Preparation method and application of cell-loading three-dimensional support

A three-dimensional scaffold and cell technology, which is applied in the field of cell printing and biomaterials, can solve the problems of cell damage, large shear stress, and susceptibility to environmental influences, and achieve the effects of reducing damage, easy operation, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

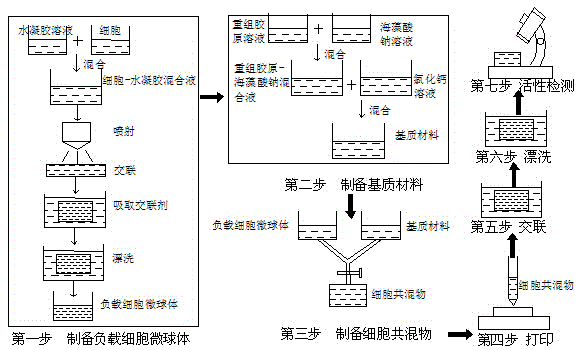

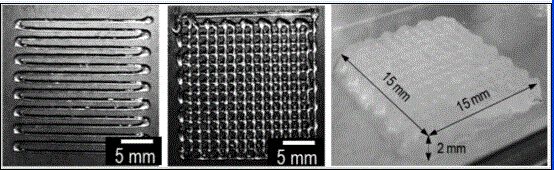

[0034] A method for preparing a cell-loaded three-dimensional scaffold based on cell printing output technology, comprising the following steps:

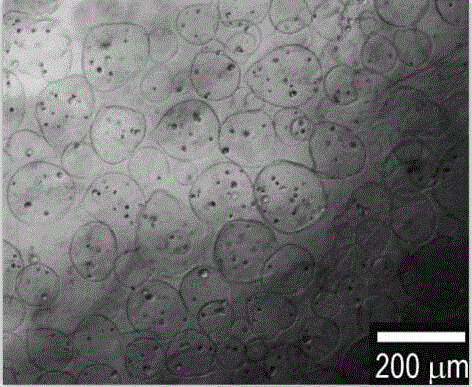

[0035] The first step is to prepare cell-loaded microspheres, mix chondrocytes with 1 wt % sodium alginate aqueous solution sterilized by high temperature intermittently, and the concentration of chondrocytes in the mixture is 2.2×10 5 / mL, according to the injection conditions of pressure 120 kPa and nozzle diameter 730 μm, the mixed solution was sprayed to a concentration of 2 wt% crosslinking agent CaCl 2 solution, let stand for 10min, remove CaCl2 solution, rinsed 3 times with PBS solution, and 3 times with DMEN cell culture solution to obtain cell-loaded microspheres for later use.

[0036] In the second step, the matrix material was prepared, and a recombinant collagen solution with a concentration of 7wt% and a sodium alginate solution with a concentration of 7wt% were respectively prepared, mixed at a mass ratio of 1:1, and ...

Embodiment 2

[0043] A method for preparing a cell-loaded three-dimensional scaffold based on cell printing output technology, comprising the following steps:

[0044] The first step is to prepare cell-loaded microspheres, mix bone marrow mesenchymal stem cells with 2.5 wt % sodium alginate aqueous solution which is intermittently sterilized at high temperature, and the concentration of chondrocytes in the mixture is 5×10 5 / mL, according to the injection conditions of pressure 150 kPa and nozzle diameter 500 μm, the mixed solution was sprayed to a concentration of 5 wt% crosslinking agent CaCl 2 solution, let stand for 10 min, remove CaCl 2 solution, rinsed 3 times with PBS solution, and 3 times with DMEN cell culture solution to obtain cell-loaded microspheres for later use.

[0045] The second step is to prepare the matrix material, respectively prepare a recombinant collagen solution with a concentration of 3 wt% and a sodium alginate solution with a concentration of 5 wt%, mix them at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com