Epoxy resin composition and flexible copper-clad plate prepared from same

A technology of epoxy resin and brominated epoxy resin, applied in the direction of epoxy resin glue, synthetic resin layered product, adhesive type, etc. , flexibility and peel strength decrease, etc., to achieve the effect of improving flexibility, excellent heat resistance, and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

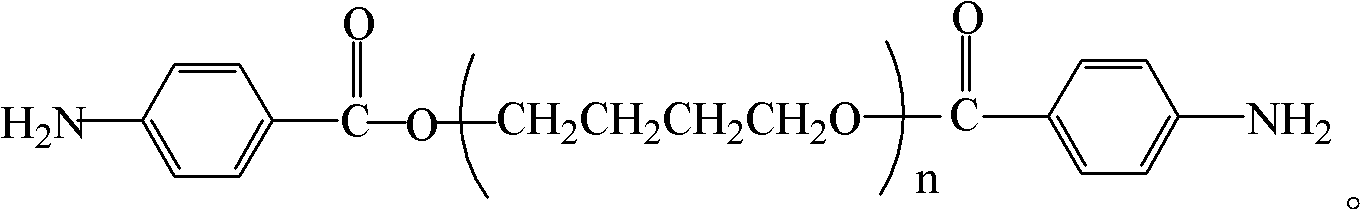

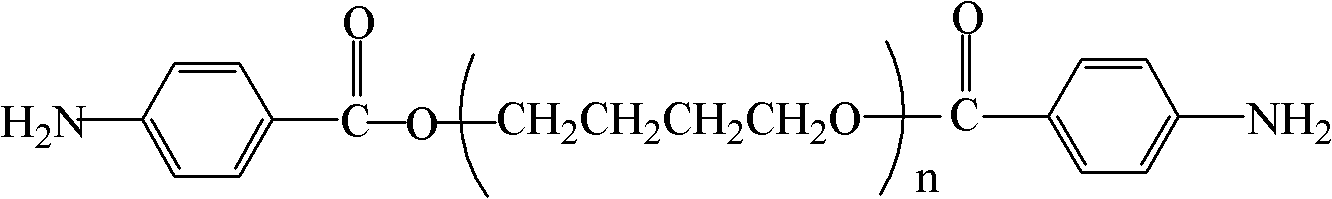

Image

Examples

preparation example Construction

[0054] The above composition is used for the preparation of flexible copper-clad laminates: the liquid dispersion of the composition of the present invention is formed by mixing the required components with an organic solvent, and the dispersion is coated on one or both sides of the poly On the imide film; the polyimide film coated with the dispersion is passed through an online drying oven, heated at 80-160°C for 2 to 8 minutes, thereby removing the organic solvent and drying the composition to form a semi-cured state containing The epoxy resin composition is coated, and then rolled and laminated with copper foil at 70-100°C, and the semi-cured composition is post-cured to obtain the final single-sided or double-sided flexible copper clad laminate. Post curing is preferably carried out at a temperature of 120-160°C.

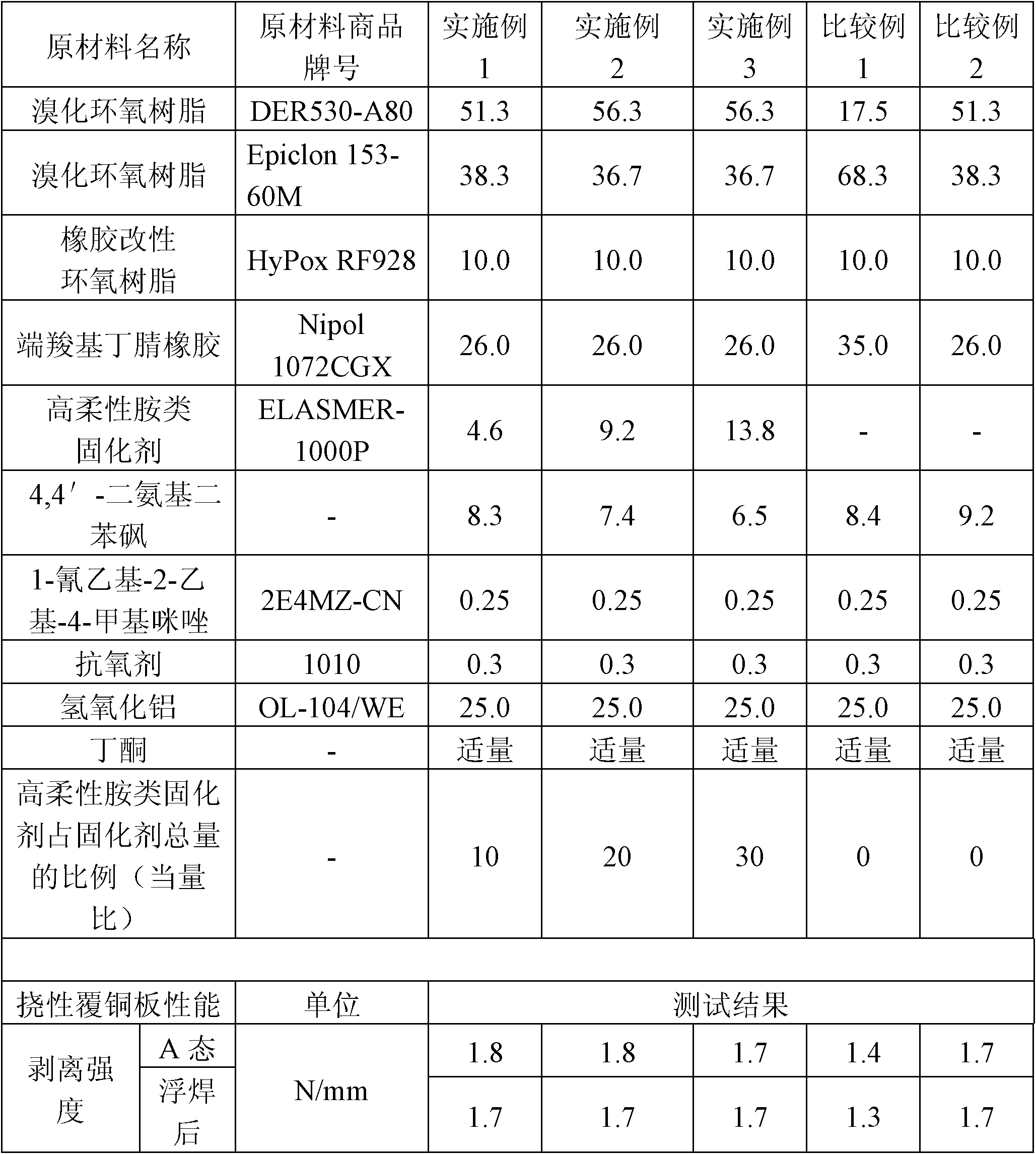

[0055] The heat resistance, flame retardancy, peel strength and folding resistance of the above-mentioned flexible copper clad laminate were measured, and furth...

Embodiment 1

[0058] Brominated epoxy resin (trade name DER530-A80, manufactured by DOW Company, epoxy equivalent 425-440g / eq, solid content 80%) 51.3 parts by weight, brominated epoxy resin (trade name Epiclon153-60M, Dainippon Ink Co., Ltd. Made by the company, epoxy equivalent 390-410g / eq, solid content 60%) 38.3 parts by weight, rubber modified epoxy resin (trade name HyPox RF928, manufactured by U.S. CVC company, epoxy equivalent 200-225g / eq, rubber content 20 %) 10.0 parts by weight, carboxyl-terminated nitrile rubber (trade name Nipol 1072CGX, manufactured by U.S. ZEON company, solid content 100%) 26.0 parts by weight, highly flexible amine curing agent (trade name ELASMER-1000P, Japan Ihara Chemical Industry Co. , LTD.) 4.6 parts by weight, 4,4'diaminodiphenylsulfone 8.3 parts by weight, 1-cyanoethyl-2-ethyl-4-methylimidazole (2E4MZ-CN) 0.25 parts by weight, aluminum hydroxide (trade name OL-104 / WE, manufactured by Albemarle, USA) 25.0 parts by weight; antioxidant (product model 101...

Embodiment 2

[0060] Brominated epoxy resin (trade name DER530-A80, manufactured by DOW Company, epoxy equivalent 425-440g / eq, solid content 80%) 51.3 parts by weight, brominated epoxy resin (trade name Epiclon153-60M, Dainippon Ink Co., Ltd. Made by the company, epoxy equivalent 390-410g / eq, solid content 60%) 38.3 parts by weight, rubber modified epoxy resin (trade name HyPox RF928, manufactured by U.S. CVC company, epoxy equivalent 200-225g / eq, rubber content 20 %) 10.0 parts by weight, carboxyl-terminated nitrile rubber (trade name Nipol 1072CGX, manufactured by U.S. ZEON company, solid content 100%) 26.0 parts by weight, highly flexible amine curing agent (trade name ELASMER-1000P, Japan Ihara Chemical Industry Co. , LTD.) 9.2 parts by weight, 4,4'diaminodiphenylsulfone 7.4 parts by weight, 1-cyanoethyl-2-ethyl-4-methylimidazole (2E4MZ-CN) 0.25 parts by weight, aluminum hydroxide (trade name OL-104 / WE, manufactured by Albemarle, USA) 25.0 parts by weight; antioxidant (product model 101...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com