Granary automatically exhausting air regularly

A granary, automatic technology, applied in the field of granaries, can solve the problems of not being able to prevent insects, rodents, mildew, no ventilation, grain mildew, etc., to facilitate air circulation, prevent grain mildew, and store grain conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

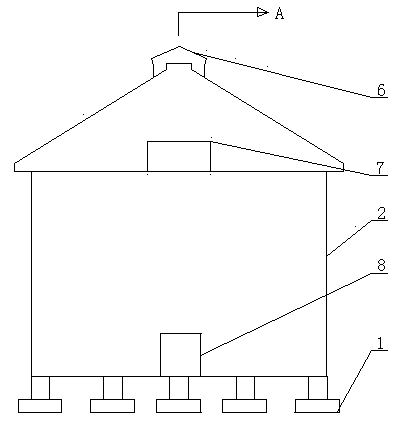

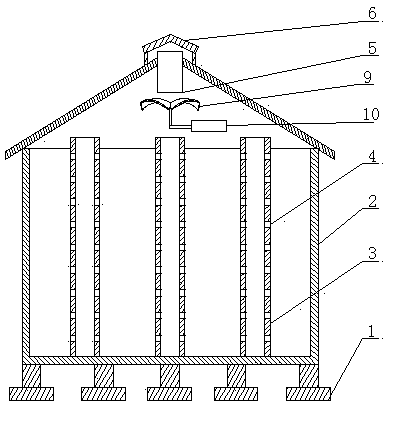

[0015] as attached figure 1 As shown: the timing automatic exhaust granary of the present invention includes a base 1 on which a bin body 2 is installed, and a group of exhaust columns 3 are arranged inside the bin body, and the top of the bin body has a main row Inflator 5, the top of the main exhaust cylinder has an umbrella cap 6, the bottom of the main exhaust cylinder is connected to an exhaust fan 9, and the exhaust fan is connected to a timing controller 10. The upper part has a grain inlet 7, and the bottom of the warehouse body has a grain discharge port 8.

Embodiment 2

[0017] In the timing automatic exhaust granary, there is a set of ventilation holes 4 on the exhaust column, and the ventilation holes are distributed on the warehouse body.

Embodiment 3

[0019] In the timing automatic exhaust granary, the ventilation hole density arrangement of the storage body is dense at the bottom and gradually sparse upwards, the bottom of the storage body has supporting feet, and the storage bottom also has ventilation holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com