Method for preparing waterborne polyurethane adhesive used for compound soft packaging

A water-based polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as inability to meet, achieve fast drying speed, improve heat resistance, and improve bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

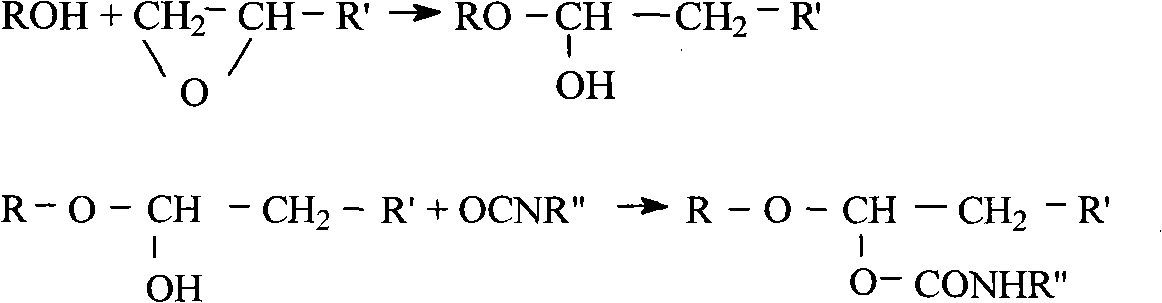

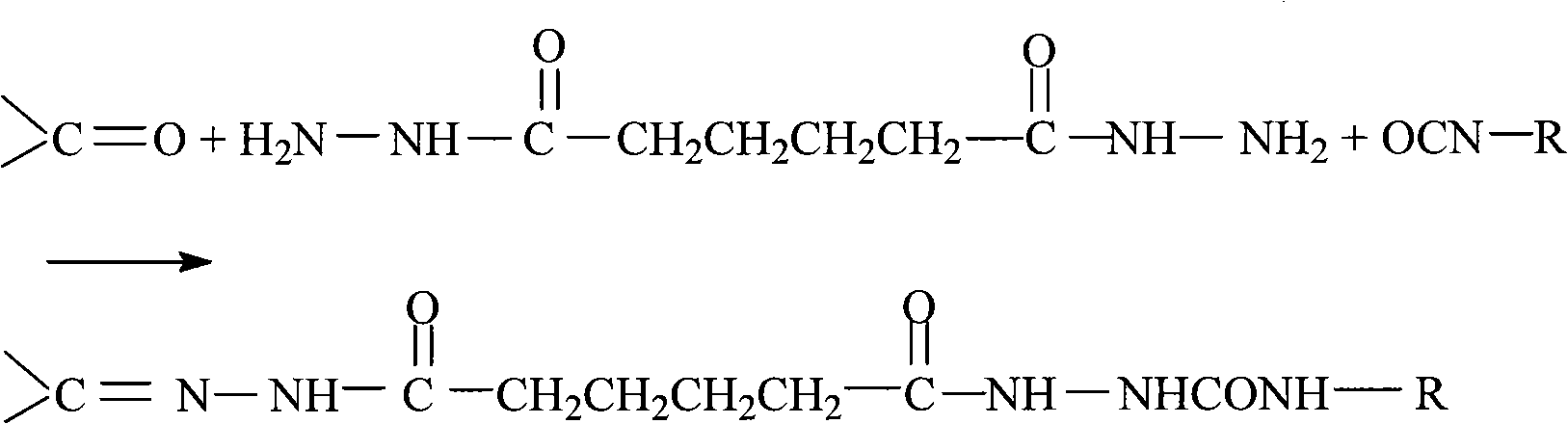

Method used

Image

Examples

Embodiment 1

[0048] (1) Add 100g of toluene diisocyanate and 233g of polycaprolactone diol PCL220N into a four-necked flask equipped with a stirrer, a thermometer, and a reflux condenser device, and react at 80°C for about 2 hours. When the -NCO content of the system reaches 10.66%wt; cool down to 70°C, add 8g 1,4-butanediol, react for 1.5 hours; add 25g epoxy resin (E-44), 25g dimethylolpropionic acid, 8g trimethylolpropane, continue After reacting for 4 hours, add 36g of hydrogenated rosin and stir evenly; cool to 40°C, and neutralize the pH of the system to 7 with triethylamine. Dissolve 2.5g of ethylenediamine in 600ml of water to make a solution, move the above prepolymer to a dispersion device, add the prepared ethylenediamine solution and disperse at a speed of 6000rpm to obtain 1000g of polyurethane emulsion;

[0049] (2) Add 2.0 g of defoamer Foamex830, 5.0 g of wetting agent Wet270, and 5.0 g of adipic hydrazide to the above emulsion, and mix well to obtain a water-based polyuret...

Embodiment 2

[0058] (1) Add 100g of toluene diisocyanate and 225g of polycaprolactone diol PCL220N into a four-necked flask equipped with a stirrer, thermometer, and reflux condenser device, and react at 75°C for about 2.5 hours. When the -NCO content of the system reaches 10.66%wt; cool down to 70°C, add 9.5g 1,4-butanediol, react for 2 hours; add 30g epoxy resin (E-44), 30g dimethylolpropionic acid, 9.5g trimethylolpropane, Continue to react for 5 hours, add 38g of rosin, stir evenly; cool to 40°C, and neutralize the pH of the system to 7 with triethylamine. Dissolve 1.5g of ethylenediamine in 600ml of water to make a solution, move the above prepolymer to a dispersing device, add the prepared ethylenediamine solution and disperse at a speed of 6000rpm to obtain 1000g of polyurethane emulsion;

[0059] (2) Add 1.0 g of defoamer Foamex830, 4.0 g of wetting agent Wet270, and 4.0 g of adipic hydrazide to the above emulsion, and mix well to obtain a water-based polyurethane adhesive.

[006...

Embodiment 3

[0068] (1) Add 100g of toluene diisocyanate and 240g of polycaprolactone diol PCL220N into a four-necked flask equipped with a stirrer, thermometer, and reflux condenser, and react at 80°C for about 2 hours. When the -NCO content of the system reaches 10.66%wt; cool down to 70°C, add 7.5g1,4-butanediol, react for 1 hour; add 18g epoxy resin (E-44), 18g dimethylolpropionic acid, 7.5g trimethylolpropane, Continue to react for 4 hours, add 31g of rosin, stir evenly; cool to 40°C, and neutralize the pH of the system to 7 with triethylamine. Dissolve 4.5g of ethylenediamine in 600ml of water to make a solution, move the above prepolymer to a dispersing device, add the prepared ethylenediamine solution and disperse at a speed of 6000rpm to obtain 1000g of polyurethane emulsion;

[0069] (2) Add 3.0 g of defoamer Foamex830, 6.0 g of wetting agent Wet270, and 6.0 g of adipic hydrazide to the above emulsion, and mix evenly to obtain a water-based polyurethane adhesive.

[0070] The te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com