Forgery-prevention composite cardboard used for packaging cigarettes and processing method thereof

A technology of composite cardboard and processing method, which is applied in the processing field of anti-counterfeiting composite cardboard, can solve the problems of high deformation rate, poor shape stability of cardboard, deformation and bending, etc., achieves good printing performance, overcomes easy imitation and small elastic deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In this embodiment, the composite process is a flow coating composite process, and the key point of the formula in the coating process is to highlight that the security thread on the anti-counterfeiting layer of the composite cardboard will not be covered after coating and printing.

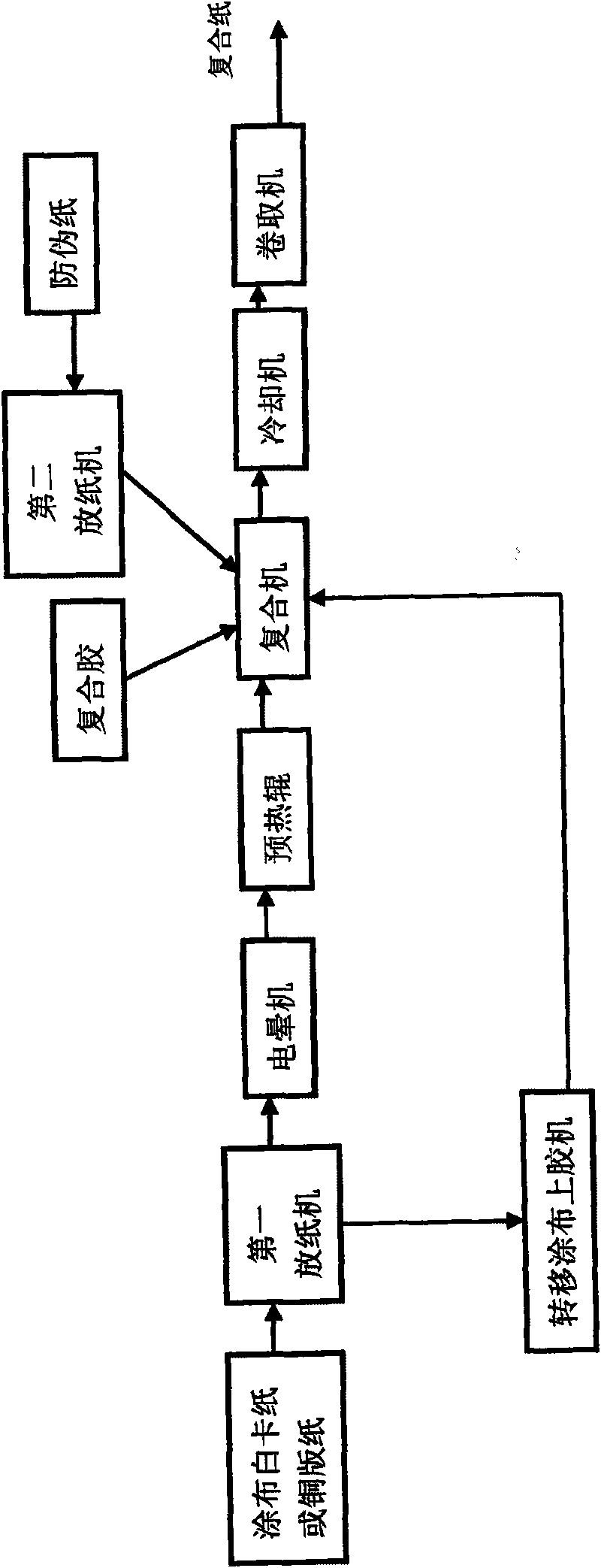

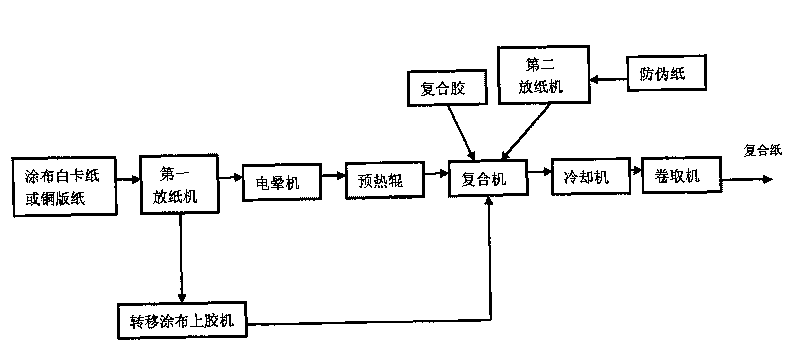

[0050] Composite process, see figure 1 : 150g / m 2 The coated white cardboard or coated paper is loaded into the first paper machine, and its tension is controlled between 3.2 and 6.4N. Here, the tension control should be set in the form of a curve, and automatic closed-loop control. Then the coated white cardboard or coated paper with controlled tension is sent to the corona treatment machine, and the composite surface (uncoated surface or less coated surface) is subjected to corona treatment. The corona voltage is 15-20kV, and the current 10-15A, the treatment here is mainly to make the composite surface have stronger adhesion and performance; then the corona-treated coated white cardboa...

Embodiment 2

[0053] The composite process in this embodiment is a flow coating composite process. The focus of the coating process is to highlight that the watermark on the anti-counterfeit layer of the composite cardboard will not be covered after coating and printing, so that the watermark can be seen on one side.

[0054] The composite cardboard composite process and process are as described in Example 1, and the coating process, equipment and methods used are also as described in Example 1. In order to highlight the effect of single-sided watermarking, the coating layer formula is: polyvinyl alcohol: 10%, methyl cellulose: 20%, methyl butylbenzene-acrylic acid emulsion for papermaking: 15%, superfine calcium carbonate (1000-1200 mesh): 3%, aluminum silver paste: 0.3%, pearl powder: 15%, Dibutanol: 4.7%, water: 32%. The result of adding pearl powder and aluminum silver paste to this formula is to use the reflective effect of the two materials to more clearly highlight the watermark effe...

Embodiment 3

[0056] The composite process in this embodiment is a water-based composite process, and the focus of the coating process is to highlight that the security thread on the anti-counterfeiting layer of the composite cardboard is not covered after coating and printing.

[0057] Composite process, see figure 1 : 170g / m 2 Coated white cardboard or coated paper is placed on the first paper rack, and the tension is controlled at 2.6-3.1N (the tension control here directly affects the flatness of the finished cardboard), and then through the transfer coating glue machine, the The composite surface (uncoated or less coated surface) of coated white cardboard or coated paper under tension control is glued, and the following components (by weight): polyvinyl alcohol 30%, ethylene-vinyl acetate copolymer emulsion 20%, starch 10%, methylcellulose 5%, wetting agent (Tween-7) 5%, water 30%, after mixing evenly, send it to the gluing machine, and the gluing amount is controlled at 12-16g / m 2 ;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com