Biodegradable stone paper and preparation method thereof

A biodegradable and biodegradable resin technology, applied in the field of biodegradable stone paper and its preparation, can solve the problems of pollution, organic matter cannot be recycled, etc., and achieve an easy-to-achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

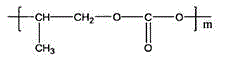

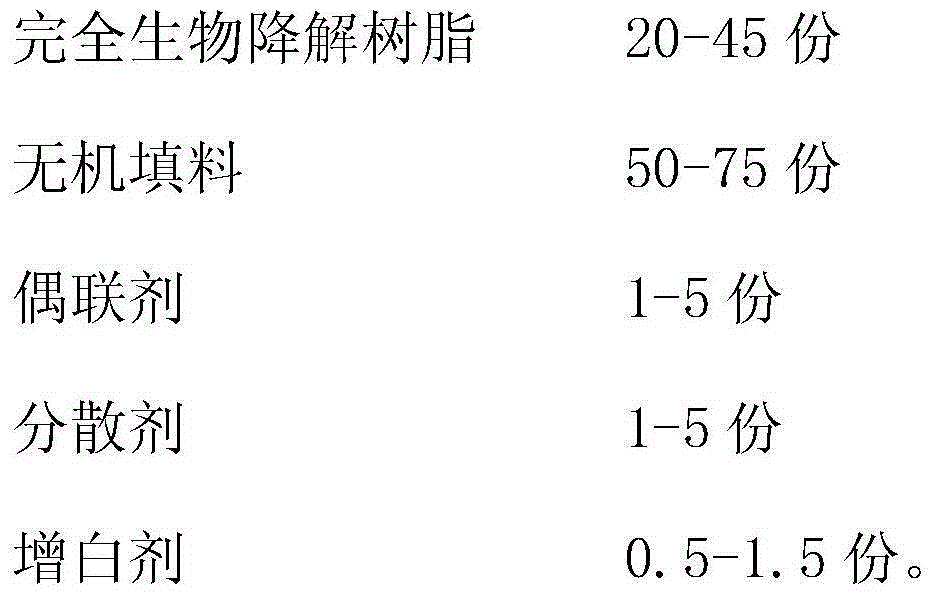

[0034] A biodegradable stone paper consists of the following components by weight:

[0035]

[0036] The fully biodegradable resin is a carbon dioxide-based fully degradable plastic.

[0037] The inorganic filler is montmorillonite, SiO 2 The mixture of calcium carbonate and calcium carbonate has a mass-to-number ratio of 2:1:1.

[0038] The coupling agent is borate.

[0039] The dispersant is sodium stearate and magnesium stearate, and the ratio of parts by mass is 1:1.

[0040] The whitening agent is a mixture of stilbene derivatives, phenylpyrazoline derivatives, benzimidazole derivatives and naphthalimide derivatives, and its mass-number ratio is 1:2:1:3 .

[0041] A method for preparing the above-mentioned biodegradable stone paper, comprising the steps of:

[0042] 1) Put the fully biodegradable resin and inorganic filler in an oven, dry at 20°C, mix and stir evenly, then add coupling agent, dispersant and whitening agent and stir for 30s;

[0043] 2) Add the abov...

Embodiment 2

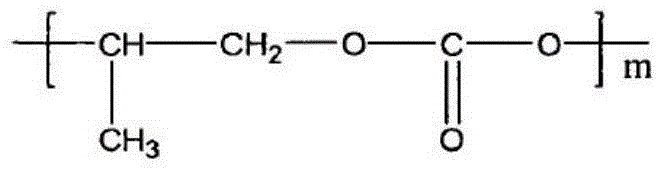

[0046] A biodegradable stone paper consists of the following components by weight:

[0047]

[0048] The fully biodegradable resin is a mixture of carbon dioxide-based fully degradable plastics and biodegradable polyester, with a ratio of parts by mass of 2:1.

[0049] Described biodegradable polyester is the mixture of polylactic acid (PLA), polybutylene succinate (PBS), polyadipate-terephthalate-butylene glycol ester (PBAT), its mass parts The ratio is 2:2:1.

[0050] Described inorganic filler is montmorillonite and SiO 2 mixture, the mass-to-number ratio is 2:1.

[0051] The coupling agent is a mixture of borate ester and siloxane coupling agent, and the ratio of parts by mass is 1:1.

[0052] The dispersant is a mixture of sodium stearate, calcium stearate and magnesium stearate, and the ratio of parts by mass is 3:2:1.

[0053] The whitening agent is a mixture of stilbene derivatives, phenylpyrazoline derivatives, benzimidazole derivatives, phenylpyrazole derivati...

Embodiment 3

[0059] A biodegradable stone paper consists of the following components by weight:

[0060]

[0061] The fully biodegradable resin is a mixture of carbon dioxide-based fully degradable plastics and biodegradable polyester, with a ratio of parts by mass of 2:1.

[0062] The biodegradable polyester is a mixture of polylactic acid (PLA) and poly(adipate-terephthalate-butylene glycol) (PBAT), with a ratio of parts by mass of 1:2.

[0063] The inorganic filler is SiO 2 The mixture of calcium carbonate and calcium carbonate has a mass-to-number ratio of 3:1.

[0064] The coupling agent is borate.

[0065] The dispersant is a mixture of sodium stearate and magnesium stearate, and the ratio of parts by mass is 2:1.

[0066] The whitening agent is a mixture of stilbene derivatives and titanium dioxide, and the ratio of parts by mass is 3:1.

[0067] A method for preparing the above-mentioned biodegradable stone paper, comprising the steps of:

[0068] 1) Put the fully biodegrad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com