Biologically degradable oil well cement fluid loss additive and preparation method thereof

A technology of oil well cement and biodegradation, which is applied in the field of oilfield chemistry and oil and gas well cementing, can solve the problems of poor salt resistance of cement fluid loss reducer, failure to meet deep water surface casing, strong retarding side effects, etc., and achieve broad application range, excellent ability to reduce water loss, retarding side effects and less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

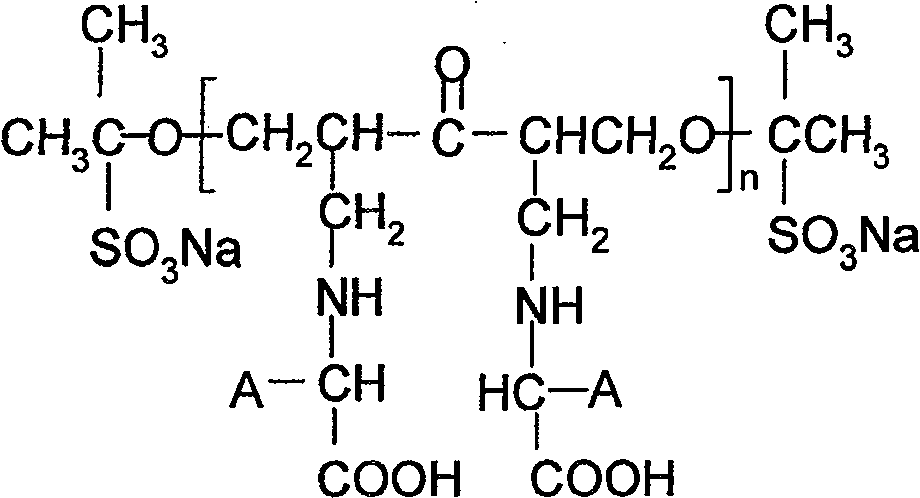

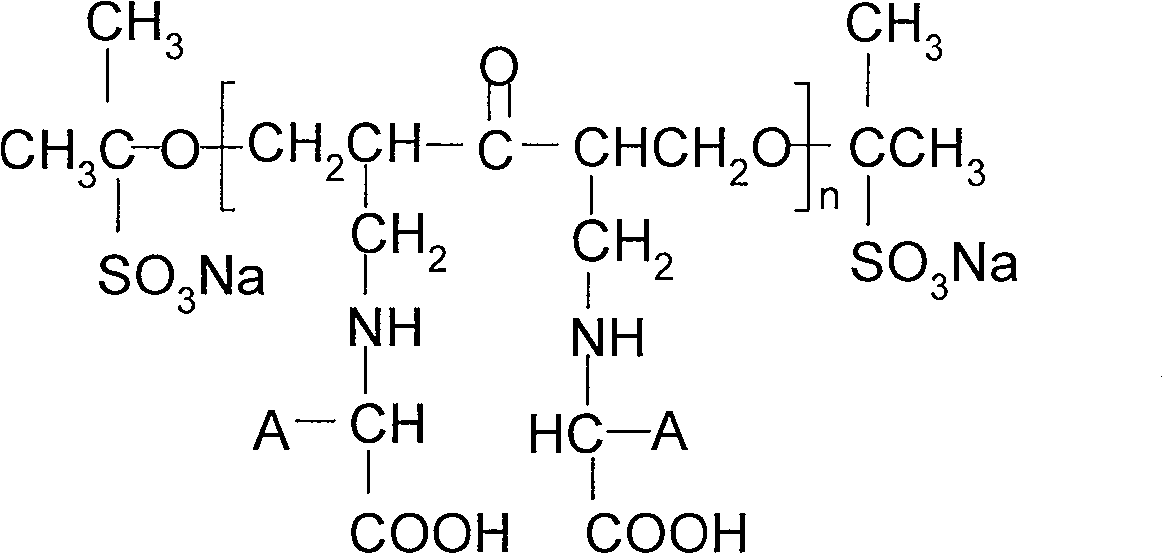

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 illustrates the preparation method of biodegradable oil well cement fluid loss reducer

[0016] I, preparation of hydroxyethyl cellulose. Put 1 part of refined cotton powder (M30, Guangrao Refined Cotton Factory, Shandong Province) with a degree of polymerization of 800 to 1000 in the reaction kettle, add 8 parts of isopropanol solution and 2.54 parts of NaOH, stir at room temperature for 2 hours, and then react The temperature of the solution was raised to 50°C, and 0.6 parts of ethylene oxide was added dropwise within 1.5h, and the reaction temperature was maintained at 60°C for 2 hours to obtain a crude hydroxyethyl cellulose product; the crude product was washed with isopropanol, And use dilute hydrochloric acid solution to neutralize the reaction solution to pH = 6, then add 0.01 part of 30% glyoxal aqueous solution to crosslink at 45 ° C for 2 hours, and finally heat and concentrate the solution to obtain a liquid product with a molar substitution deg...

Embodiment 2

[0019] Example 2, Evaluation of the fluid loss reducing performance of the oil well cement fluid loss reducing agent of the present invention

[0020] Add a certain mass percentage (based on the cement quality) of liquid sample C in Shengwei Oil Well G grade cement, prepare cement slurry with a water-cement ratio of 0.44 according to the GB10238-88 standard, and then press the People's Republic of China Petroleum and Natural Gas Industry Standard SY / T 5960-94 "Evaluation method of oil well cement fluid loss reducer" measures the water loss of sample C, and evaluates the water loss reducer performance of sample C.

[0021] The water loss reduction effect of sample C on oil well cement was evaluated according to the above method, and the results are shown in Table 1. Experimental results show that the fluid loss reducing agent for oil well cement of the present invention not only has good fluid loss reducing performance in the fresh water solution within the range of 25°C to 80...

Embodiment 3

[0024] Example 3, the evaluation of the influence of the oil well cement fluid loss reducer of the present invention on the setting time and compressive strength of cement slurry

[0025] Prepare cement slurry according to GB10238-88 standard, the water-cement ratio is 0.44, sample C is used as fluid loss reducer, and the cement slurry density is 1.91g / cm 3 . The initial setting time, final setting time and compressive strength of the cement slurry were measured, and the evaluation results are shown in Table 2. The experimental results show that the oil well cement fluid loss reducer of the present invention has a certain influence on the setting time and compressive strength of oil well cement in the range of 25°C to 80°C, but the setting time is only extended for about 1 hour, and the compressive strength is only slightly This shows that the retarding side effects of the fluid loss reducer of the present invention are relatively small.

[0026] Table 2

[0027] Sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com