High-voltage transmission conductor tension detection device

A technology of tension detection and high-voltage power transmission, which is applied in tension measurement and other directions, can solve problems such as unstable work, high cost, and difficult processing of detection data, and achieve the effects of convenient operation, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

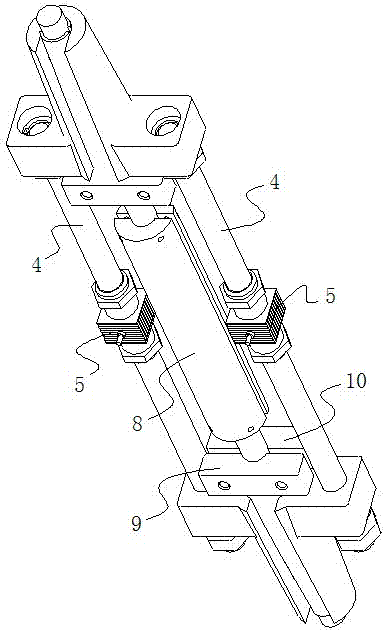

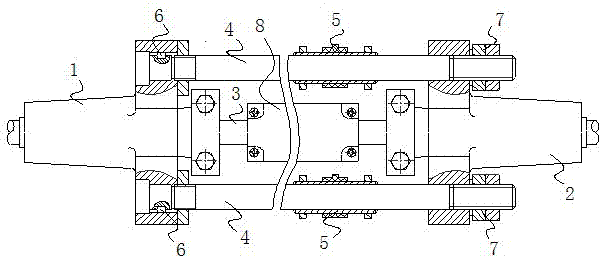

[0015] see figure 1 and figure 2 , the present invention includes an upper wire clamp 10 and a lower wire clamp 9, the upper and lower wire clamps clamp the high-voltage power transmission wire 3 in the wire clamp through washers and bolts, the upper and lower wire clamps are nested in the front wire clamp body 1 and the rear wire clamp body 2, and the wire Both sides of the clip body are provided with mounting holes and keyways for connecting the tie rod 4, which are connected by the key 6 to limit the rotation of the connecting tie rod 4. The connecting rod 4 is provided with threads, and is fixed with the clamp body by a washer and a nut. The other end of the wire is provided with a corresponding wire clamp and wire clamp body, and the other end of the connecting rod is fixed with the wire clamp body through a washer, double nuts, and the power transmission wire in the middle part of the two wire clamp bodies is equipped with a crimping tube 8, Force sensors 5 are install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com