High barrier aluminum-plating composite film for packing liquid dairy product

An aluminized composite film and packaging technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of poor oxygen barrier, easy breakage of aluminum foil, pollution, etc., and achieve high water resistance, high gas barrier, high The effect of folding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

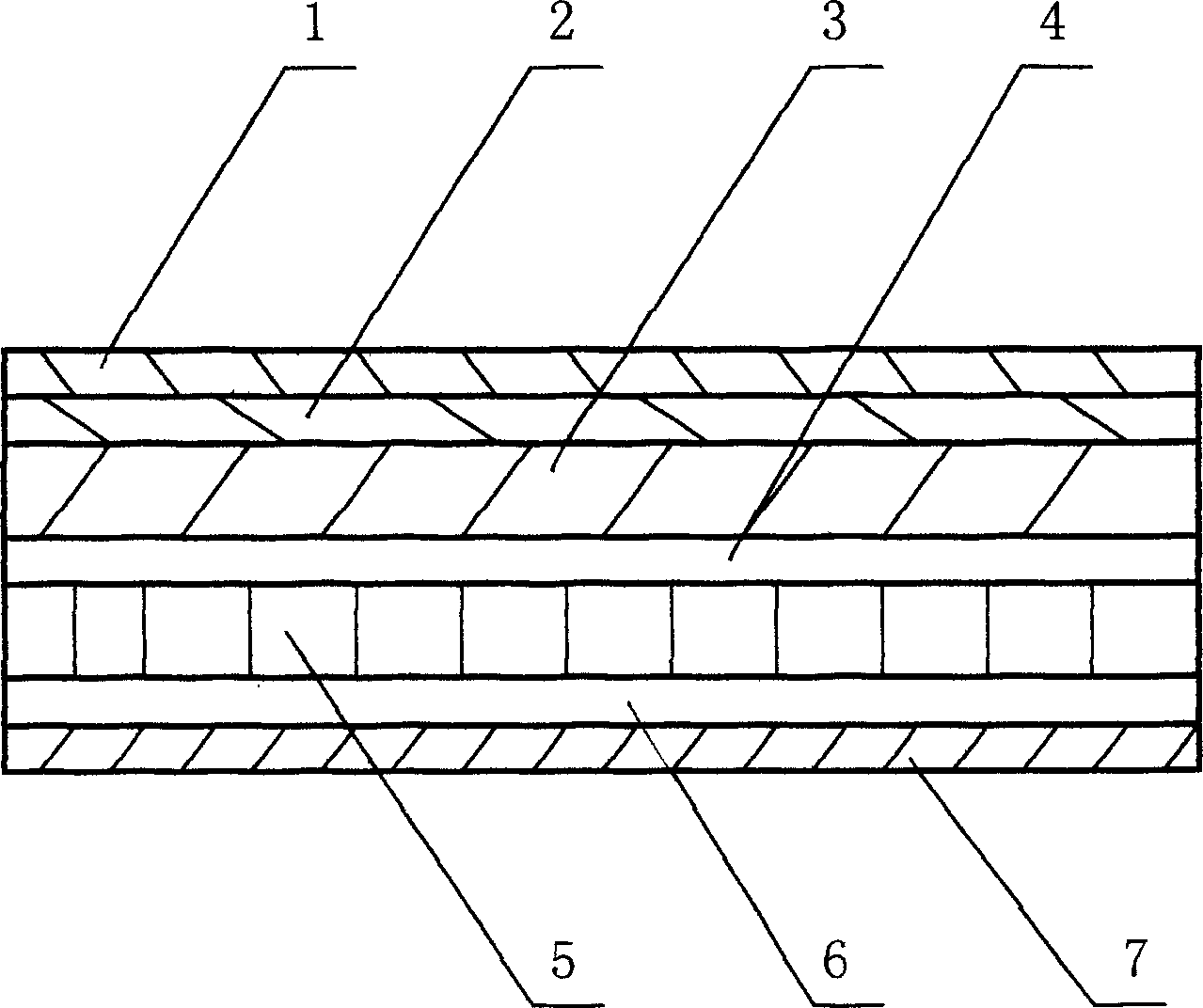

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0009] As shown in the figure, the present invention has a hierarchical structure, and the hierarchical structure is a printable layer 1, an adhesive layer 2, an aluminum layer 3, an adhesive layer 4, a barrier layer 5, an adhesive layer 6 and a thermal layer from outside to inside. Sealing layer 7. The barrier layer 5 is made of polyvinylidene chloride copolymer or ethylene-vinyl alcohol copolymer.

[0010] The material of the printable layer 1 is polyethylene, selected from one of low-density polyethylene, linear low-density polyethylene, medium-density polyethylene, high-density polyethylene, metallocene-catalyzed polyethylene, or low-density polyethylene , linear low density polyethylene, medium density polyethylene, high density polyethylene and a blend of at least two components of metallocene-catalyzed polyethylene.

[0011] The material of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com