Intermittent rotary printer with cooling units

A technology for printing presses and printing rollers, which is used in printing presses, general parts of printing machinery, printing and other directions, can solve the problems of temperature influence and inaccurate positioning, improve printing quality and printing efficiency, simple structure, and avoid material pulling. stretch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

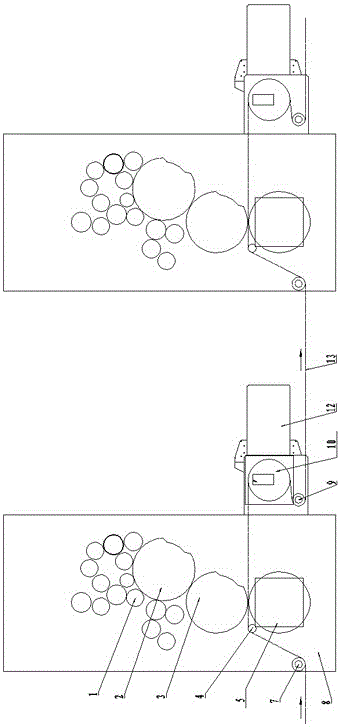

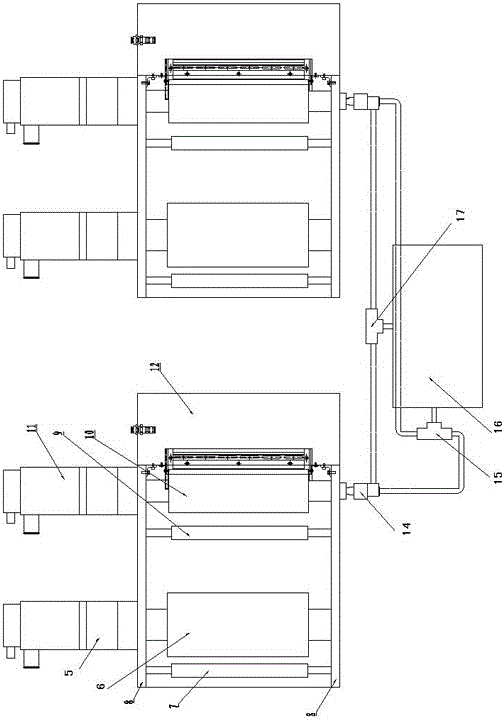

[0020] See attached Figure 1-2 , the printing press disclosed in the present invention is equipped with a cooling unit and is mainly suitable for intermittent rotary printing presses.

[0021] This intermittent rotary printing machine with a cooling unit includes a printing unit, a UV curing unit 12, and a cooling unit. The cooling unit is arranged between the printing unit 1 and the UV curing unit 5 of the printer, and a cooling transmission device is arranged between each printing unit and the UV curing unit.

[0022] The printing unit includes an ink roller 1, a printing roller 2, a rubber roller 3, a support roller 4, an embossing roller servo motor 5, an embossing roller 6, and an embossing roller arranged side by side from top to bottom on the same set of offset printing support plates 8. Roller guide roller 7. The shaft end of the embossing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com