Gas barrier laminate

A laminated body and gas barrier technology, applied in coatings, electrical components, layered products, etc., can solve problems that may not be met, and achieve the effect of improving gas barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] A polyvinyl alcohol resin (hereinafter abbreviated as "PVA") having an average degree of polymerization of 2600 and a degree of saponification of 99.5 mol% was dissolved in water to obtain 48% by mass of water-containing PVA. Use an extruder, install a gear pump, make the change of the discharge amount within 2%, and use a T-shaped die with a surface roughness of 0.1s to form the water-containing PVA into a sheet, and stretch at a stretching temperature of 90°C and a stretching ratio of 2.0. Stretch in the longitudinal direction (MD), then stretch in the transverse direction (TD) at a stretching temperature of 110°C and a stretch ratio of 2.0, and perform a heat treatment at 200°C for 5 seconds to obtain biaxial stretching with a thickness of 12 μm PVA film. A mixture of isocyanate compound ["Coronate L" manufactured by Nippon Polyurethane Industry Co., Ltd.] and saturated polyester ["Byron 300" manufactured by Toyobo Co., Ltd.] was coated on one side of the film at a m...

Embodiment 2~20

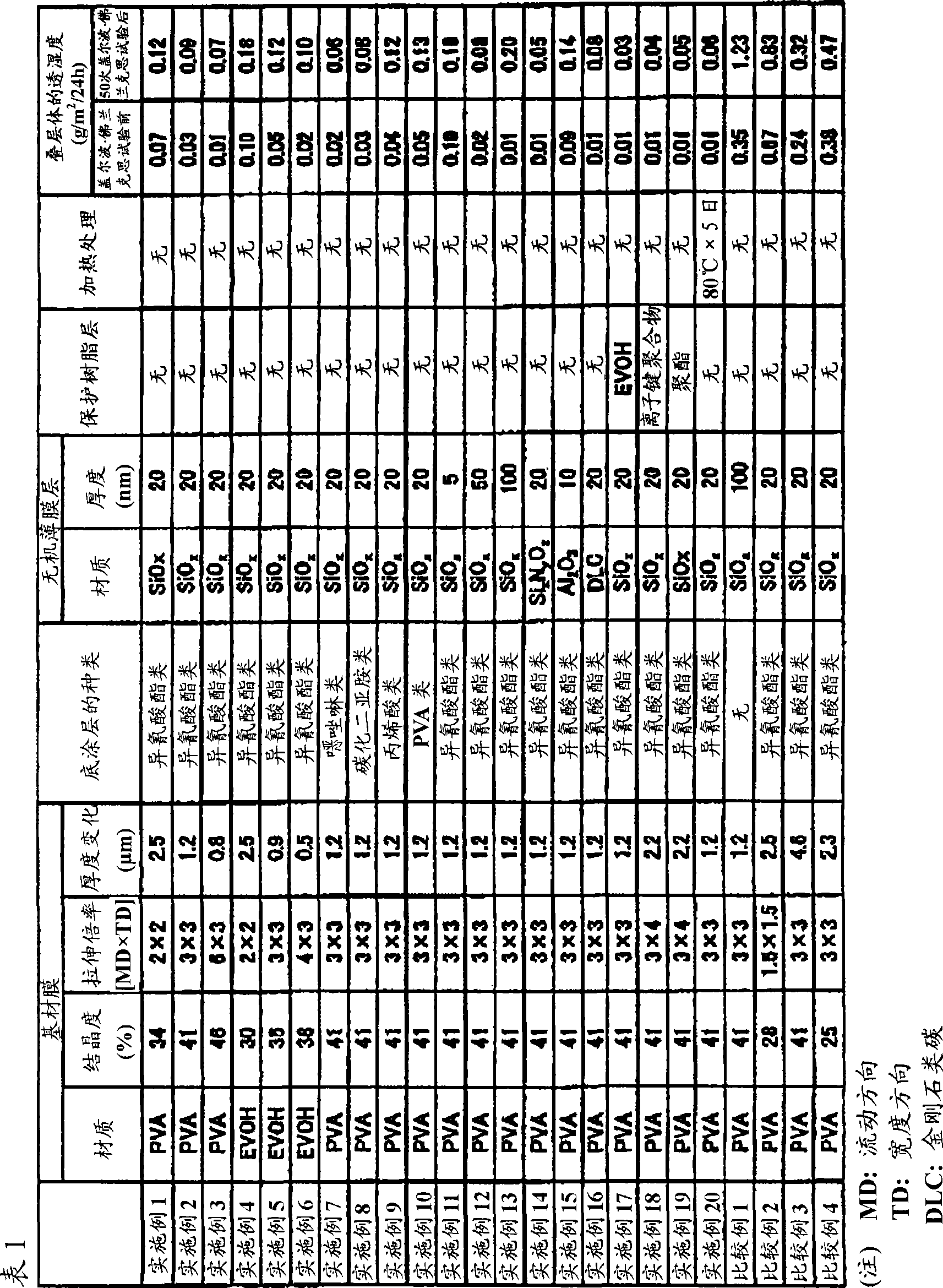

[0116] Using the substrate film with the materials and properties shown in Table 1, a structural layer unit having the undercoat layer and the inorganic thin film layer shown in Table 1 was produced according to Example 1. In addition, in Examples 17 to 19, the protective resin layer shown in Table 1 with a thickness of 100 nm was provided, and in Example 20, heat treatment was performed at 80° C. for 5 days after forming the gas barrier laminate.

[0117] For each structural layer unit, a laminated film was produced in the same manner as in Example 1, and its performance was evaluated. The results are shown in Table 1.

[0118] In addition, in Examples 7, 8, 9, and 10, as the primers of oxazolines, carbodiimides, acrylics, and PVAs used in the primers, respectively, the following primers were used: lotion.

[0119]

[0120] In a flask equipped with a stirrer, reflux cooler, nitrogen introduction tube, thermometer and dropping funnel, add 179 parts of deionized water and 1...

Embodiment 21

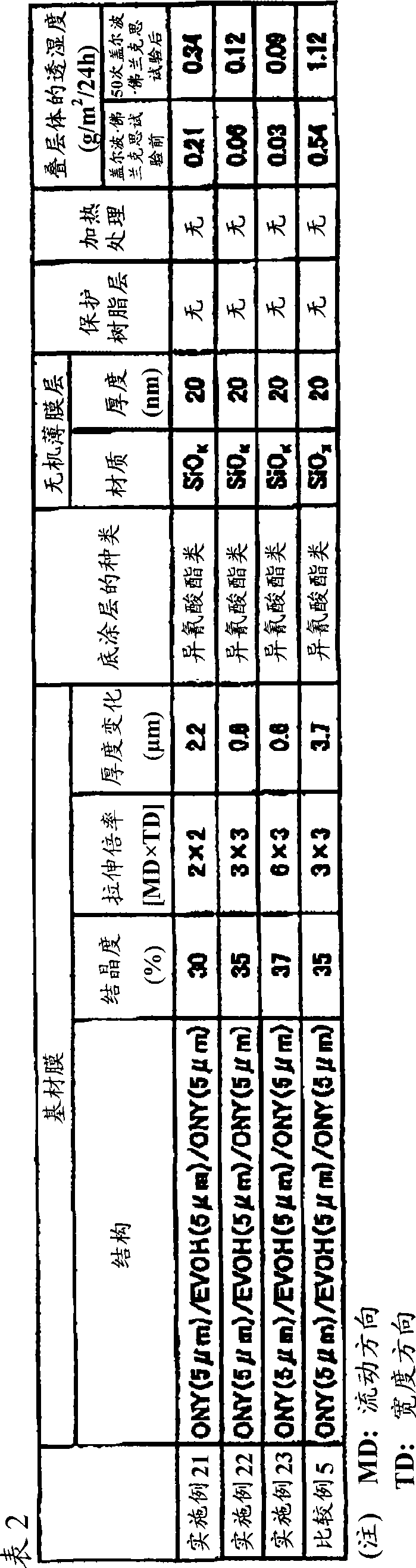

[0141] Use the extruder separately, install the gear pump, make the change of the discharge amount within 2%, and use the T-die head with the surface roughness of 0.1s, at the temperature of 240 ℃, nylon 6 (NOVAMIDE manufactured by Mitsubishi Chemical Co., Ltd. 1022) and the above-mentioned EVOH used as the base film in Example 4 were heated and melted, introduced into a common die, extruded the laminated film, and quenched with a cooling drum to obtain nylon 6 (150 μm) / EVOH Laminated unstretched film of (50 μm) / nylon 6 (150 μm) structure. The film was stretched in the longitudinal direction (MD) at a stretching temperature of 50°C and a stretch ratio of 2.0, and then stretched in the transverse direction (TD) at a stretching temperature of 80°C and a stretch ratio of 2.0 (stretch ratio 2.0 × 2.0), heat treatment at 200°C for 2 seconds to obtain a biaxially stretched coextruded film with a total thickness of 15 μm having a three-layer structure of nylon 6 (5 μm) / EVOH (5 μm) / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com