Windshield glass repairing agent and preparation method thereof

A windshield glass repairing and repairing agent technology, which is applied in the direction of modified epoxy resin adhesives, etc., can solve the problems that the strength cannot be maintained for a long time, and the glass repairing agent has poor hidden marks, etc. mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

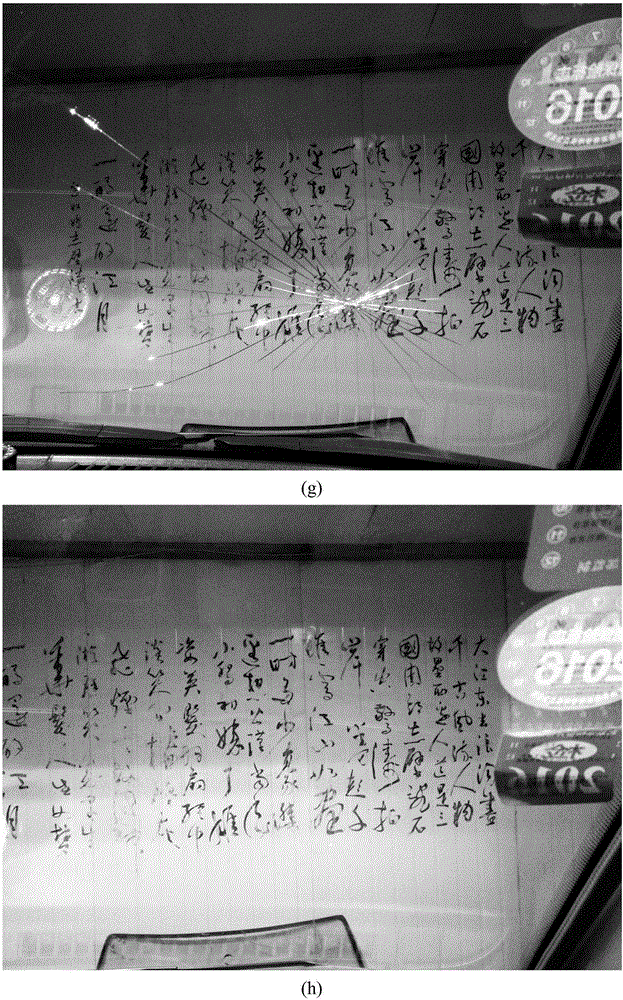

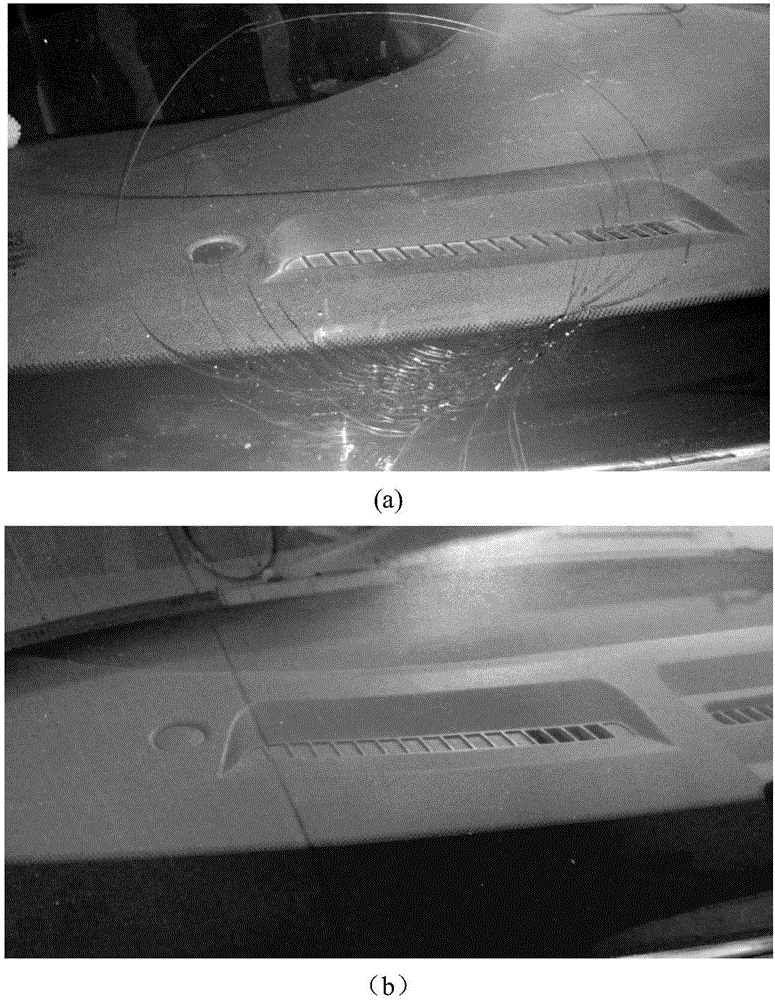

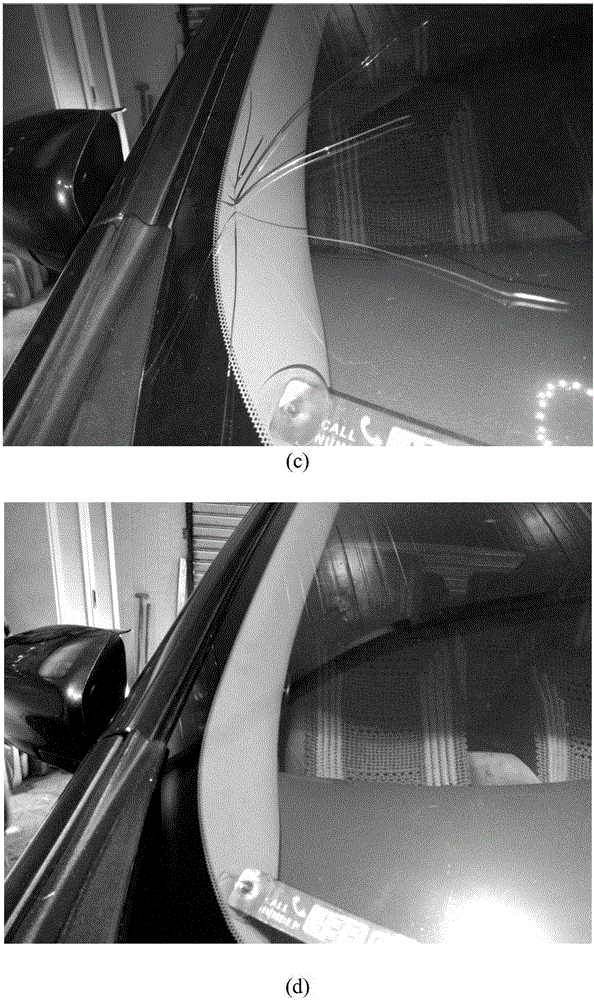

Image

Examples

Embodiment 1

[0038] (1) Under stirring conditions, add 15L epoxy resin E-44 into the reaction vessel, heat to 90°C, then add 12.5L reactive diluent tripropylene glycol diacrylate (TPGDA) and 9L ethyl acrylate; then The temperature of the solution was raised to 110°C, and the condensation reaction was carried out for 45 minutes;

[0039] (2) Keep the solution temperature at 110°C, add dropwise a mixed solution of 3.65L of acrylic acid and 0.05L of hydroquinone within 25 to 30 minutes, and continue the reaction for 20 minutes;

[0040] (3) Add 8L pentaerythritol triacrylate (PETA) and 1.5L photoinitiator 2-hydroxyl-2-methyl-1-phenyl-1-acetone (HMPF) respectively in the solution, stir for 20 minutes; Then the solution Cool to room temperature to obtain the restorative agent mother liquor;

[0041] (4) Take 15L of repairing agent mother liquor, add 16.5L of TPGDA, 17L of MMA, 0.6L of coupling agent KH550 and 0.9L of photoinitiator HMPF, stir well and leave it for 240 hours to obtain the repai...

Embodiment 2

[0048] (1) Under stirring conditions, add 3.5L epoxy resin E-31 into the reaction vessel, heat to 85~86°C, then add 2.2L reactive diluent TPGDA and 2L ethyl acrylate; then raise the temperature of the solution to 105 ~106°C, conduct condensation reaction for 60 minutes;

[0049] (2) Keep the solution temperature at 105-106°C, add dropwise a mixed solution of 0.75L acrylic acid and 0.015L hydroquinone within 40 minutes, and continue the reaction for 25 minutes;

[0050] (3) Add 2L of PETA and 0.4L of HMPF to the solution, stir for 25 minutes; then cool the solution to room temperature to obtain the restoration agent mother liquor;

[0051] (4) Take 2.8L of restorative agent mother liquor, add 3L of TPGDA, 3.2L of MMA, 0.1L of coupling agent KH570 and 1.5L of HMPF respectively, stir evenly and leave for 200 hours to obtain the repair agent.

[0052] After testing, the property parameters of the restorative agent prepared by the above method are:

[0053] 1. Curing time: the init...

Embodiment 3

[0058] (1) Under stirring conditions, add 3.3L epoxy resin E-35 into the reaction vessel, heat to 93~95°C, then add 2L reactive diluent TPGDA and 1.6L ethyl acrylate; then raise the temperature of the solution to 113 ~115°C, conduct condensation reaction for 30 minutes;

[0059] (2) Keep the solution temperature at 113-115°C, add dropwise a mixed solution of 0.7L acrylic acid and 0.02L hydroquinone within 35 minutes, and continue the reaction for 30 minutes;

[0060] (3) Add 1.4L PETA and 0.2L photoinitiator HMPF respectively to the solution, stir for 30 minutes; then cool the solution to room temperature to obtain the restoration agent mother liquor;

[0061] (4) Take 3.2L of restorative agent mother liquor, add 3.5L of TPGDA, 3.7L of MMA, 0.15L of coupling agent KH550 and 0.2L of photoinitiator HMPF, stir well and leave it for 220 hours to obtain the repair agent.

[0062] After testing, the property parameters of the restorative agent prepared by the above method are:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Heat resistant | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com