A kind of preparation method of polyacrylate/lignin composite oil-absorbing material

A technology of acrylate and alkyl acrylate, applied in the field of functional polymer synthetic materials, can solve the problems of difficult preparation of high oil-absorbing resin, mutual interference of oil-absorbing performance, poor polymerization ability, etc., achieve good structural uniformity and wide application range , fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

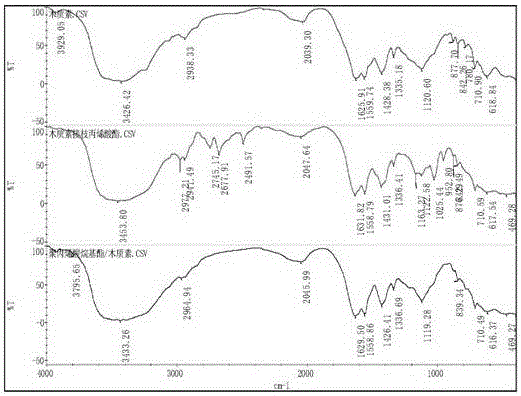

[0018] At 0°C, drop 1wt% triethylamine into the solvent / water mixture solution of 1g lignin, and add an appropriate amount of acryloyl chloride dropwise (the molar ratio of acryloyl chloride to hydroxyl groups in lignin is 2:1) until the system produces the maximum The amount of precipitation was used to complete the reaction, and the lignin acrylate A was obtained by washing three times with absolute ethanol, in which the grafting rate of double bonds was 50.09% (based on lignin hydroxyl content as 100%). Comparison Manual Attached figure 1 Infrared spectra of lignin and lignin acrylate A, analysis of the absorption band of product A at 2400cm-1 to 2900cm-1 is the resonance peak strengthened by the double bond between the benzene ring and the acryloyl group after lignin grafting, proving that the lignin Vegan acrylates have been synthesized.

[0019] Then mix the monomers of A, butyl acrylate and octadecyl acrylate uniformly at a molar ratio of 1:2:1, make a solution of 0.25...

Embodiment 2

[0022] Refer to Example 1 to prepare lignin acrylate A, and then uniformly mix the monomers of A, butyl acrylate and octadecyl acrylate at a molar ratio of 1:3:2, and use deionized water to make 0.25% to 3.0 % (W / V) solution into a 100mL three-necked flask (intermediate indirect reflux condenser), add 3wt% benzoyl peroxide, 7wt% 1,4-butylene dimethacrylate and stir evenly Nitrogen was introduced, and then polymerized at 70° C. for 30 hours. After the polymerization reaction was completed, the freeze-dried product B was washed to obtain polyacrylate / lignin composite oil-absorbing material C (yield 81.5%). The butyl acrylate and stearyl acrylate polymers without lignin acrylate were used as the control sample D to conduct the chloroform adsorption test experiment, and 0.1g of the above-mentioned composite oil-absorbing material C and control sample D were weighed and placed in a 100mL grinding port. Dry the Erlenmeyer flask, add 50mL of distilled water to soak, measure the mass...

Embodiment 3

[0024] Refer to Example 1 to prepare lignin acrylate A, and then uniformly mix the monomers of A, butyl acrylate and octadecyl acrylate at a molar ratio of 1:3:2, and use deionized water to make 0.25% to 3.0 % (W / V) solution was added to a 100mL three-necked flask (intermediate indirect reflux condenser), 3wt% benzoyl peroxide and 7wt% ethylene glycol diacrylate were added and stirred evenly, then nitrogen gas was introduced, and then at 70 Polymerization was carried out at °C for 30 hours. After the polymerization reaction was completed, the freeze-dried product B was washed to obtain polyacrylate / lignin composite oil-absorbing material C (yield 87.88%). The butyl acrylate and stearyl acrylate polymers without lignin acrylate were used as the control sample D to conduct the chloroform adsorption test experiment, and 0.1g of the above-mentioned composite oil-absorbing material C and control sample D were weighed and placed in a 100mL grinding port. Dry the Erlenmeyer flask, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com