Super wear-resistant, anti-skid and stain-resistant floor ultraviolet curing coating system

A UV and ultra-wear-resistant technology, applied in coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problem of complex coating process and failure to achieve the first level of stain resistance, wear resistance, anti-skid, and micro-scratch failure to reach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

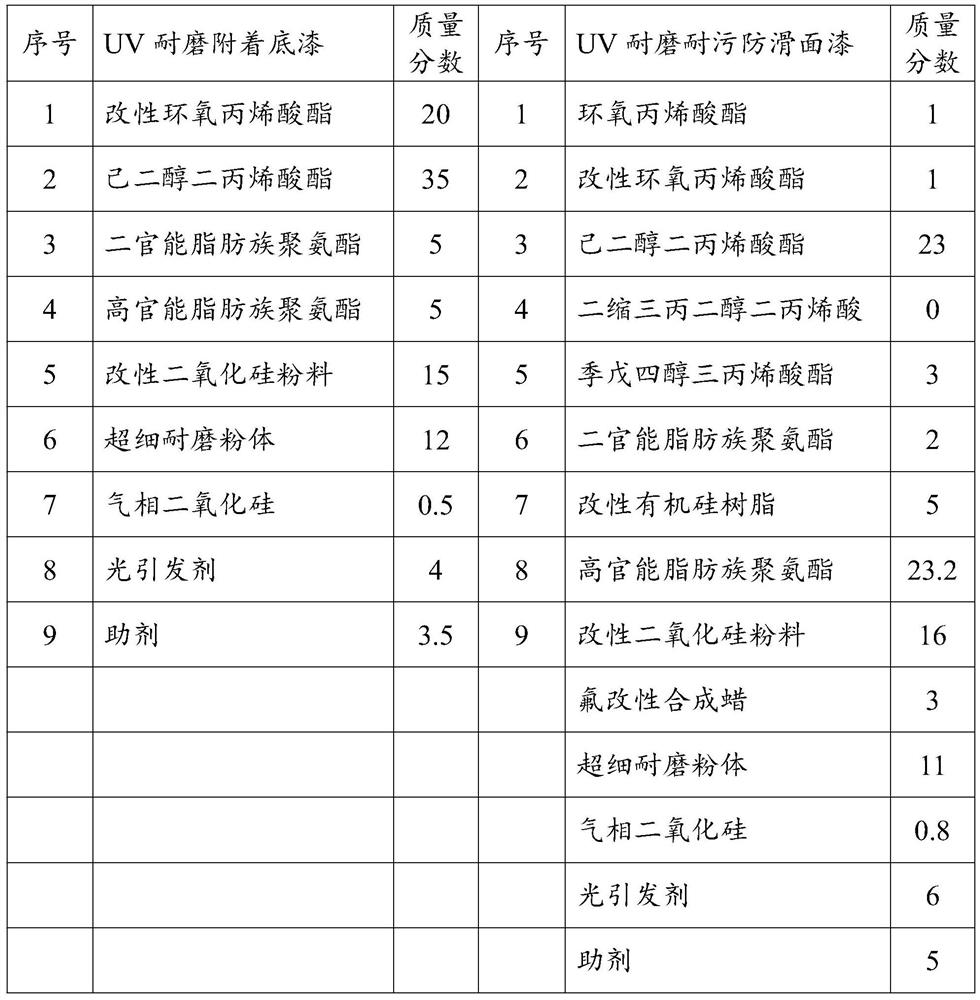

Embodiment 1

[0026] A UV curing coating system for super wear-resistant, anti-slip and stain-resistant floors, the components and mass fractions of UV wear-resistant, anti-slip and stain-resistant topcoat and UV wear-resistant adhesion primer are listed in Table 1.

[0027] Preparation of UV wear-resistant anti-skid stain-resistant topcoat: the epoxy acrylate, modified silicone resin, modified epoxy acrylate, hexanediol diacrylate, tripropylene glycol diacrylate, pentaerythritol triacrylate , two-functional aliphatic polyurethane, high-functional aliphatic polyurethane, modified silica powder, fluorine-modified synthetic wax, ultrafine wear-resistant powder, fumed silica, photoinitiator and additives are put into the reaction in sequence In the kettle, heat to 70°C, and disperse at a high speed of 1500rpm for 3 hours until uniform without oil shrinkage, and then a UV wear-resistant, non-slip and stain-resistant topcoat can be obtained.

[0028] Preparation of UV wear-resistant adhesion pri...

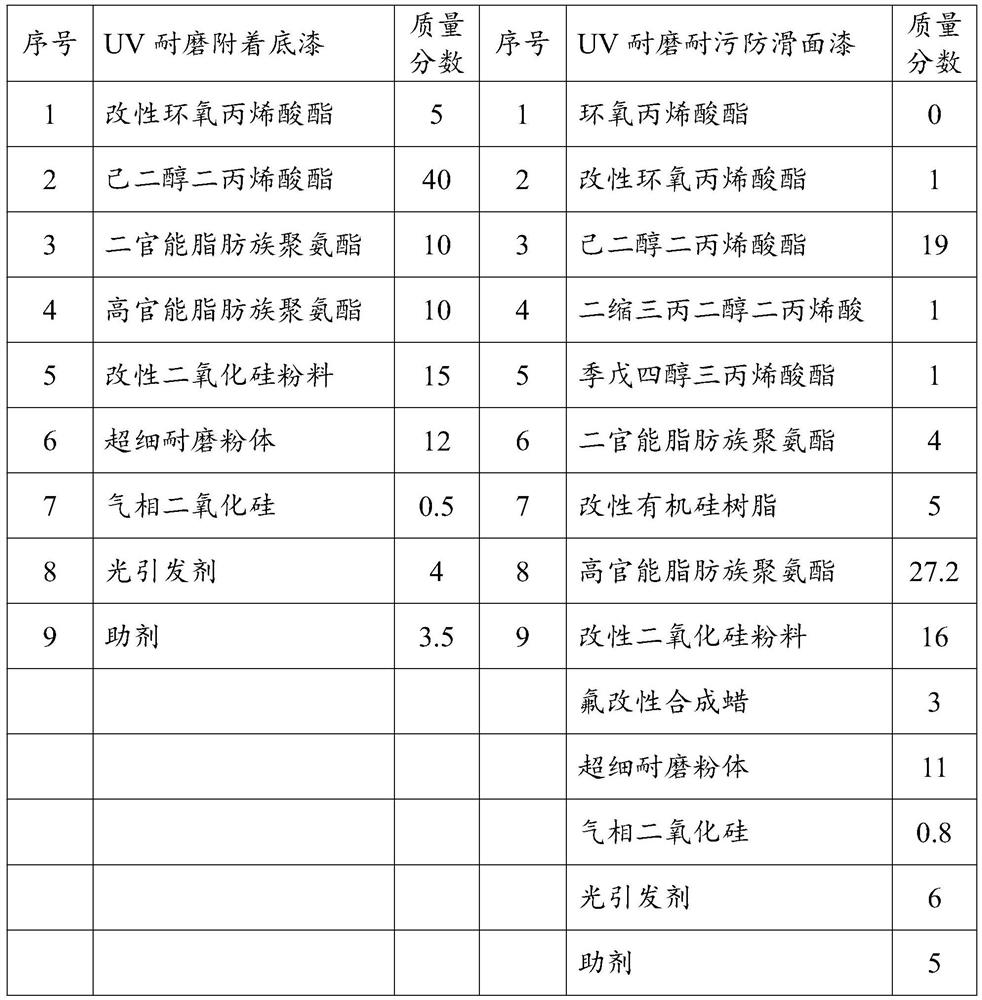

Embodiment 2

[0033] A UV curing coating system for super wear-resistant, anti-slip and stain-resistant floors, the components and mass fractions of UV wear-resistant, anti-slip and stain-resistant topcoat and UV wear-resistant adhesion primer are listed in Table 2.

[0034] The preparation process of the UV wear-resistant anti-skid and stain-resistant topcoat and the UV wear-resistant adhesion primer is the same as that in Example 1.

[0035] On the SPC substrate, apply 2 coats of UV wear-resistant adhesion primer, and after curing, apply 1 coat of UV wear-resistant, non-slip and stain-resistant topcoat, and cure to obtain a paint film.

[0036] The composition of the UV wear-resistant antiskid stain-resistant finish paint of table 2 embodiment 2 and the UV wear-resistant adhesion primer, %

[0037]

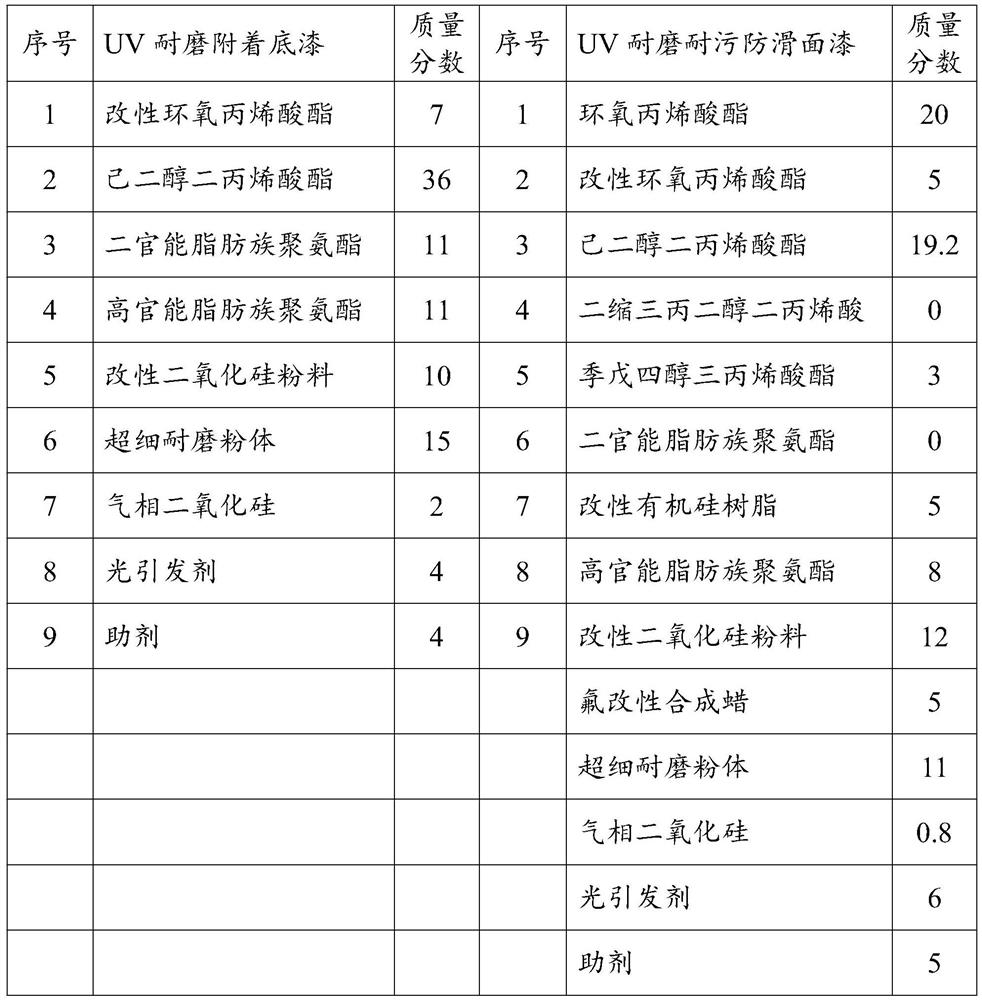

Embodiment 3

[0039] A UV curing coating system for super wear-resistant, anti-slip and stain-resistant floors, the components and mass fractions of UV wear-resistant, anti-slip and stain-resistant topcoat and UV wear-resistant adhesion primer are listed in Table 3.

[0040] The preparation process of the UV wear-resistant anti-slip and stain-resistant topcoat and the UV wear-resistant adhesion primer is the same as that in Example 1.

[0041] On the PVC substrate, apply 2 coats of UV wear-resistant adhesion primer, place and cure, and then apply 1 coat of UV wear-resistant, non-slip and stain-resistant topcoat, and cure to obtain a paint film.

[0042] The composition of the UV wear-resistant antiskid stain-resistant finish paint of table 3 embodiment 3 and the UV wear-resistant adhesion primer, %

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com