High water vapor permeability cast film

A water vapor permeable, cast film technology, applied in the field of high water vapor permeable cast film, can solve the problems of poor water vapor permeability, etc., and achieve the effect of simple and easy preparation method and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

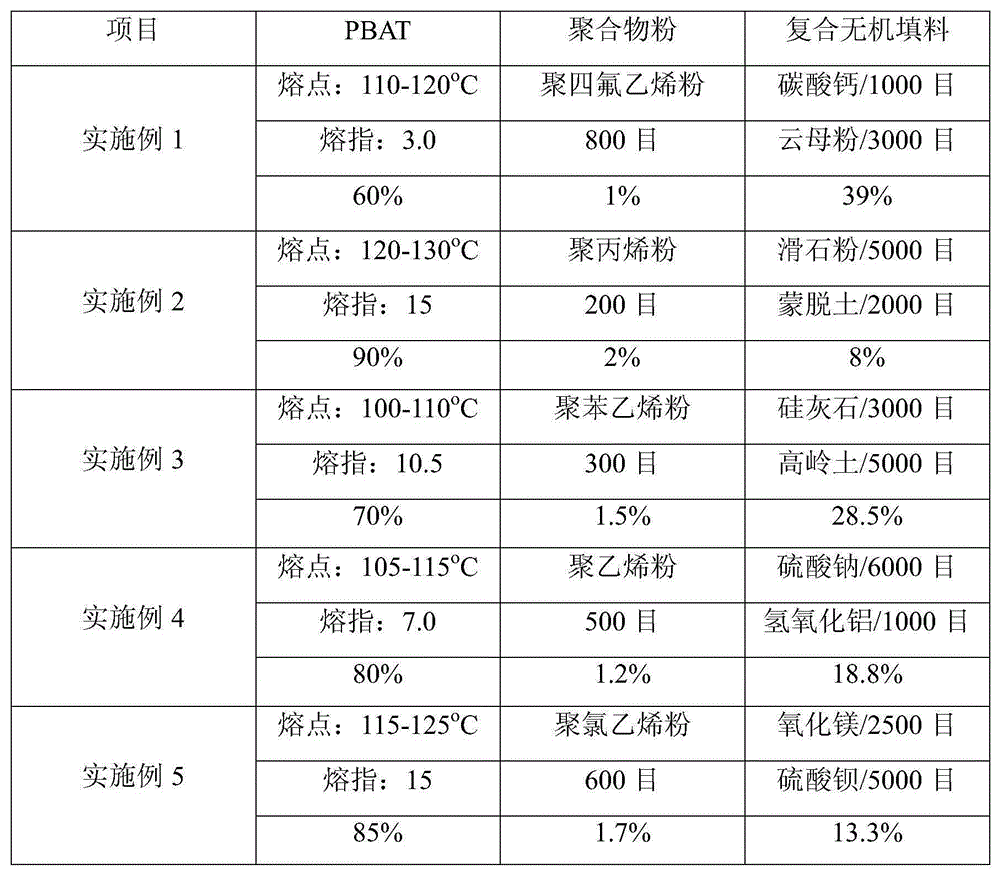

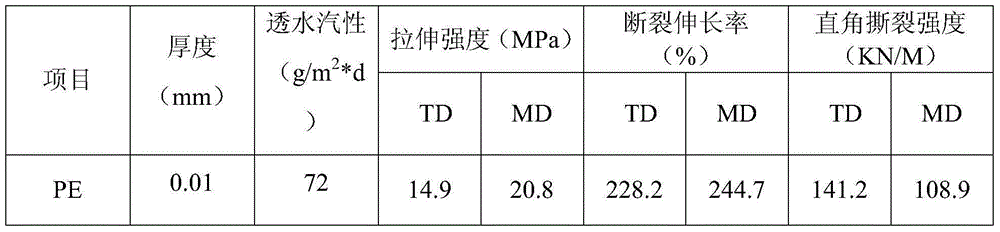

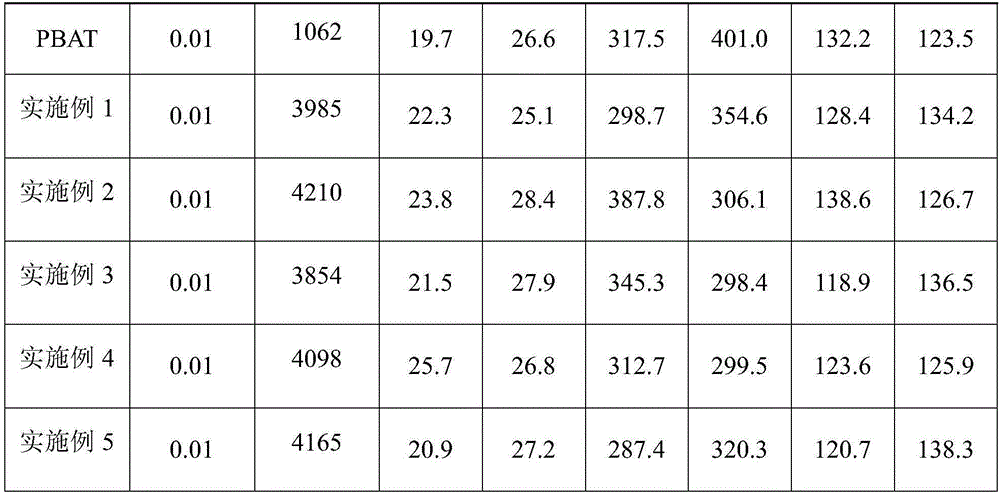

[0021] The present invention is further described below in conjunction with embodiment.

[0022] The preparation of the casting film in the embodiment of the invention is divided into two steps: (1) Material preparation: add each raw material component into a high-speed mixer, mix it evenly and release it, and then add it to a co-rotating parallel twin-screw extruder for co-extrusion A completely biodegradable cast film material is obtained by granulation, and the extrusion temperature is 140-160°C; (2) Cast film preparation: put the cast film material into the PE cast film extruder, flow Film extension, extrusion temperature: 160-180°C, die head temperature: 170-180°C, casting roll and rubber roll temperature: 10-50°C.

[0023] The co-rotating parallel twin-screw extruder used is: the diameter of the screw is 62.5 mm, the ratio of length to diameter is 48:1, and the barrel has 12 heating zones in total. The cast film machine used is a PE cast film extruder: screw diameter 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com