Ink jet printing apparatus and ink jet printing method

An inkjet printing equipment and inkjet technology, applied in the directions of printing, transfer materials, and kerning mechanisms, etc., can solve problems such as image defects, and achieve the effect of uniform ink concentration and good printed images.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings. In the present invention, "idle scan" means a scanning operation of the print head performed without ejecting ink from the print head for printing purposes.

[0046] 1. Basic structure

[0047] 1.1 Overview of Printing System

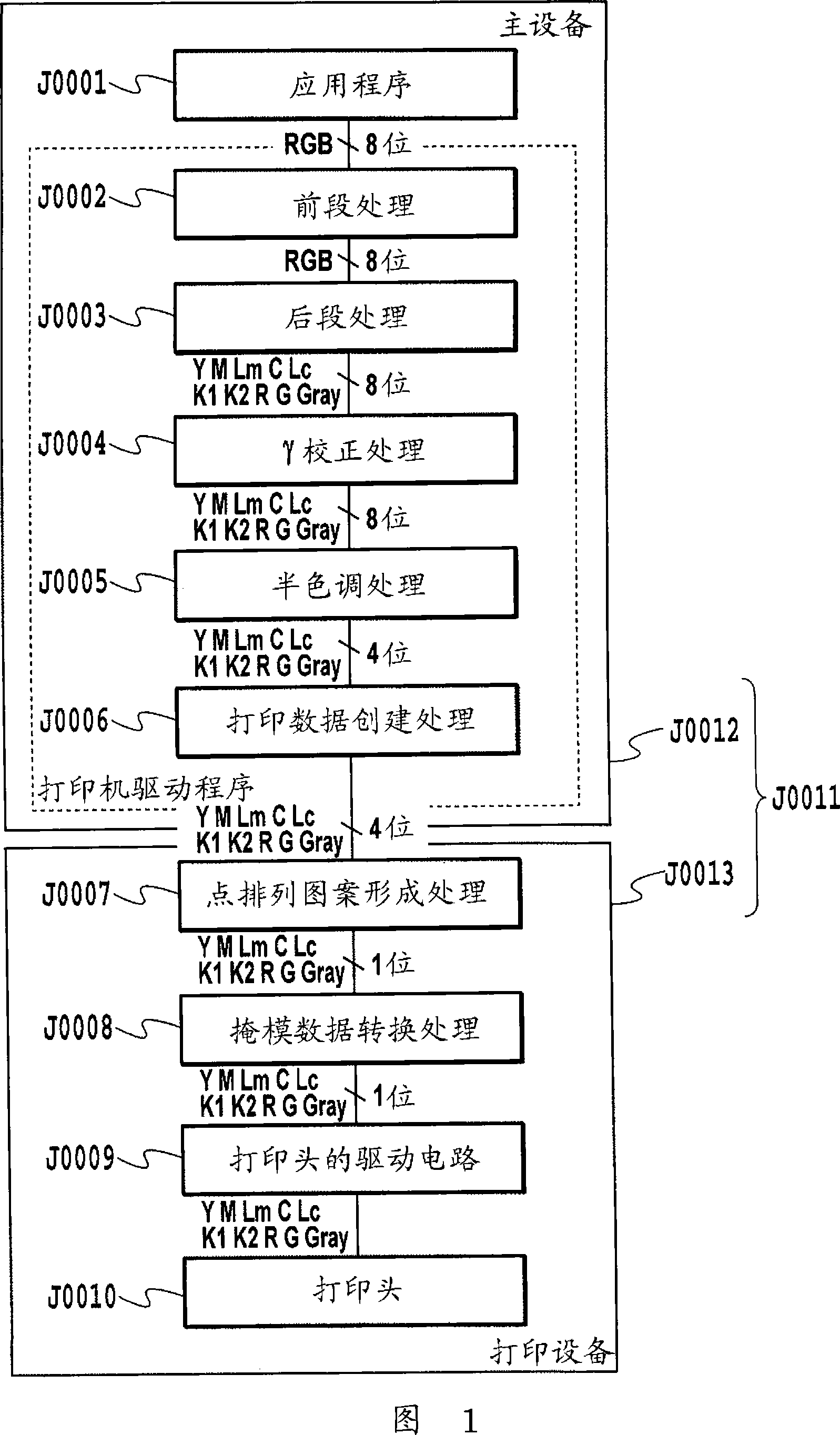

[0048] FIG. 1 is a diagram for explaining the flow of processing image data in a printing system employing an embodiment of the present invention. The printing system J0011 includes a host device J0012 that generates image data representing an image to be printed, and sets a user interface (UI) for generating image data and the like. In addition, the printing system J0011 includes a printing device J0013 for printing an image on a printing medium based on image data generated by the host device J0012.

[0049] Printing device J0013 uses cyan (C), light cyan (Lc), magenta (M), light magenta (Lm), yellow (Y), red (R), gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com