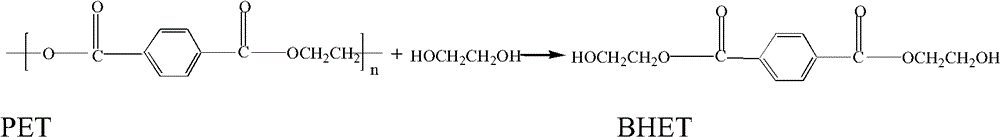

Method for catalytically alcoholizing polyethylene terephthalate

A technology of polyethylene terephthalate and polyethylene terephthalate, which is applied in the field of urea-catalyzed alcoholysis of polyethylene terephthalate, which can solve the problem of difficult separation of catalyst and product and deterioration of plastic performance. Bad question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

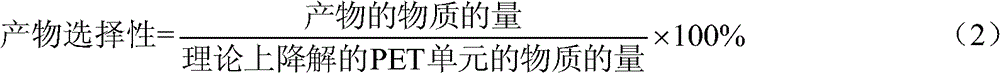

Embodiment 1

[0021] Implementation method: Add 5.0g PET mineral water bottle flakes, 20.0g ethylene glycol and 0.25g urea (CO(NH) 2 ). The reaction temperature was controlled at 180° C. under normal pressure, condensed and refluxed for 2.5 hours, and then cooled to room temperature. Under these conditions, the degradation rate of PET polyester is 73.2%, the selectivity of monomer ethylene terephthalate (BHET) is 74.4%, and the mass percentage of monomer in the product is 90.1%.

Embodiment 2

[0023] Other conditions are with embodiment 1, and the catalyst that adds is 0.5g CO (NH) 2 . Under these conditions, the degradation rate of PET polyester is 100%, the selectivity of BHET is 70.0%, and the mass percentage of monomer in the product is 86.6%.

Embodiment 3

[0025] Other conditions are the same as embodiment 1, and the catalyst that adds is 1.0g CO (NH) 2 . Under these conditions, the degradation rate of PET polyester is 100%, the selectivity of BHET is 72.1%, and the mass percentage of monomer in the product is 90.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com