High-back-pressure seawater hydraulic frictional wear test bed

A technology of friction and wear test and high back pressure, which is applied in testing wear resistance, testing of mechanical parts, testing of machine/structural parts, etc. Strong corrosion, unbalanced force on the valve plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

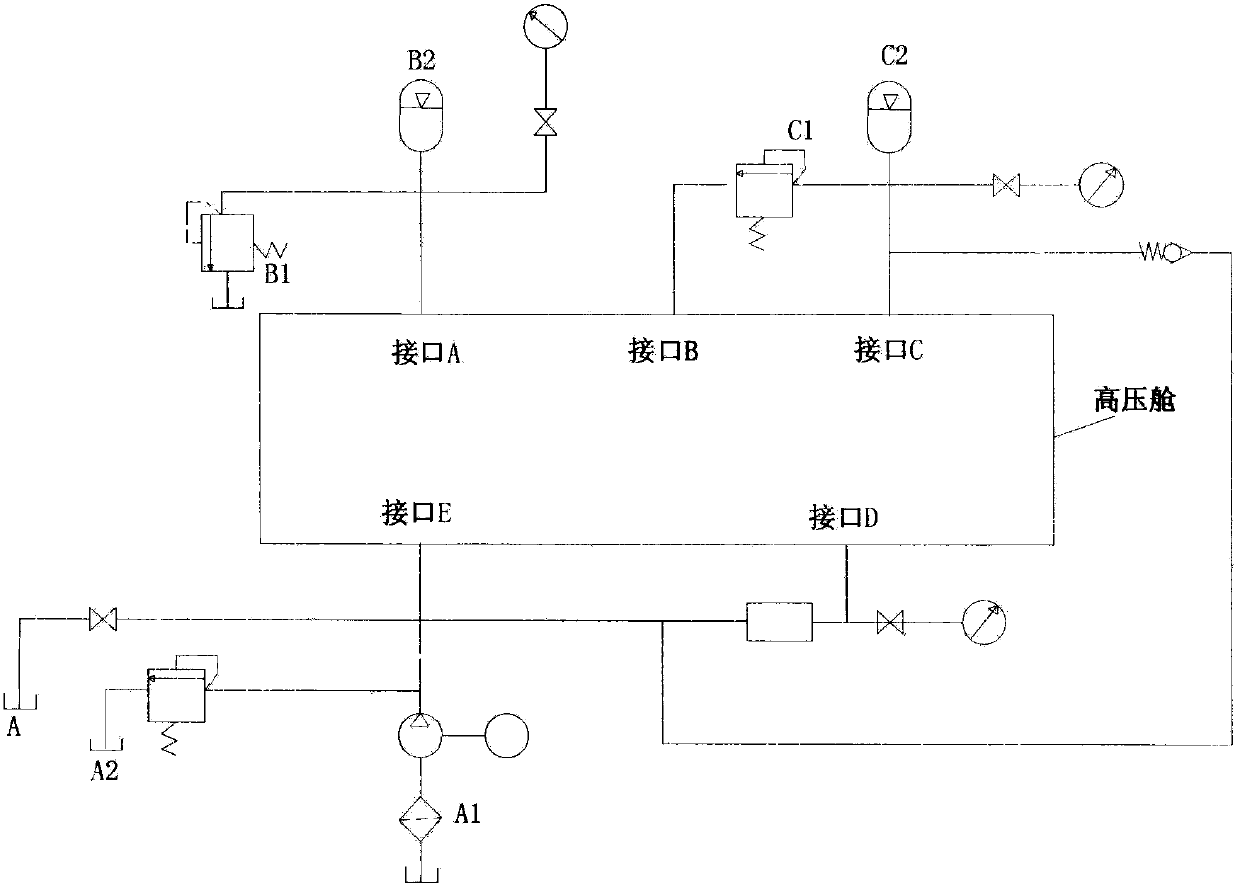

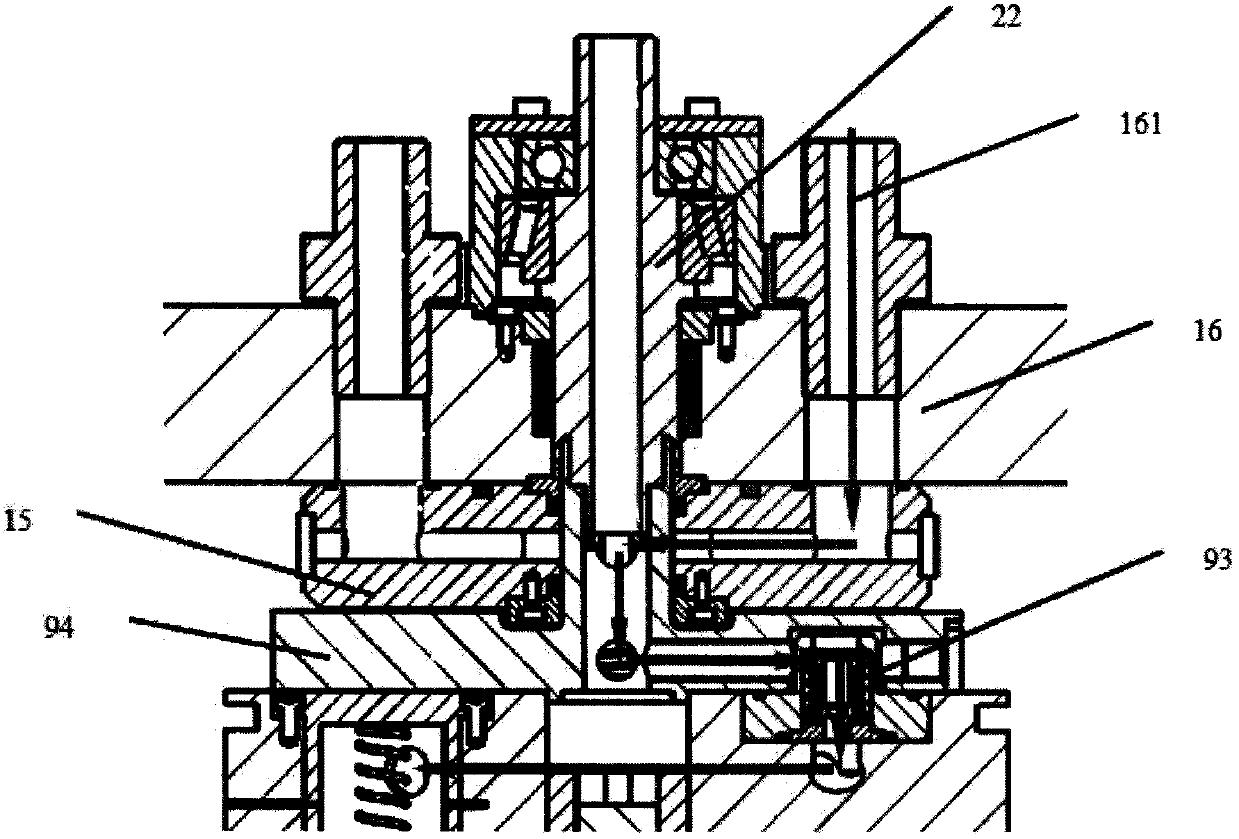

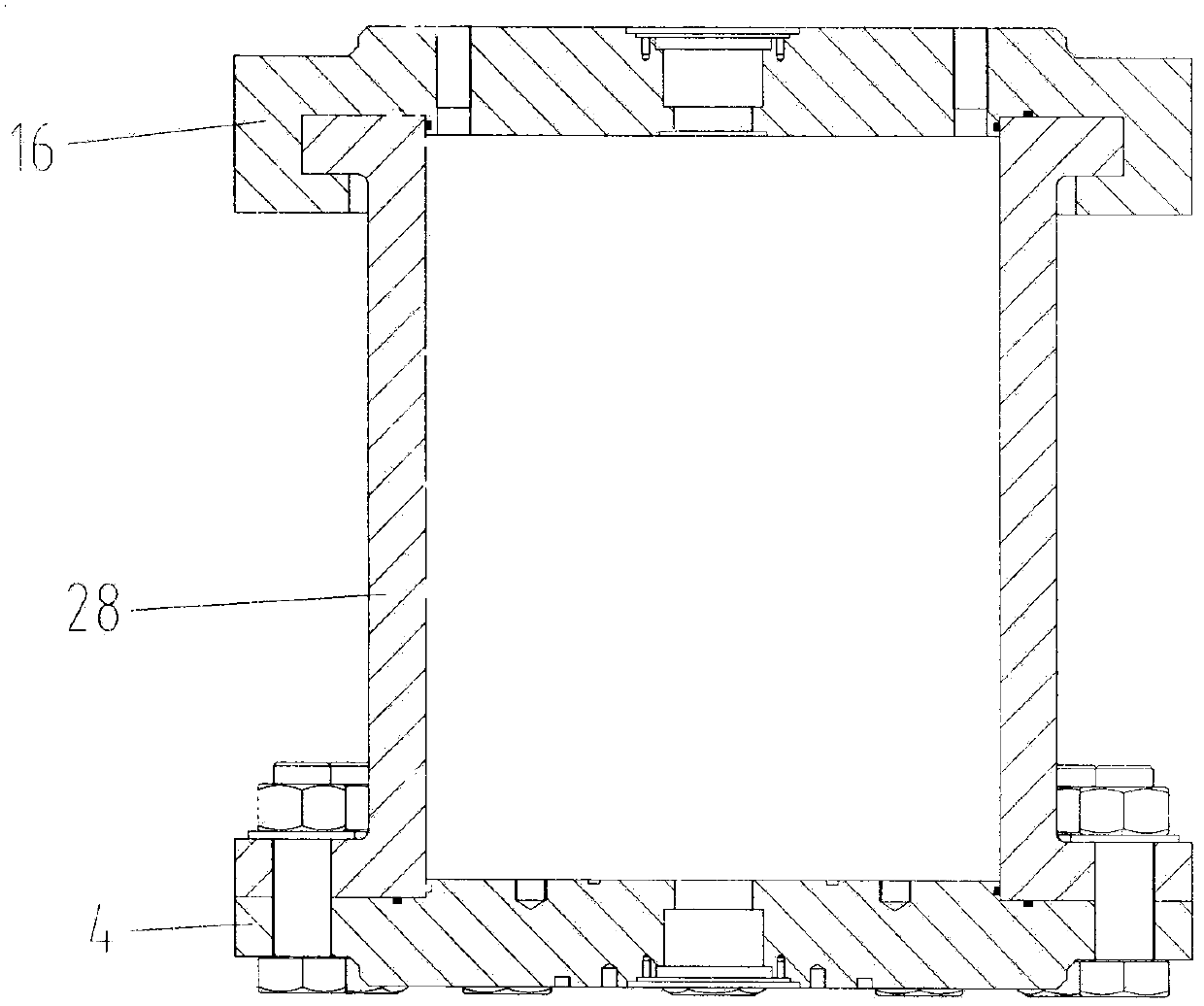

[0033] Example 1, such as figure 1 , figure 2 , Figure 4 As shown, this embodiment discloses a high back pressure seawater hydraulic friction and wear test bench, including a bracket, a hyperbaric cabin is installed on the bracket, a pipe joint 3 is arranged on the hyperbaric cabin, and a high-pressure power source is injected into the hyperbaric cabin through the pipe joint 3 For high-pressure seawater, a swash plate assembly and a plunger cylinder assembly are arranged in the hyperbaric chamber, and one end of the plunger cylinder assembly is fixedly connected to the valve sleeve 94 through the suction valve 93, and the other end is in contact with the swash plate assembly through the sliding shoe 85; The shaft one 1 entering the hyperbaric chamber passes through the swash plate assembly and is fixedly connected with the valve sleeve 94, and the valve sleeve 94 penetrates the distribution sleeve 15 fixed on the hyperbaric chamber and then penetrates the shaft two in the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius of gyration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com