Paper feeding assembly used for printer

A technology for printing presses and paper feeding rollers, applied in the field of paper feeding devices, can solve the problems of lack of detection devices, paper adsorption, paper overlapping, etc., and achieve the effects of ensuring normal transportation, avoiding separation, and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

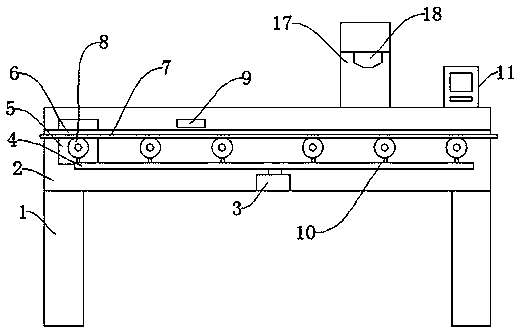

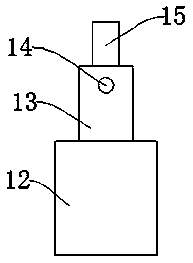

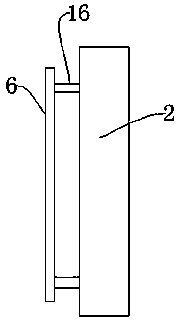

[0023] The present invention will be further described below in conjunction with accompanying drawing:

[0024] Such as Figure 1-Figure 3 As shown, a paper feeding device for a printing machine includes a foot 1, a workbench 2 and an electrostatic generator 3, a workbench 2 is arranged on the upper side of the foot 1, and an electrostatic generator is arranged on the side of the workbench 2 away from the foot 1 3. The upper side of the electrostatic generator 3 is provided with a support rod 4, and the support rod 4 plays the role of supporting the conductive brush 10. The side of the support rod 4 away from the electrostatic generator 3 is provided with a conductive brush 10, and the lower side of the conductive brush 10 is provided There is a connection seat 12, the connection seat 12 plays the role of connecting the support shaft 13, the upper side of the connection seat 12 is provided with a support shaft 13, and the side of the support shaft 13 away from the connection s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com