Preparation method of high concentration ultrahigh molecular weight polyethylene fiber spinning solution

A polyethylene fiber, ultra-high molecular weight technology, used in spinning solution preparation, single-component polyolefin rayon, flash spinning, etc. problems, to achieve the effect of reducing the number of steps required for extraction, reducing the cost of solvents, and reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

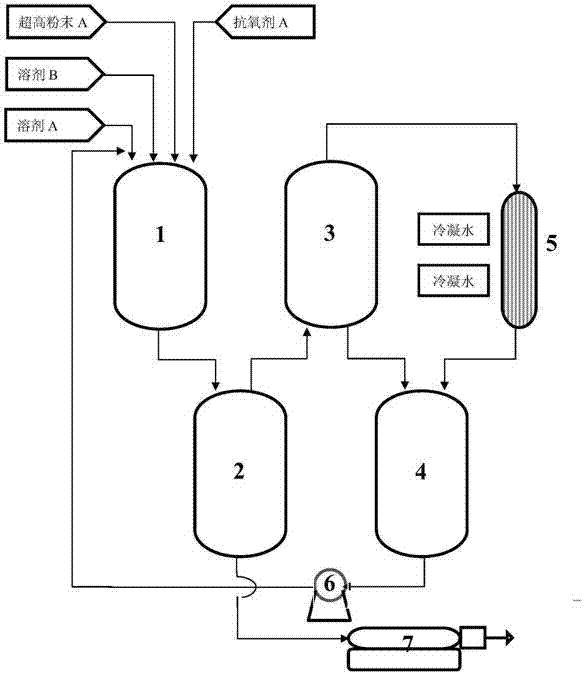

[0033] Such as figure 1 Shown, the preparation method of high concentration ultra-high molecular weight polyethylene fiber spinning solution comprises the following steps:

[0034] Step 1: Take 15 kg of ultra-high molecular weight polyethylene with a weight average molecular weight of 1.5 million, 67 kg of ethyl acetate, 18 kg of kerosene, and 0.45 kg of antioxidant 1010 and put them into the reactor 1. The temperature of the reactor 1 is 110°C-121°C, the pressure is 1MPa, the stirring speed is 200r / min, and the swelling time is 40 minutes.

[0035] Step 2: Relying on the pressure of the reactor 1 itself, by controlling the opening of the discharge valve, the swollen suspension is transported to the flash tank 2 for depressurization and flashing, and the collection tank 4 obtains the suspension after the flashing, and the The suspension is conveyed to the twin-screw extruder 7. Solvent A ethyl acetate with low boiling point is separated in the flash tank 2 and buffered in th...

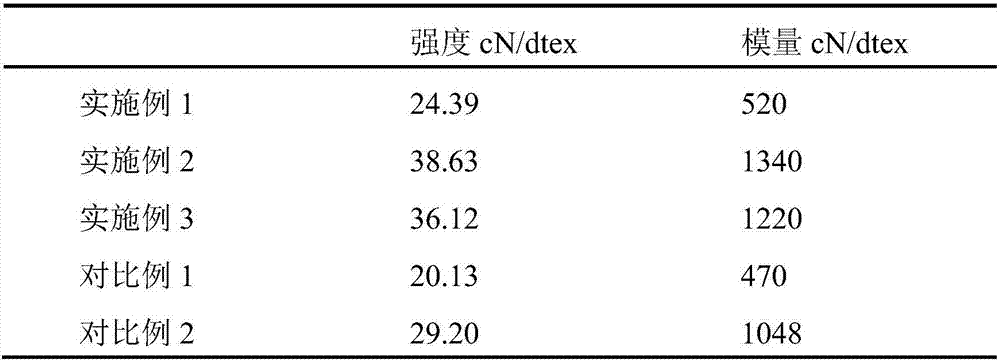

Embodiment 2

[0040]Take 12kg of polyethylene with a viscosity average molecular weight of 8 million, 25kg of n-hexane, 65kg of 15# white oil, and 10100.02kg of antioxidant and put them into the reactor. The temperature of the reaction kettle is 119°C-131°C, the pressure is 1MPa, the stirring speed is 200r / min, and the swelling time is 80 minutes.

[0041] Relying on the pressure of the reactor itself, by controlling the opening of the discharge valve, the swollen suspension is transported to the flash tank for decompression flashing, and the collection tank obtains the flashed suspension, and the suspension is transported to the twin-screw.

[0042] The twin-screw feed temperature is 120°C, the mixing section temperature is 200°C, the discharge temperature is 180°C, and the rotation speed is 60r / min. After the suspension was dissolved by twin-screw mixing extrusion, an ultra-high molecular weight polyethylene spinning solution with a polyethylene mass fraction of 15.6% was obtained.

[00...

Embodiment 3

[0045] Take 15kg of polyethylene with a viscosity average molecular weight of 2 million, 50kg of n-hexane, 40kg of paraffin oil, and 10100.3kg of antioxidant and put them into the reactor. The temperature of the reaction kettle is 115°C-129°C, the pressure is 1MPa, the stirring speed is 200r / min, and the swelling time is 50 minutes.

[0046] Relying on the pressure of the reactor itself, by controlling the opening of the discharge valve, the swollen suspension is transported to the flash tank for decompression flashing, and the collection tank obtains the flashed suspension, and the suspension is transported to the twin-screw.

[0047] The twin-screw feed temperature is 120°C, the mixing section temperature is 190°C, the discharge temperature is 175°C, and the rotation speed is 120r / min. After the suspension was dissolved by twin-screw mixing extrusion, an ultra-high molecular weight polyethylene spinning solution with a polyethylene mass fraction of 27.3% was obtained.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com