Photocuring microwave absorbing coating with barium ferrite doped with polypyrrole as wave absorber

A technology of barium ferrite and wave-absorbing coatings, applied in radiation-absorbing coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of narrow absorption frequency band of conductive high polymer materials, and achieve excellent mechanical properties and weather resistance performance, simple production process, widening absorption band effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

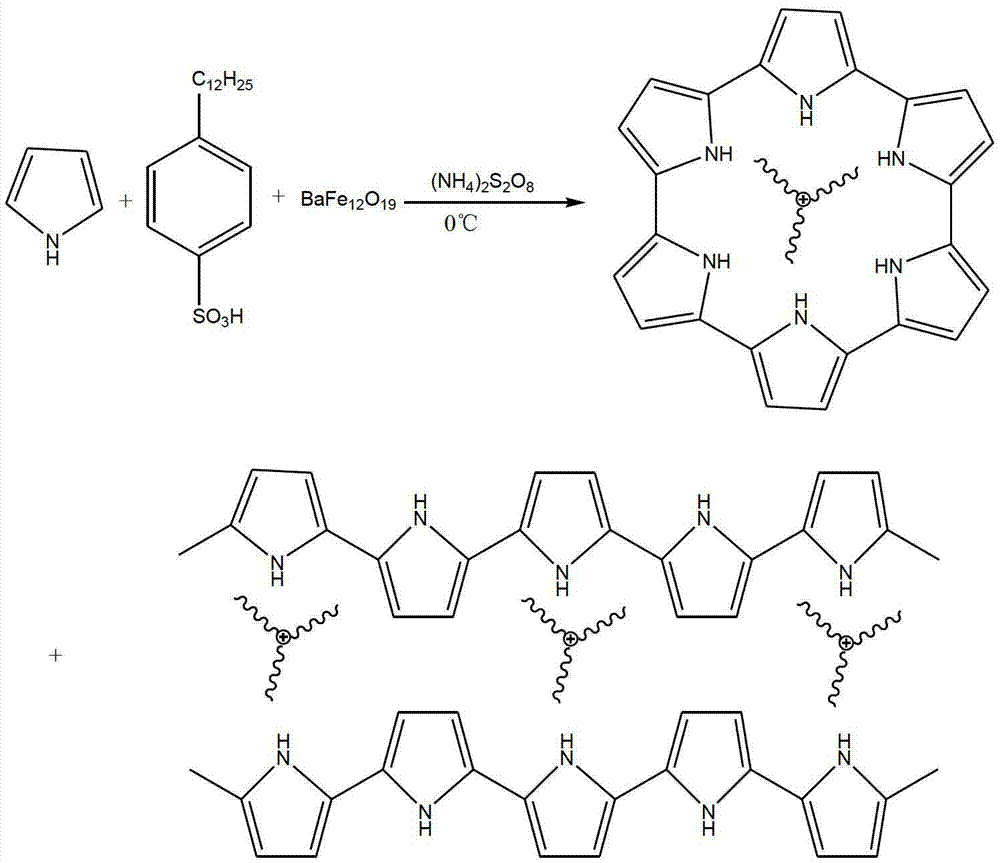

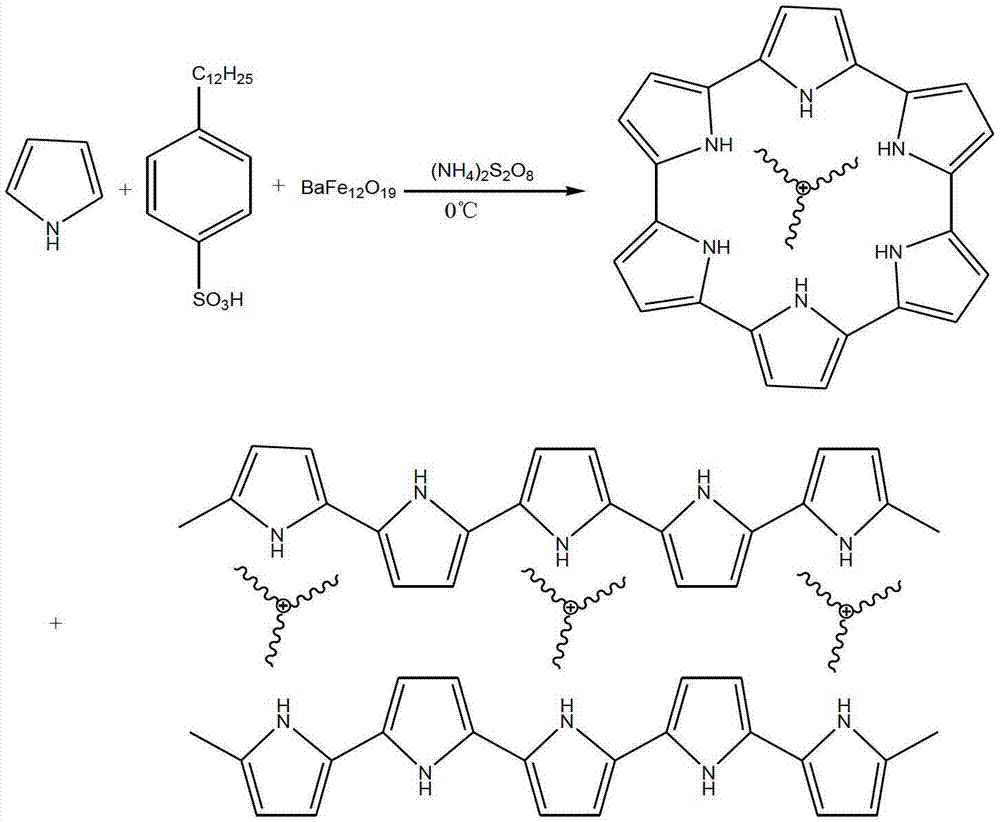

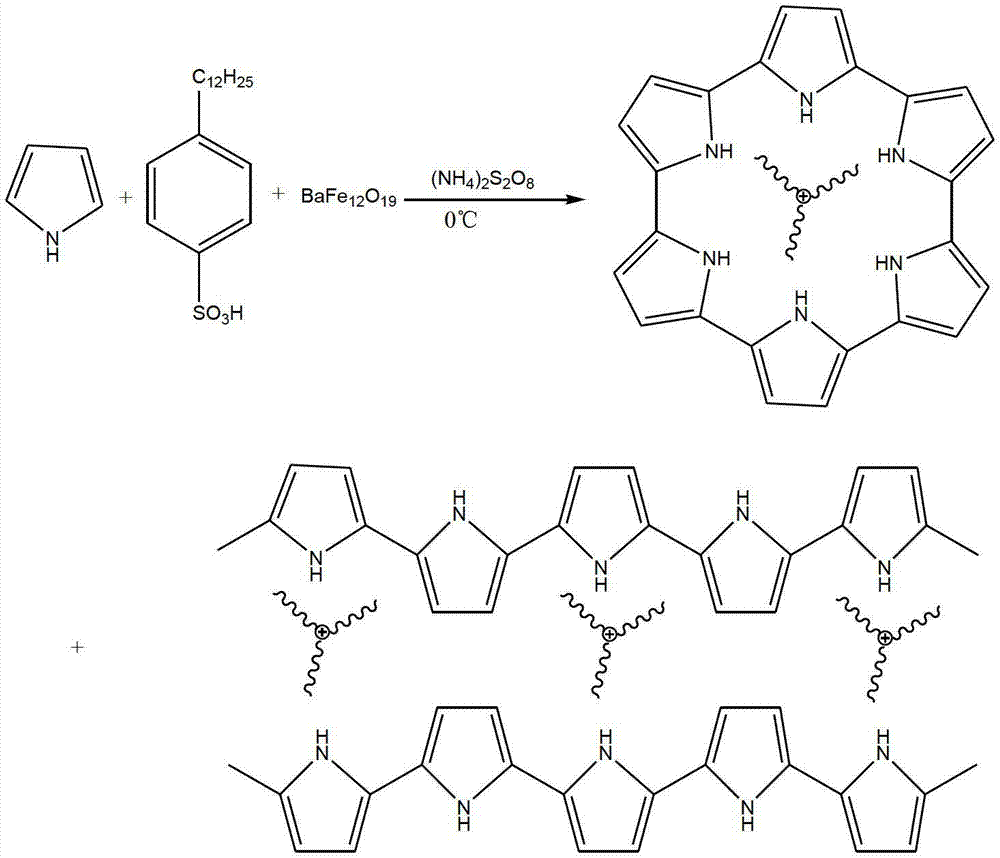

[0022] Preparation of barium ferrite doped polypyrrole absorber

[0023] Dissolve 1 g of ammonium persulfate (APS) solution in 30 mL of 0.1 mol / L hydrochloric acid and put it in the refrigerator for later use.

[0024] 0.48g of barium ferrite BaFe 12 o 19 (BaF 2 ) and 3.48g of sodium dodecylbenzenesulfonate (DBSA) were added to a 100mL0.1mol / L hydrochloric acid flask, ultrasonically dispersed for 1h, then 7mL of pyrrole (Py) was added, and then ultrasonically dispersed for 1h to obtain a uniformly dispersed The solution. Keep the solution at 0-2°C in an ice-water bath, slowly add 30mL of ammonium persulfate hydrochloric acid solution dropwise therein, drop it in about 15 minutes, and keep the reaction temperature at 0-2°C for 12h. After the reaction is completed, filter with suction, wash with a large amount of ethanol and deionized water until the filtrate is colorless, dry the reaction product in vacuum at 60°C for 24 hours, and grind it evenly to obtain barium ferrite-d...

Embodiment 2

[0034] The preparation of barium ferrite-doped polypyrrole absorber is as in Example 1.

[0035] Preparation of paint:

[0036]The mass ratio formula of 200g specification paint components is: 45% (90g) of hexafunctional aliphatic urethane acrylate, 25% (50g) of tripropylene glycol diacrylate as monomer diluent; 5% of trimethylolpropane triacrylate (10g); barium ferrite BaFe 12 o 19 Doped polypyrrole absorber 20% (40g); 1173 photoinitiator 4% (8g); defoamer (modified polysiloxane-cyclohexanone / aromatic hydrocarbon solvent) and leveling agent (poly Acrylate solution) each 0.5% (1g). According to the proportion of the formula, hexafunctional aliphatic urethane acrylate, monomer diluent tripropylene glycol diacrylate, barium ferrite BaFe 12 o 19 Doped with polypyrrole wave absorber, triacrylate adhesion promoter, photoinitiator, defoamer and leveling agent and mixed uniformly to make light-cured wave absorbing coating.

[0037] The coating can be applied to the magnesium-al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Pencil hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com