Bright film printing paste and preparation method thereof

A technology of printing paste and bright film, which is applied in dyeing, textiles and papermaking, etc. It can solve the problems of unseen technical disclosure information and unsatisfactory use effect, and achieve the effect of strong transparency, good transparency and high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

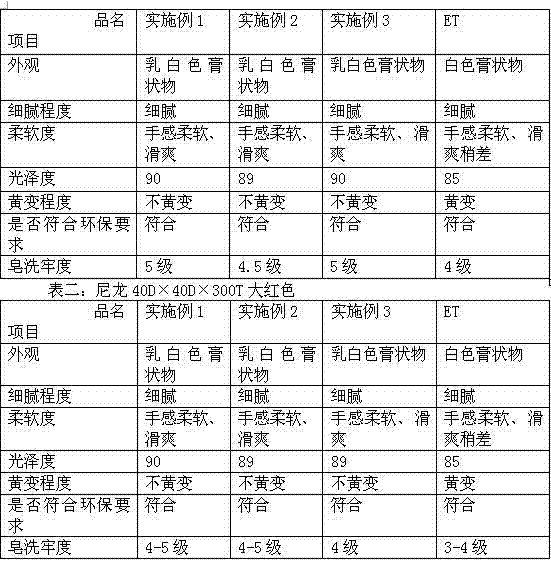

Examples

Embodiment 1

[0019] (1) Emulsified mixed monomer: add 20 grams of itaconic acid, 350 grams of butyl acrylate, 71 grams of hydroxyethyl acrylate, 10 grams of tripropylene glycol diacrylate, 42 grams of acrylonitrile, fatty alcohol polyoxyethylene into a stainless steel kettle 2 grams of ether 23E9, 530 grams of deionized water, stirred to make emulsion, stand-by;

[0020] (2) Initiate polymerization reaction: Take 20% of the total amount of the emulsion and add it to the reaction kettle, raise the temperature to 80-82°C, add a mixture of 1.27 grams of initiator ammonium persulfate and 10 grams of deionized water to initiate, and then in At 80-82°C, add 820 grams of the remaining emulsion dropwise, and at the same time add dropwise a mixture of 0.63 grams of ammonium persulfate and 10 grams of deionized water. After 1-2 hours, the dropwise addition is completed, and the temperature is kept at 80-82°C for 2-3 hours. , then lower the temperature to 30-40°C, and adjust the pH value to 7±0.5...

Embodiment 2

[0023] (1) Emulsified mixed monomer: add 20.5 grams of itaconic acid, 355 grams of butyl acrylate, 72 grams of hydroxyethyl acrylate, 10.5 grams of tripropylene glycol diacrylate, 43 grams of acrylonitrile, fatty alcohol polyoxyethylene into a stainless steel kettle Ether 23E9 is 2.1 grams, deionized water 550 grams, stir to make emulsion, stand-by;

[0024] (2) Initiate polymerization reaction: Take 20% of the total amount of the emulsion and add it to the reaction kettle, raise the temperature to 80-82°C, add a mixture of 1.27 grams of initiator ammonium persulfate and 10 grams of deionized water to initiate, and then in Add 842.48 grams of the remaining emulsion at a temperature of 80-82°C, and at the same time add a mixture of 0.73 grams of ammonium persulfate and 10 grams of deionized water, dropwise in 1-2 hours, and keep warm at 80-82°C for 2-3 hours , then lower the temperature to 30-40°C, and adjust the pH value to 7±0.5 with 20% ammonia water by mass percentage; ...

Embodiment 3

[0027] (1) Emulsified mixed monomer: add 21 grams of itaconic acid, 360 grams of butyl acrylate, 73 grams of hydroxyethyl acrylate, 10.5 grams of tripropylene glycol diacrylate, 44 grams of acrylonitrile, fatty alcohol polyoxyethylene into a stainless steel kettle Ether 23E9 is 2.3 grams, deionized water 580 grams, stir to make emulsion, stand-by;

[0028] (2) Initiate polymerization reaction: Take 20% of the total amount of the emulsion and add it to the reaction kettle, raise the temperature to 80-82°C, add a mixture of 1.27 grams of initiator ammonium persulfate and 10 grams of deionized water to initiate, and then in Add 872.64 grams of the remaining emulsion at a temperature of 80-82°C, and at the same time add a mixture of 0.83 grams of ammonium persulfate and 10 grams of deionized water dropwise. After 1-2 hours, the dropwise addition is completed, and the temperature is kept at 80-82°C for 2-3 hours. , then lower the temperature to 30-40°C, and adjust the pH value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com