Novel thiophenedicarboxylic acid-based copolyester as well as preparation method and application thereof

A technology of thiophenedicarboxylic acid-based copolyester and thiophenedicarboxylic acid, which is applied in the field of polymers, can solve the problems of polyester color yellowing and limited application range, and achieve high gas barrier performance, high light transmittance, and melt The effect of low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] One aspect of the embodiments of the present invention provides a method for preparing a novel thiophenedicarboxylic acid-based copolyester, comprising:

[0025] Under a protective atmosphere, make 2,5-thiophenedicarboxylic acid and / or 2,5-thiophenedicarboxylic acid ester, 2,4-thiophenedicarboxylic acid and / or 2,4-thiophenedicarboxylic acid ester, di A new type of thiophenedicarboxylic acid-based copolyester was obtained through the reaction of alcohols, catalysts, stabilizers and antioxidants.

[0026] Further, the catalyst includes esterification catalyst, transesterification catalyst and polycondensation catalyst.

[0027] In some more specific embodiments, the preparation method of the novel thiophenedicarboxylic acid-based copolyester specifically comprises: making 2,5-thiophenedicarboxylic acid and / or 2,5-thiophenedicarboxylic acid The mixture of esterified product, 2,4-thiophenedicarboxylic acid and / or 2,4-thiophenedicarboxylic acid esterified product, glycol, e...

Embodiment 1

[0054] Add 0.1mol of 2,5-thiophenedicarboxylic acid dimethyl ester, 0.1mol of 2,4-furandicarboxylic acid dimethyl ester, 0.32mol of ethylene glycol, and 0.0003mol of anhydrous zinc acetate into the reactor, pump Vacuum and nitrogen replacement three times, start stirring, gradually raise the temperature to 180 ° C, react for 3 hours, then add 0.0003 mol of antimony trioxide, 0.0004 mol of triphenyl phosphate, 0.00025 mol of tetrakis [β-(3,5-di-tert-butyl base-4-hydroxyphenyl)propionic acid]pentaerythritol ester, and then slowly evacuate to below 60Pa, and raise the temperature to 220°C, and react for 4.5h to obtain polyethylene thiophene dicarboxylate, which is polyethylene thiophene dicarboxylate ester 1 The data of H-NMR (deuterated trifluoroacetic acid as solvent) are: the hydrogen displacement of thiophene ring is 7.57ppm, 7.78ppm and 8.68ppm; the hydrogen atom displacement of ethylene glycol methylene is 4.20ppm.

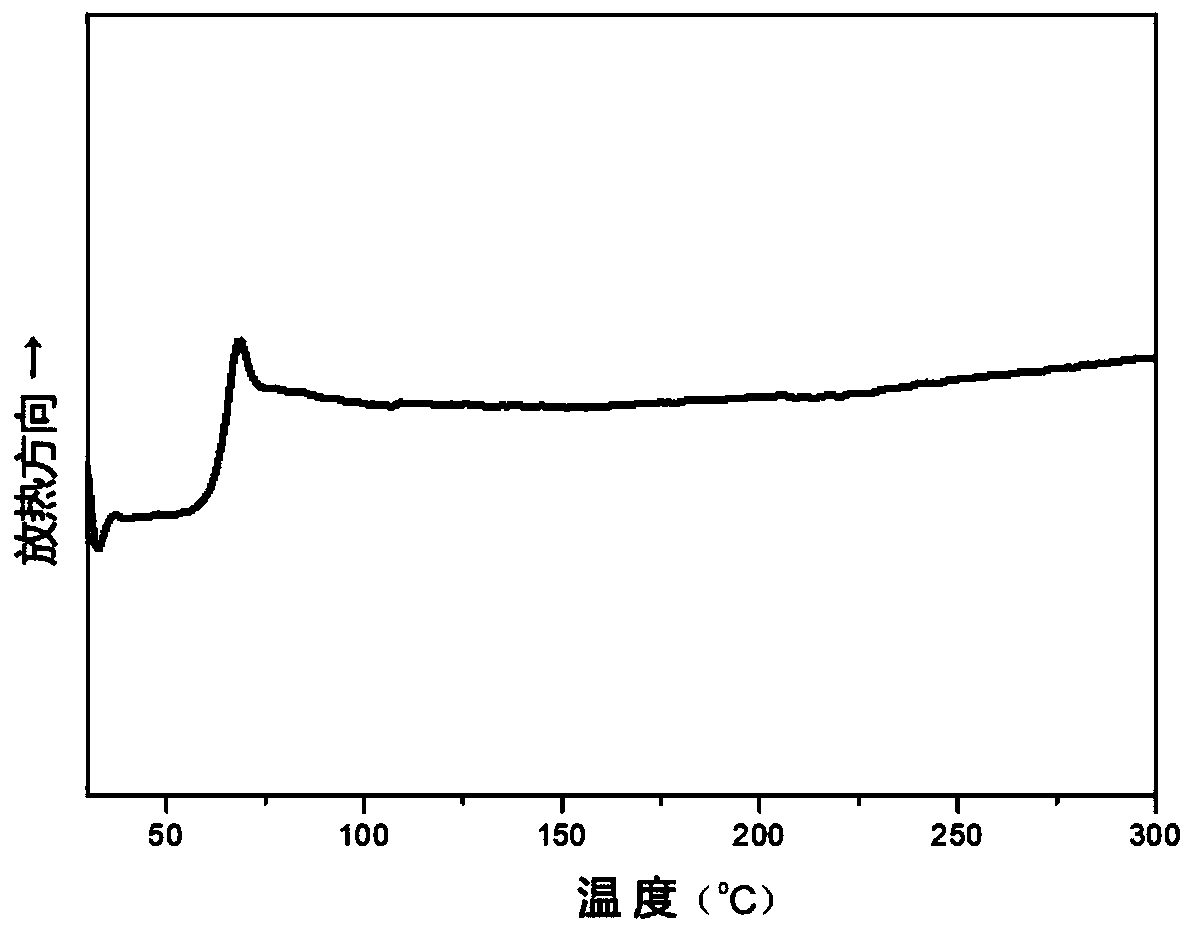

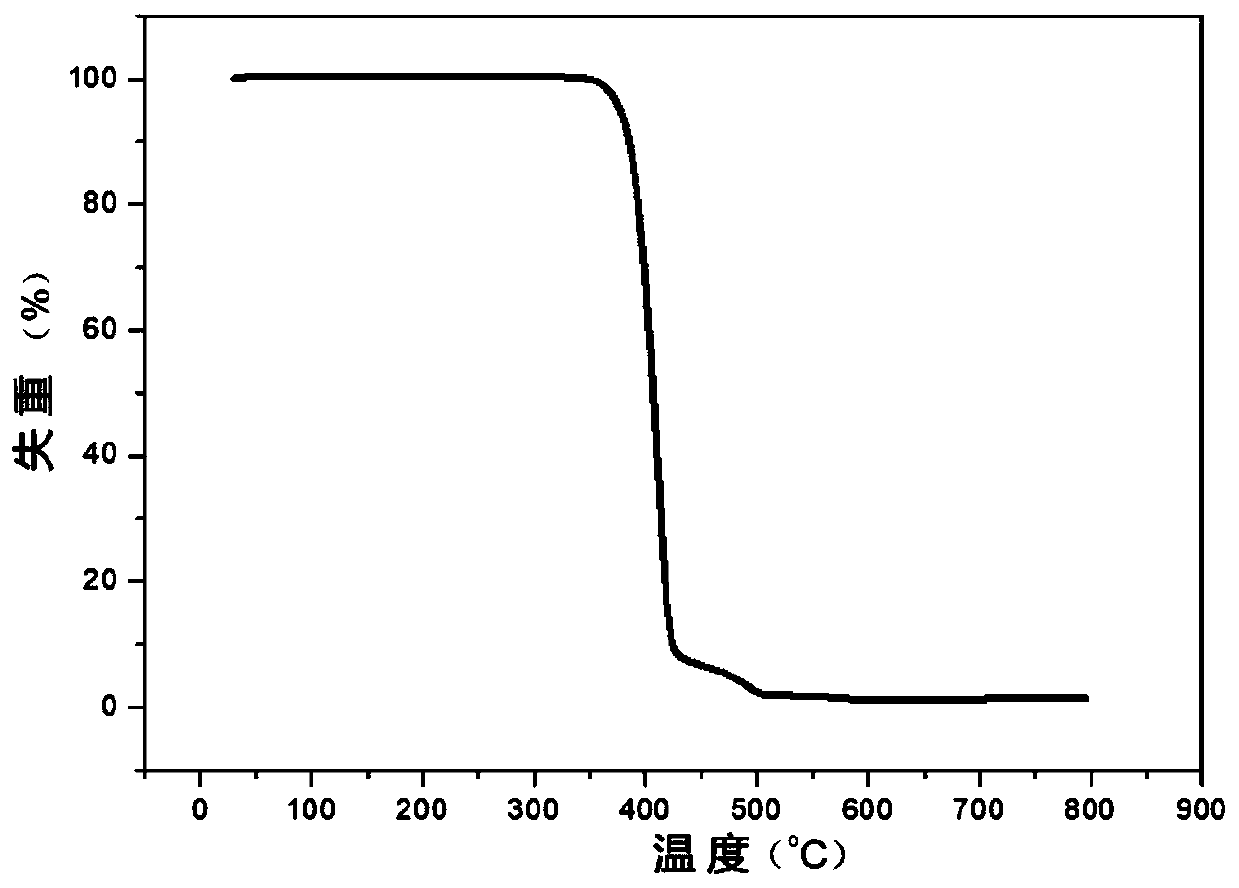

[0055] After testing, the relative number-average molecu...

Embodiment 2

[0057] Add 0.16mol of dimethyl 2,5-thiophenedicarboxylate, 0.04mol of dimethyl 2,4-furandicarboxylate, 0.32mol of 1,3-propanediol, and 0.0004mol of anhydrous zinc acetate into the reactor , evacuate, replace with nitrogen for three times, start stirring, gradually raise the temperature to 180°C, react for 3 hours, then add 0.00045mol ethylene glycol antimony, 0.0006mol trimethyl phosphate, 0.0004mol tetrakis[β-(3,5-di tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, then slowly evacuate to below 60Pa, and raise the temperature to 210°C, and react for 3.0h to obtain poly(trimethylene thiophene dicarboxylate). After testing, poly(trimethylene thiophene dicarboxylate) The relative number-average molecular mass of the ester is 43000g / mol; the visible light transmittance is 89% (cut-off 700nm wavelength), the melt viscosity is lower than 720Pa·S at 220°C, and the glass transition temperature is 34.2°C; 5% The thermal weight loss temperature is 385°C; the tensile stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com