Preparation method of a self-assembled porous polyaniline/cobalt core-shell spherical structure absorbing material

A spherical structure and wave-absorbing material technology, applied in the field of materials, can solve the problems of poor bonding between cobalt and polyaniline, single loss mechanism, and limited wave-absorbing effect, so as to promote uniform dispersion, enhance electromagnetic wave absorption, and enhance multiple reflections and scattering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

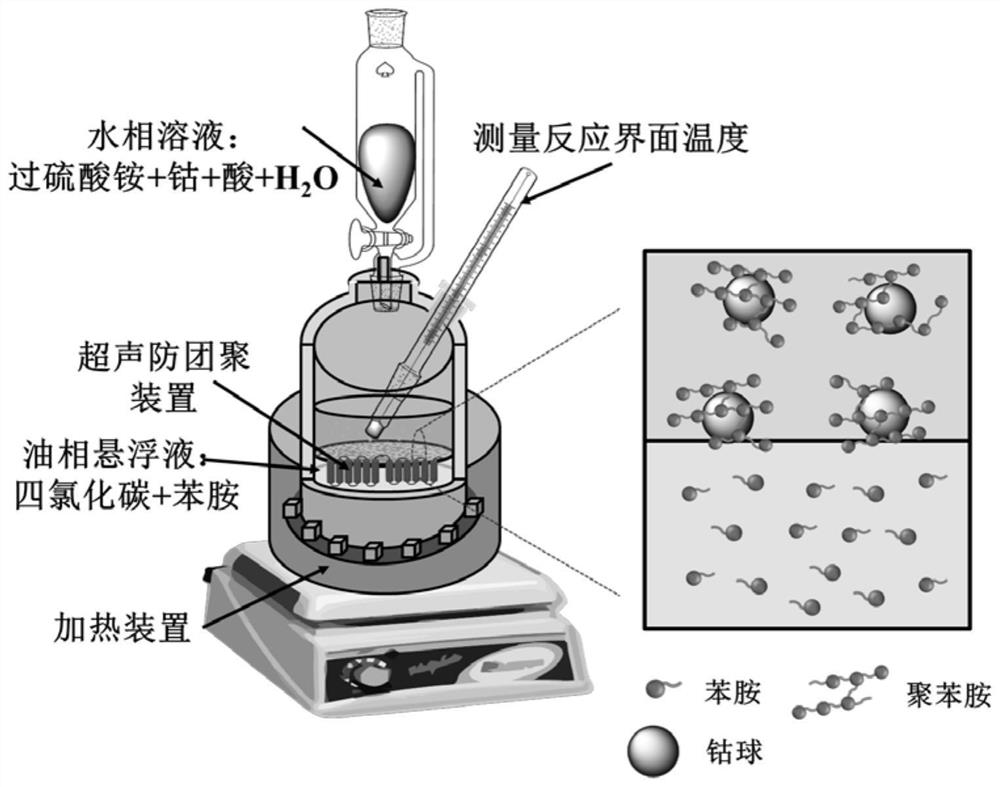

[0037] This example provides a method for preparing a self-assembled porous polyaniline / cobalt core-shell spherical structure absorbing material:

[0038] Step 1, dissolving aniline in an organic solvent to form an oil phase suspension.

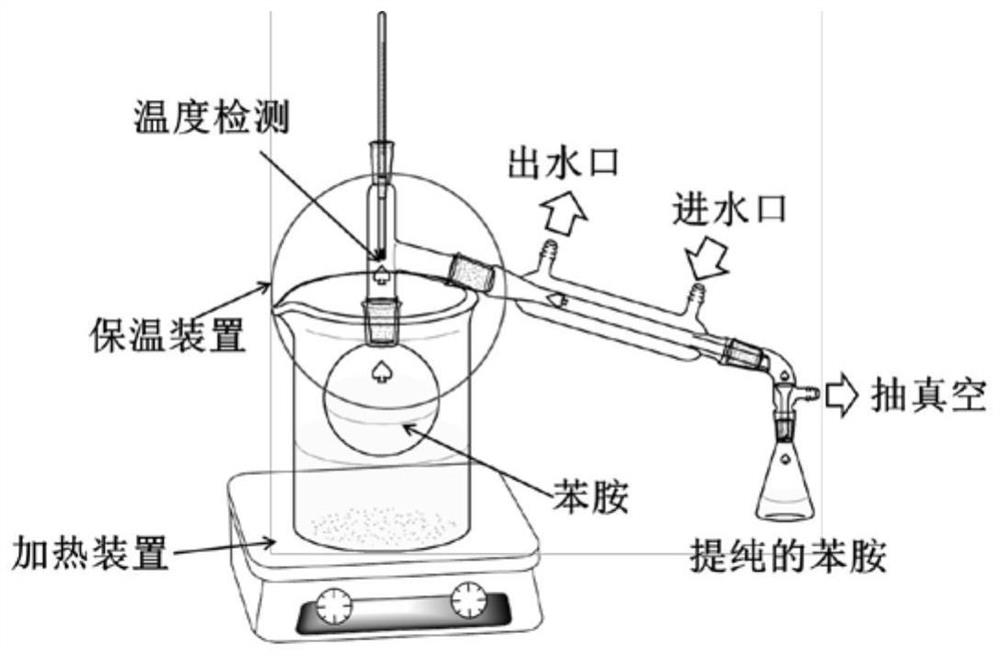

[0039] Specifically, aniline is purified by distillation under reduced pressure, such as figure 1 As shown, then, the purified aniline was dissolved in carbon tetrachloride organic solvent, the concentration of aniline was 0.05mol / L, stirred for 1h, and the stirring speed was 50rpm, to obtain an oil phase suspension with uniform dispersion of aniline.

[0040] Step 2, performing surface modification with a silane coupling agent and nitration surface modification on the cobalt powder to obtain a modified cobalt powder whose surface is rich in amino groups.

[0041] The specific method of modification is:

[0042] Step a. Prepare 50mL mixed solution according to the volume fraction of ethanol: water = 9:1, add 2g of cobalt powder into the sol...

Embodiment 2

[0053] This example provides a method for preparing a self-assembled porous polyaniline / cobalt core-shell spherical structure absorbing material:

[0054] Step 1, dissolving aniline in an organic solvent to form an oil phase suspension.

[0055] Specifically, aniline is purified by distillation under reduced pressure, such as figure 1 As shown, then, the purified aniline was dissolved in carbon tetrachloride organic solvent, the concentration of aniline was 0.5mol / L, stirred for 1h, and the stirring speed was 50rpm, to obtain an oil phase suspension with uniform dispersion of aniline.

[0056] Step 2, performing surface modification with a silane coupling agent and nitration surface modification on the cobalt powder to obtain a modified cobalt powder whose surface is rich in amino groups.

[0057] The specific method of modification is:

[0058] Step a. Prepare 50mL mixed solution according to the volume fraction of ethanol: water = 9:1, add 2g of cobalt powder into the solu...

Embodiment 3

[0069] This example provides a method for preparing a self-assembled porous polyaniline / cobalt core-shell spherical structure absorbing material:

[0070] Step 1, dissolving aniline in an organic solvent to form an oil phase suspension.

[0071] Specifically, aniline is purified by distillation under reduced pressure, such as figure 1 As shown, then, the purified aniline was dissolved in carbon tetrachloride organic solvent, the concentration of aniline was 1mol / L, stirred for 1h, and the stirring speed was 50rpm, to obtain an oil phase suspension with uniform dispersion of aniline.

[0072] Step 2, performing surface modification with a silane coupling agent and nitration surface modification on the cobalt powder to obtain a modified cobalt powder whose surface is rich in amino groups.

[0073] The specific method of modification is:

[0074] Step a. Prepare 50mL mixed solution according to the volume fraction of ethanol: water = 9:1, add 2g of cobalt powder into the soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com