Packaging Box Printing Process to Prevent Excessive Emulsification and Residue of Ink

A packaging box and ink technology, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problems of increasing the amount of anti-emulsifier, increasing the cost of printing manufacturers, and affecting production efficiency, so as to prevent excessive emulsification of ink and avoid unnecessary Waste, the effect of ensuring printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

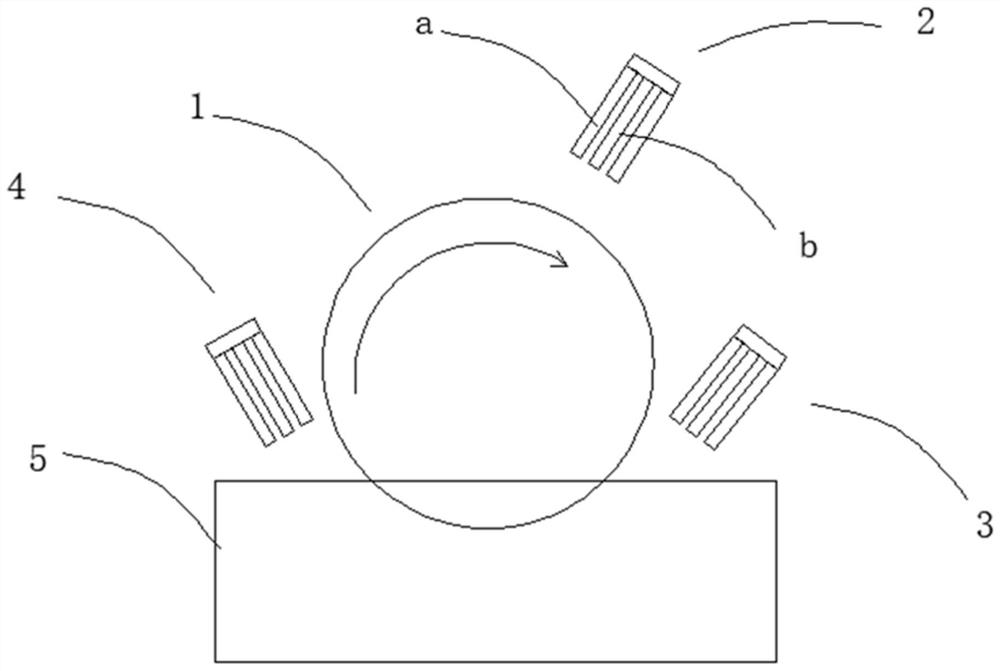

[0036] Such as figure 1 As shown, the direction indicated by the arrow is the rotation direction of the printing plate cylinder 1; a packaging box printing process to prevent excessive ink emulsification and residue generation, after the printing plate cylinder 1 of the printing machine is separated from the paper, use the first air supply device 2 Blow the surface of the printing plate cylinder; when the printing plate cylinder 1 of the printing machine is ink-filled, use the second air supply device 3 to blow the ink surface; after the printing plate cylinder 1 of the printing press is ink-filled Use the third air supply device 4 to blow the surface of the ink at the place where it is separated from the ink;

[0037] The first air supply device 2, the second air supply device 3 and the third air supply device 4 all include an air supply pipe a and a return air pipe b arranged side by side, and the air supply pipe a blows dry cold air, and the return air pipe a The air duct ...

Embodiment 2

[0048] Similar to Embodiment 1, the difference is that the second air supply device is removed.

Embodiment 3

[0050] Similar to Embodiment 1, the difference is that the third air supply device is removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com