Wet curing polyurethane hot melt adhesive for plate material edge sealing

A hot-melt adhesive and moisture-curing technology, which is applied in polyurea/polyurethane coatings, polyester coatings, applications, etc., can solve problems such as limiting the working efficiency of the adhesive process and automatic production, accelerating cooling positioning, and unclear strength, etc., to achieve Improve work efficiency and automation, strong initial adhesion and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

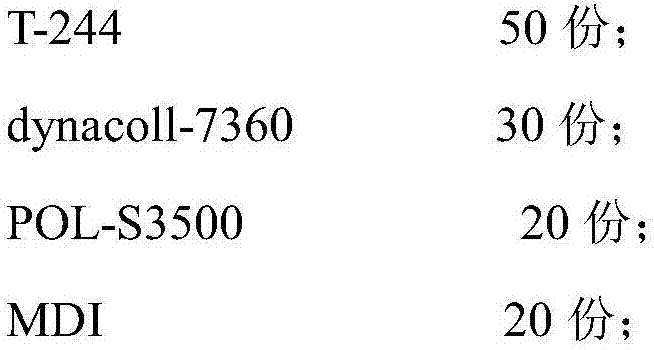

Embodiment 1

[0035]

[0036]

[0037] Initial peel strength: 1.1N / mm; Final peel strength: >2.0N / mm;

[0038] Opening time: 15s; Viscosity / 130°C: 50000cP.

[0039] In this embodiment, the components of the moisture-curing polyurethane hot-melt adhesive have good compatibility, fast positioning, high final peel strength, and good adhesion to the substrate.

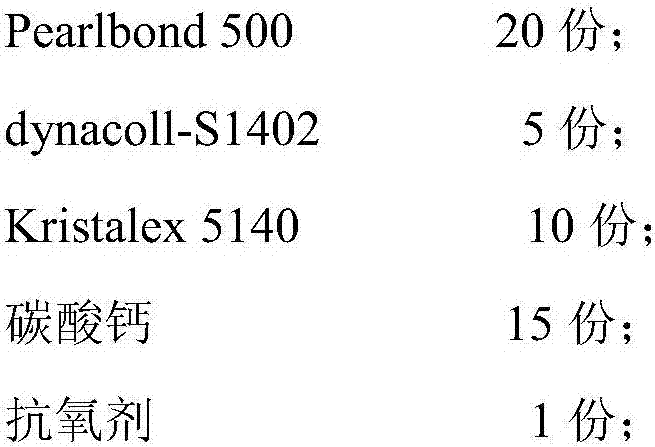

Embodiment 2

[0041]

[0042] Initial peel strength: 1.3N / mm; Final peel strength: >2.0N / mm;

[0043] Opening time: 15s; viscosity / 130°C: 55000cP.

[0044] This embodiment is a preferred embodiment with better effects. Compared with the first embodiment, the moisture-curing polyurethane hot-melt adhesive has better compatibility and initial bonding strength.

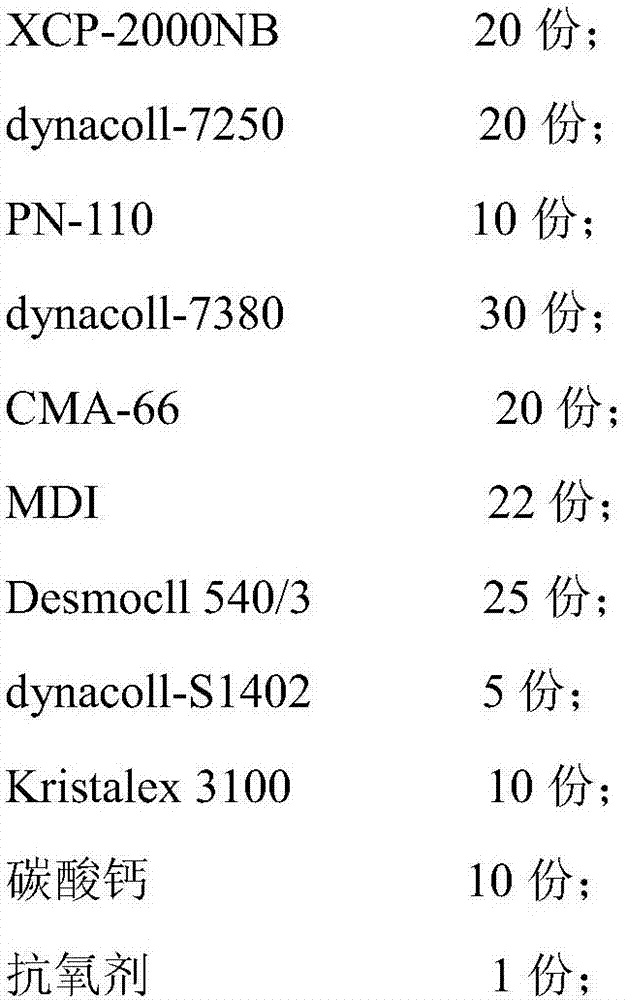

Embodiment 3

[0046]

[0047]

[0048] Initial peel strength: 0.6N / mm; Final peel strength: >2.0N / mm;

[0049] Opening time: 2min; viscosity / 130°C: 65000cP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com