Polyurethane prepolymer, aquosity polyurethane binder and uses thereof

A polyurethane prepolymer, water-based polyurethane technology, applied in the application of water-based polyurethane adhesives in fields such as shoemaking, water-based polyurethane adhesives and their preparation fields, can solve the problem of low initial tack and adhesion of the adhesive. The problems of high manufacturing cost and high activation temperature of the agent can achieve the effects of excellent weather resistance, water resistance and solvent resistance, fast drying speed and low activation temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0103] In the preparation method of the water-based polyurethane adhesive of the present invention, the reaction of the NCO group and water is suppressed by controlling the temperature when the chain extension reaction is carried out; Compared with water, the active H atom of the chain extender has a relatively higher reaction rate with the NCO group. Therefore, it is ensured that the prepolymer preferentially reacts with the chain extender, and reduces its reaction with water, thereby improving The problem of poor quality of the polyurethane adhesive prepared when the conventional method is used for chain extension is solved, and the cohesive strength of the obtained polyurethane adhesive is improved.

[0104] It can be seen from the above description that the water-based polyurethane adhesive of the present invention is actually an aqueous dispersion of the chain extension product of the polyurethane prepolymer of the present invention. Based on the total weight of the aqueo...

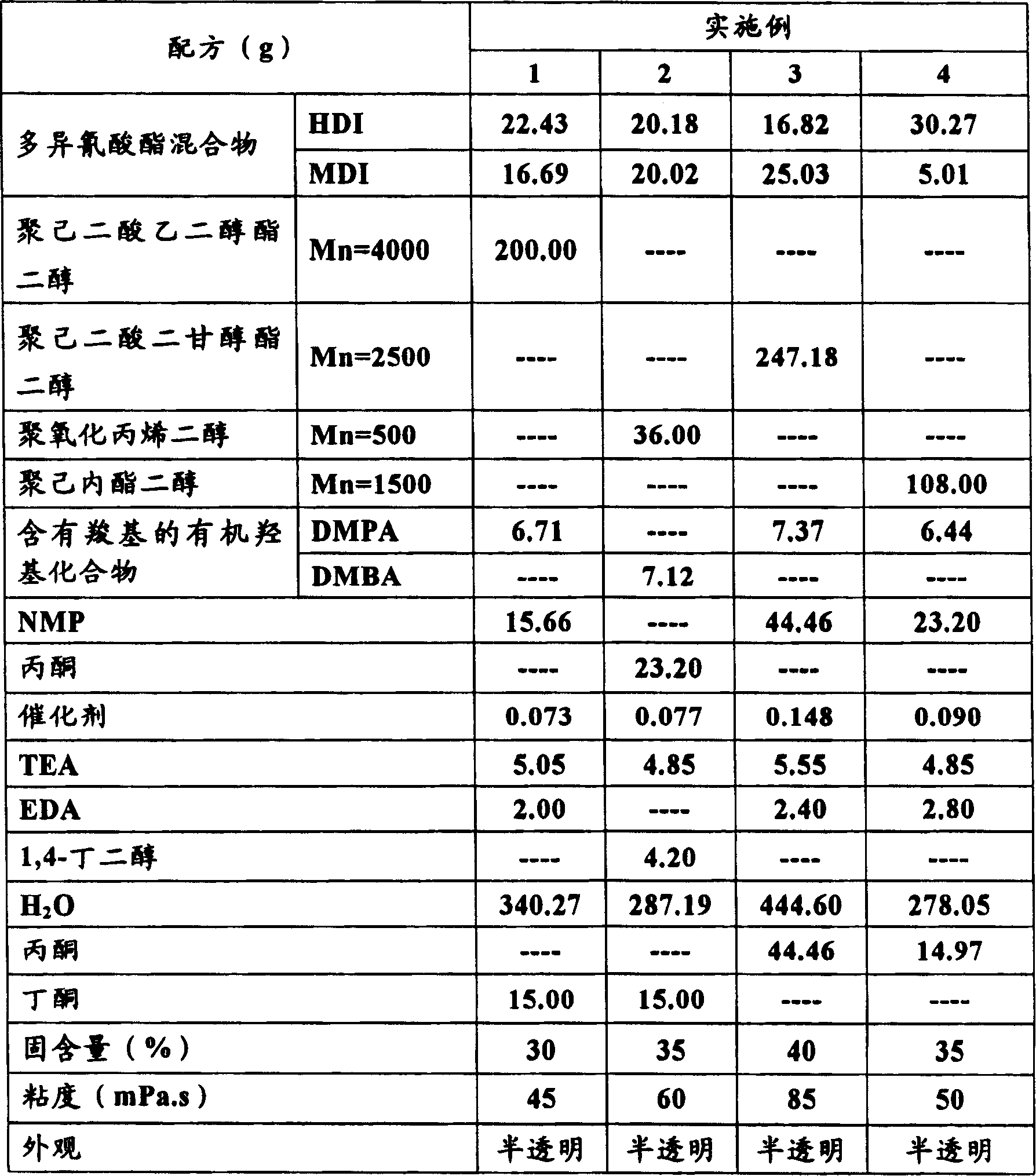

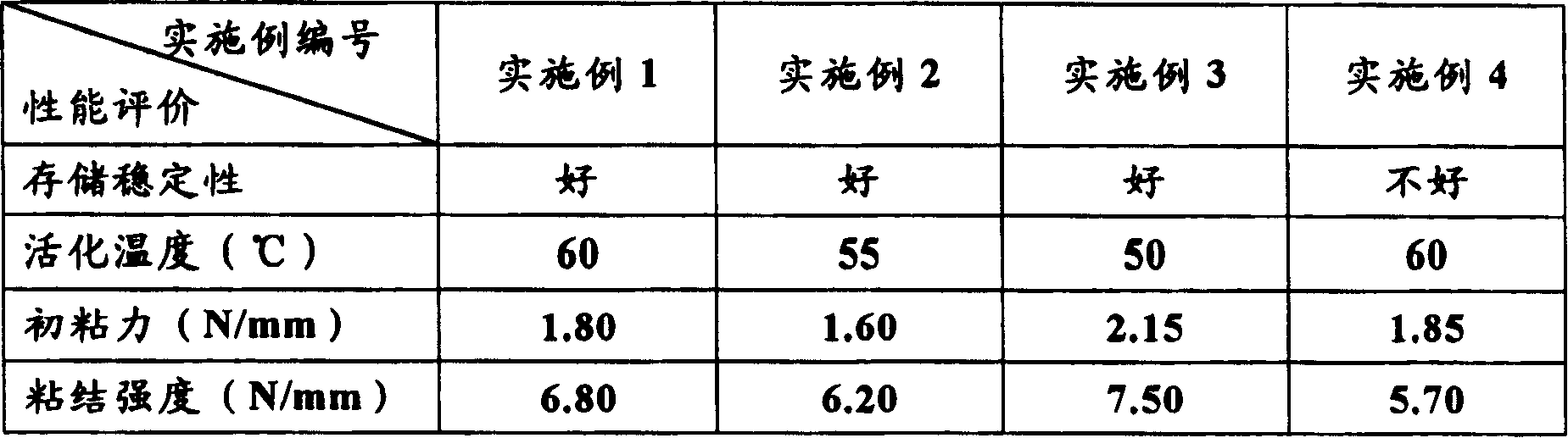

Embodiment 1

[0139] According to the formula in Table 1, polyethylene adipate diol (PEA manufactured by Bayer Company) was placed in a three-necked bottle, treated at -0.08MPa vacuum, 100°C for 3 hours, and cooled to 15°C , slowly add the polyisocyanate mixture under stirring, then add the catalyst, raise the temperature to 70°C, react for 4 hours, cool down to 35°C, add the NMP solution of DMPA, heat up to 70°C, react for 4 hours, cool down to 35°C, put Mix triethylamine and butanone, slowly add the mixture to the above reaction product for neutralization, react for 0.5 hours, quickly disperse the reaction product into deionized water mixed with ethylenediamine, and keep stirring at 0°C in the reaction system and react for 1 hour, and then distill and recover butanone under vacuum condition to obtain the water-based polyurethane adhesive.

[0140] The storage stability, activation temperature, initial tack and cohesive strength of the prepared water-based polyurethane adhesive were measur...

Embodiment 2

[0142] According to the formula in Table 1, polyoxypropylene glycol (PPG manufactured by Jinxi Chemical General Factory) was placed in a three-necked bottle, and was treated at -0.08MPa vacuum degree, 110°C temperature condition for 4 hours, cooled to 20°C, Slowly add polyisocyanate mixture under stirring state, then add catalyst, heat up to 68°C, react for 2 hours, cool down to 35°C, add DMBA acetone solution, heat up to 68°C, react for 5 hours, cool down to 35°C, and triethyl Mix the amine and butanone, slowly add the mixture to the above reaction product for neutralization, react for 0.5 hours, quickly disperse the reaction product in deionized water, stir for 1 hour, then add dropwise 1,4-butanediol, in The reaction system is stirred and reacted at 0° C. for 1 hour, and distilled to recover methyl ethyl ketone and acetone under vacuum conditions to obtain a water-based polyurethane adhesive.

[0143] The storage stability, activation temperature, initial tack and cohesive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com