH56, Heating to 90°C, melting and dehydrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com