Printing device for carton production

A printing equipment and carton technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of inability to dry cardboard printing, inability to absorb and purify odors, no heating chamber and air outlet, etc., to ensure normal printing. process, increase the working area, and facilitate the effect of promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

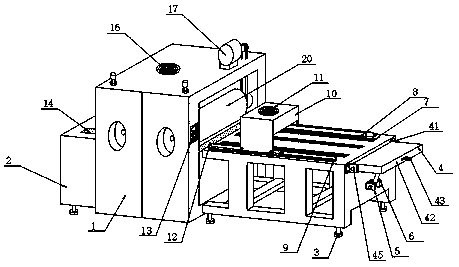

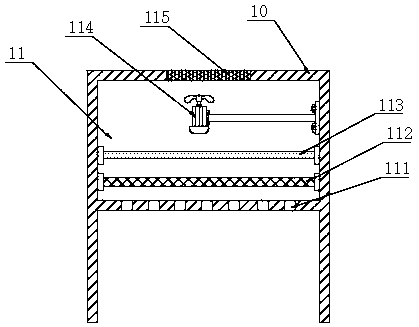

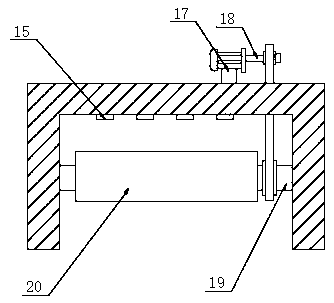

[0026] see Figure 1-6 , in an embodiment of the present invention, a printing device for carton production, including a printing room 1 and a workbench 2, the inside of the printing room 1 is provided with a workbench 2, and the bottom end of the workbench 2 is fixedly installed with a shock-absorbing base 3, which absorbs The bottom end of the shock base 3 is provided with a rubber pad, and the shock-absorbing base 3 and the rubber pad are fixedly connected by an adhesive. The outer wall of one side of the printing room 1 is embedded with a control switch 13, and the inside of the control switch 13 is provided with a MAM-800 A controller, a servo motor 17 is fixedly installed on the upper surface of the printing chamber 1, a main shaft 18 is installed on the rear side of the servo motor 17, a driving wheel is arranged outside the main shaft 18, a belt is connected to the outside of the driving wheel, and the inner top of the printing chamber 1 An air outlet 15 is provided, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com