Enhanced multifunctional surface sizing assistant for papermaking and preparation method thereof

An enhanced, multi-functional technology, applied in papermaking, textiles, papermaking, paper coatings, etc., can solve rare problems and achieve the effects of improving ring compressive strength, good reinforcement performance, and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

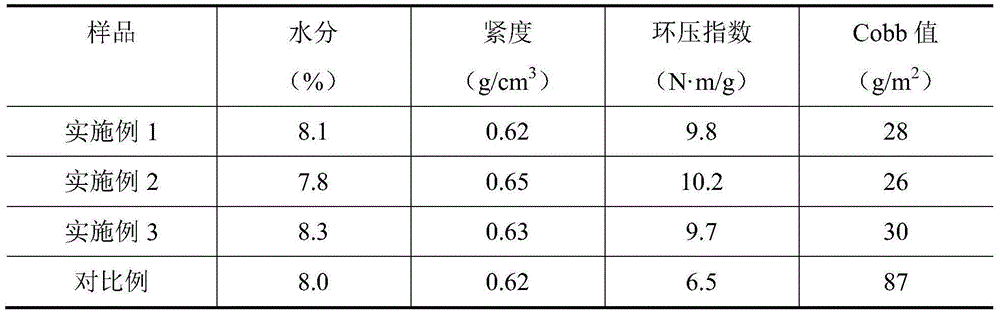

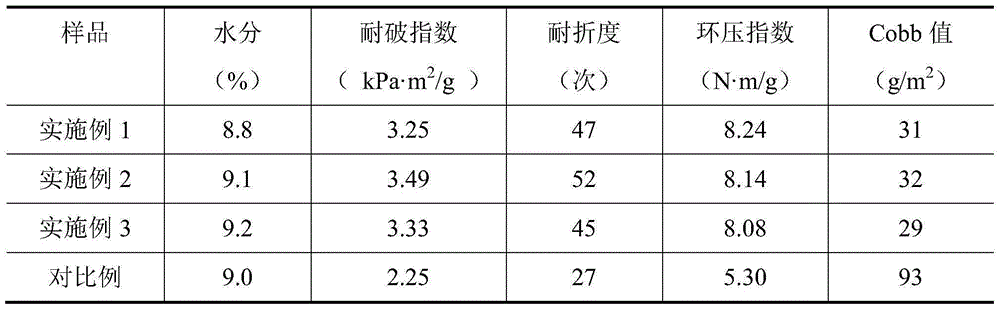

Examples

Embodiment 1

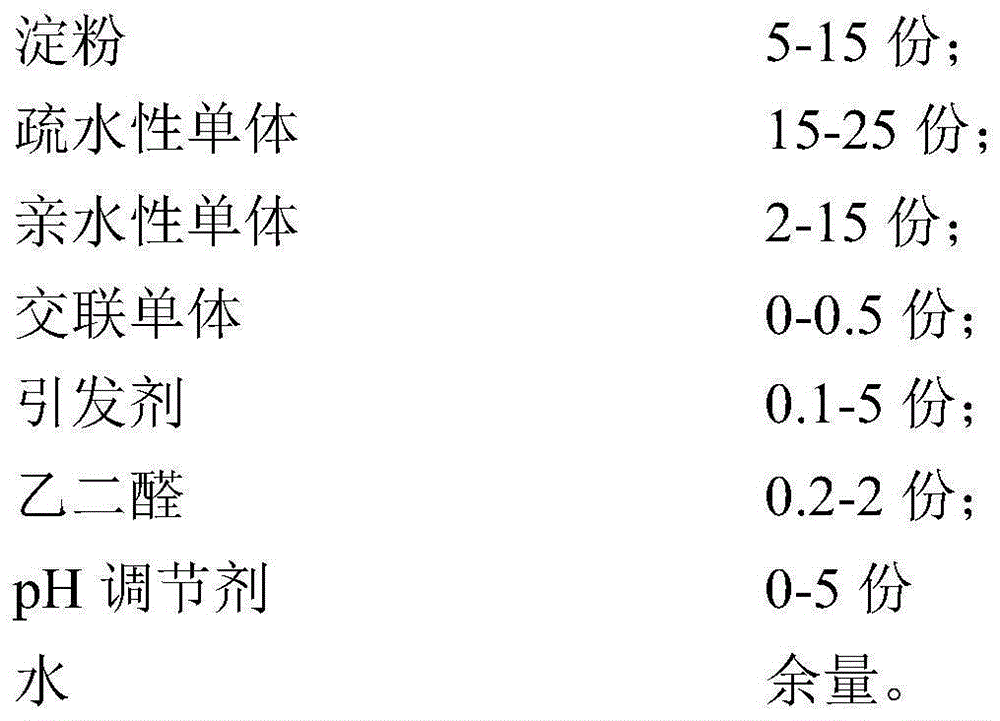

[0027] Taking 1000g as an example, the main raw materials and proportions are as follows:

[0028] Monomer mixture A: styrene 180g, acrylonitrile 25g, butyl acrylate 20g, methyl methacrylate 15g, divinylbenzene 0.3g;

[0029] Monomer mixture B: 70g of acrylamide, 15g of dimethylaminoethyl methacrylate, 7g of acrylic acid, and 50g of water;

[0030] Concrete preparation steps are as follows:

[0031] (1), prepare a four-necked flask with condenser, dropping device, stirrer and thermometer, mix starch 60g, glyoxal 5g (mixed with 40wt% aqueous solution) and water 450g, heat up to 85°C, keep warm For 30 minutes, the viscosity of the control system is not higher than 10mPa·s.

[0032] (2), add 0.12g of ferrous sulfate (dissolved in 10g of water), 3g of glacial acetic acid and 15g of 27wt% hydrogen peroxide in the four-neck flask. Among them, ferrous sulfate and hydrogen peroxide constitute the initiator, and glacial acetic acid is used as the pH regulator of the system.

[0033...

Embodiment 2

[0037] Taking 1000g as an example, the main raw materials and proportions are as follows:

[0038] Monomer mixture A: styrene 140g, ethyl acrylate 25g, tert-butyl acrylate 15g, vinyltriisopropoxysilane 5g, acrylic acid 7g;

[0039] Monomer mixture B: 60g of acrylamide, 1g of diallylamine, 100g of water;

[0040] Monomer mixture C: 10 g of acryloyloxyethyl dimethyl benzyl ammonium chloride (78 wt % aqueous solution), 10 g of water.

[0041] Concrete preparation steps are as follows:

[0042] (1), prepare a four-necked flask with a condenser, a dropping device, a stirrer and a thermometer, mix 90g of starch, 0.05g of α-amylase, 10g of glyoxal (prepared as a 40wt% aqueous solution) and 450g of water , raise the temperature to 93-95°C, keep it warm for 15 minutes, and control the viscosity of the system not to be higher than 15mPa·s.

[0043] (2) Add 3 g of glacial acetic acid and 8 g of 27 wt % hydrogen peroxide into the four-necked flask.

[0044] (3) Keeping the temperature...

Embodiment 3

[0048] Taking 1000g as an example, the main raw materials and proportions are as follows:

[0049] Monomer mixture A: styrene 150g, methyl methacrylate 15g, isooctyl acrylate 15g, acrylonitrile 25g, diethylaminoethyl acrylate 5, acrylic acid 7g;

[0050] Concrete preparation steps are as follows:

[0051](1), prepare a four-necked flask with condenser, dropping device, stirrer and thermometer, mix starch 110g, ammonium persulfate 2g, glyoxal 5g (being mixed with 40wt% aqueous solution) and water 550g, heat up To 88 ℃, keep warm for 60 minutes, control the viscosity of the system not higher than 20mPa·s.

[0052] (2), keep the temperature at 90-93°C, dropwise add monomer mixture A and ammonium persulfate 3g (dissolved in 100g water) at the same time, wherein the dropping time of ammonium persulfate is controlled at 4.5 hours, the monomer mixture A Dropping time was controlled at 4 hours.

[0053] (4) After completion of the dropwise addition, keep warm at 84-86° C. and react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com