Anti-electromagnetic radiation antibacterial film adhered to protective clothing and preparation method thereof

A technology for preventing electromagnetic radiation and protective clothing, applied in the field of anti-electromagnetic radiation antibacterial film and its preparation, can solve the problems of secondary pollution of space environment, easy growth of bacteria, unsatisfactory electromagnetic radiation protection effect, etc., to achieve strong antibacterial effect, prevent Strong oxidative and antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

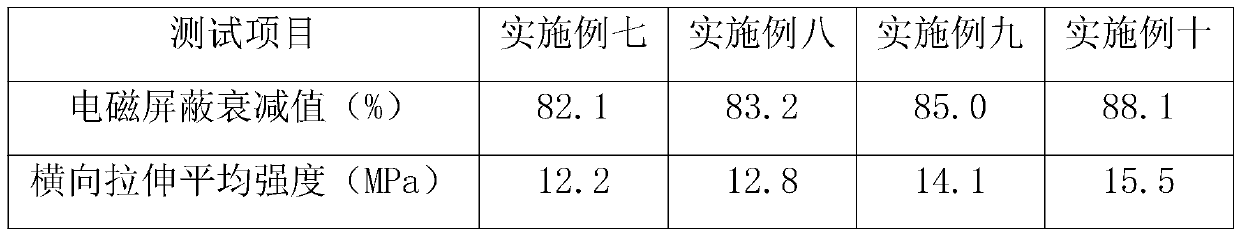

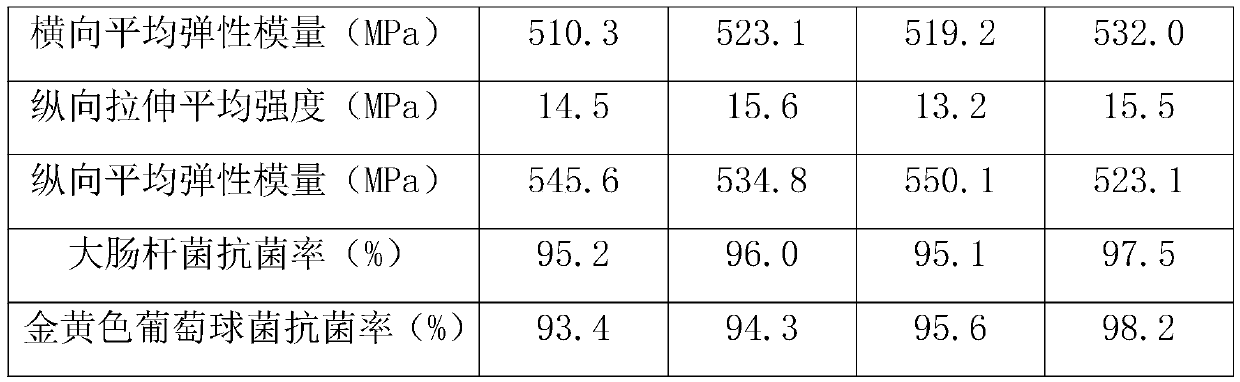

Examples

Embodiment 1

[0025] Embodiment one: Fe 3 o 4 preparation of

[0026] Preparation of Fe by hydrothermal method 3 o 4 : Measure polyethylene glycol and add it to deionized water to configure a viscous solution with a concentration of 5mol / L, weigh 0.3mol ferrous sulfate (FeSO 4 ·7H 2 O) and 0.15mol sodium thiosulfate (NaS 2 o 3 ·5H 2 O), put them into the liner of the polytetrafluoroethylene reactor together, then add 0.88L of viscous liquid and stir evenly, then quickly pour 0.12L of sodium hydroxide solution with a concentration of 5mol / L and stir, the surface generates the precursor Fe (OH) 2 After continuing to stir and mix, ultrasonically oscillate for 20 minutes under the condition of frequency 30kHz and power 350W, react in the reaction kettle at 180°C for 8-11 hours, cool to room temperature naturally, take out the reactant and wash it with deionized water magnetic separation time, vacuum drying at 65-70°C for 10 hours to obtain Fe 3 o 4 particles. to Fe 3 o 4 Particle ...

Embodiment 2

[0027] Embodiment two: Fe 3 o 4 -SiO 2 preparation of

[0028] In every liter of deionized water, disperse the Fe prepared by 5g embodiment one 3 o 4 Nanoparticles, add 80mL5mol / L HCl and 200mL5mol / L trisodium citrate solution, stir for 1.5h, magnetically separate to obtain modified Fe 3 o 4 Nanoparticles, sodium citrate adsorbed on Fe 3 o 4 On the surface of the nanoparticles, the Fe 3 o 4 The surface potential is favorable for Fe 3 o 4 The nanoparticles overcome the magnetic dipole moment, and the modified Fe 3 o 4 Ultrasonic dispersion in an ethanol solution containing 20w% ammonia water, stirring and adding dropwise 5mL orthosilicate ethyl silicate dispersed with nickel nanopowder, nickel nanopowder with mass concentration of 5% dispersed in the orthosilicate ethyl ester, orthosilicic acid Continue to stir for 24 h after the ethyl ester is added dropwise, wash with water and ethanol magnetic separation until the solution is neutral, and the monolayer SiO obtai...

Embodiment 3

[0029] Embodiment three: ZnO-Fe 3 o 4 -SiO 2 preparation of

[0030] Graphene oxide was prepared by the Hummers method, and the graphene oxide was ultrasonically dispersed in deionized water to form a suspension with a mass concentration of 1.2 mg / mL; the zinc particles were put into a tablet machine to be pressed into flakes, and then put into alumina In the crucible, place the alumina crucible in the furnace, heat up to 450°C at a rate of 8°C / min and keep it at a constant temperature for 2 hours, then raise the temperature at a rate of 5°C / min to 950°C and keep it at a constant temperature for 1 hour. Cool with the furnace and grind to obtain Four-needle ZnO powder; Get the Fe that embodiment two prepares 3 o 4 -SiO 2 Nanoparticles were added to the suspension, ultrasonically dispersed for 30min at a frequency of 25kHz and a power of 100W, and then 2 times Fe 3 o 4 -SiO 2 Quality tetraacicular ZnO powder is stirred at a speed of 450-600r / min for 1 hour to obtain a di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com