Low-smoke halogen-free flame-retardant polyolefin cable material

A technology of polyolefin cable material and low-density polyethylene, which is applied in the field of low-smoke, halogen-free flame-retardant polyolefin cable material and its preparation, can solve the problem of poor low temperature resistance, poor weather resistance, affecting the physical and mechanical properties of cable material and Process performance and other issues to achieve the effect of improving uniformity and surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

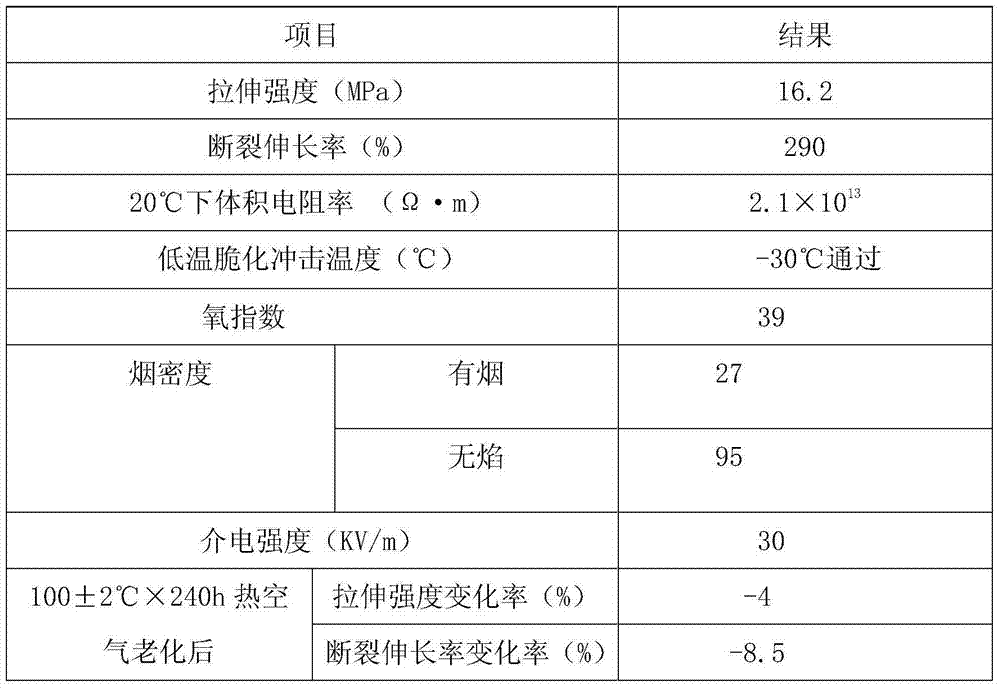

Image

Examples

Embodiment Construction

[0011] Low-smoke halogen-free flame-retardant polyolefin cable material, made of the following weight (kg) raw materials:

[0012] Ethylene-vinyl acetate copolymer (EVA) 35, high-density polyethylene (HDPE) 60, chlorinated polyethylene 4, low-density polyethylene 18, aluminum hydroxide [Al(OH)3] 45, magnesium hydroxide [Mg (OH) 2] 35, terminal amine group polyol ester 5, tributyl phosphate 2, epoxy soybean oil 7, glycerin, 6, antioxidant 10351, barium stearate 2, nano silicon carbide 1, di-condensed three Propylene glycol diacrylate 2, phosphate ester 2, PE wax 1.5, silane coupling agent KH-5501, zinc stearate 2, modified filler 17.

[0013] The preparation method of the cable material of the present invention:

[0014] Weigh each component raw material according to the formula ratio, mix the weighed component raw materials in a high-speed mixer, and then mix them at a temperature range of 125-165℃, twin-screw extrusion, and eagerly grinding the surface Pelletizing, feeding by cycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com