Water removing device for cable surface

A cable and cable channel technology, applied in the field of cable surface water removal devices, can solve the problems of substandard rubbing resistance, a large amount of water stains, difficult printing clarity and rubbing resistance, etc., and achieves clear printing and convenient application. , Good water removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

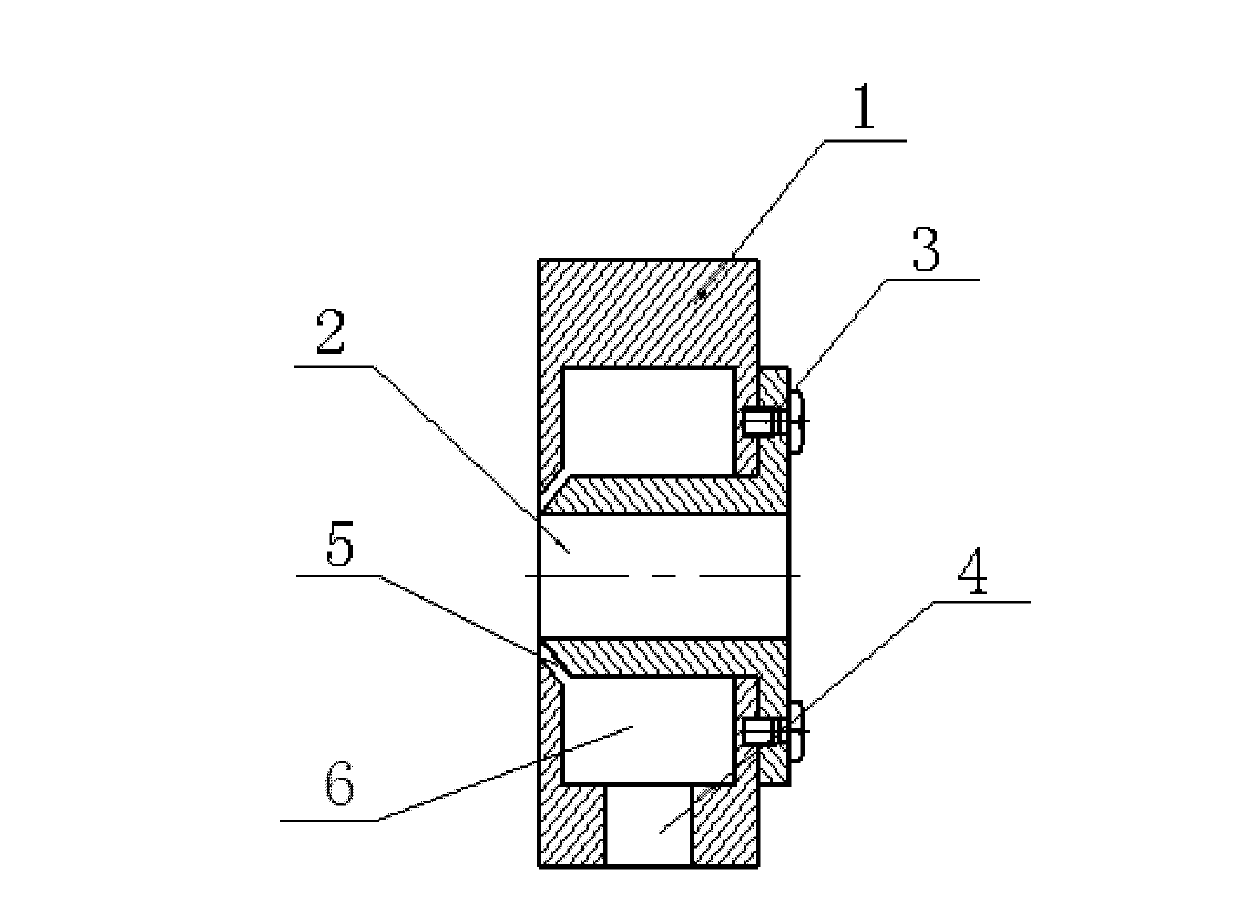

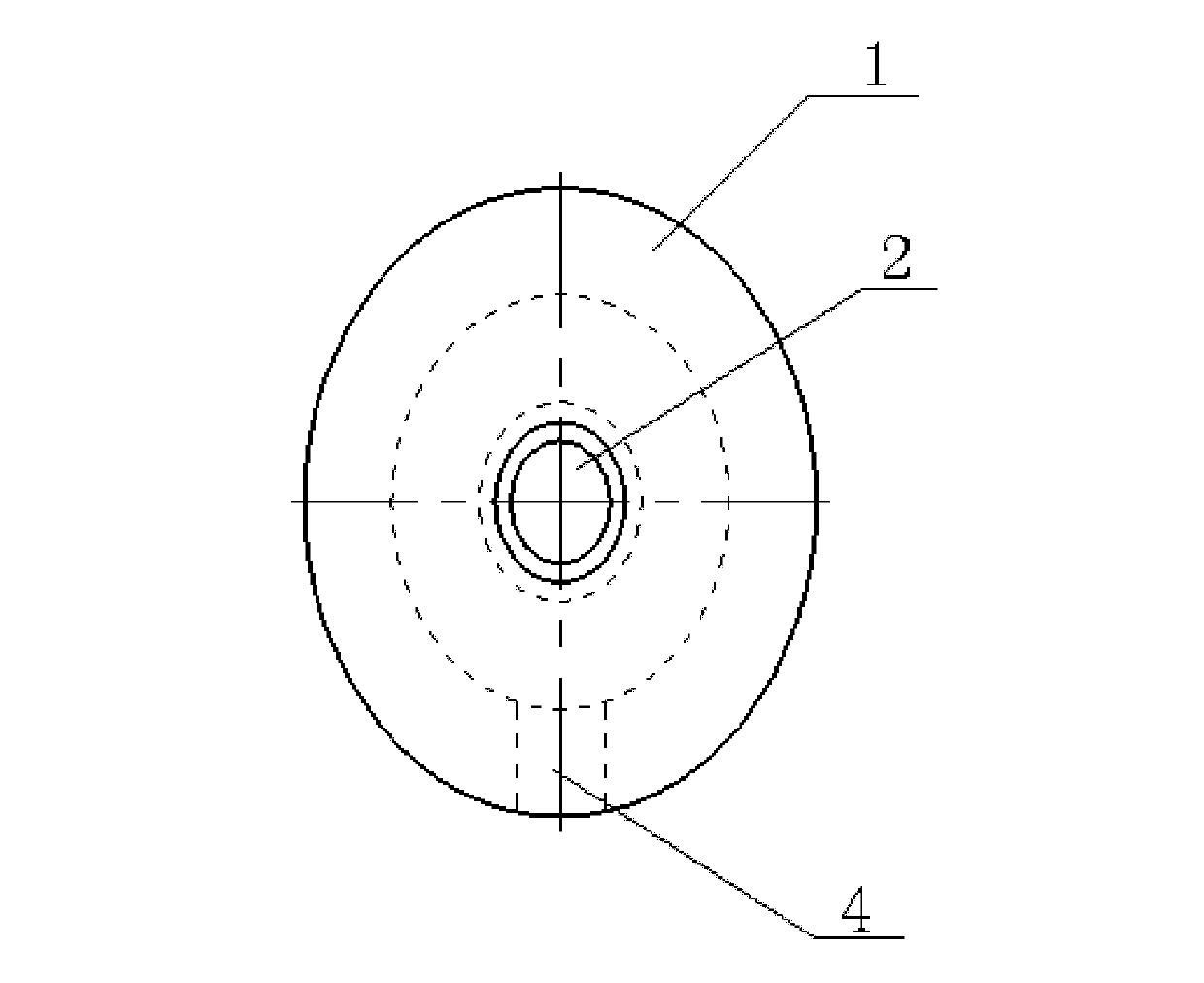

[0016] A cable surface water removal device, the structure is as follows figure 1 , figure 2 As shown, it includes the cable channel 2 and the water eliminator 1, the cable channel 2 is embedded in the water eliminator 1, and an air chamber 6 is provided between the water eliminator 1, and the air flow channel 4 is provided on the water eliminator 1, The airflow passage 4 communicates with the air chamber 6 and the external air pump; the cable is arranged in the cable passage 2, and the air pump feeds the airflow through the airflow passage 4 into the air chamber 6, so that the airflow is uniformly input to the surface of the cable and removes the moisture on the surface of the cable. The water eliminator 1 is in the shape of a hollow cylinder, and the inner diameter of the middle part thereof is greater than the inner diameters of both ends of the water eliminator 1 . The front end of the cable channel 2 is a hollow cylindrical structure. The outer diameter of the hollow cy...

Embodiment 2

[0019] Use the equipment of the present invention to be used for product model specification is ZS-JKLYJ-10kV 1*120mm 2 The cables printed on the cable are license number, manufacturer name, trademark, cable model, specification (including conductor cross-section, number of cores, rated voltage), length in meters and implementation standards.

[0020] Through the dewatering of the device, after the cable is printed by the inkjet printer, it can be found that the printed writing is clear, and the writing basically remains unchanged after wiping, which fully meets the requirements of the relevant national standards.

Embodiment 3

[0022] Use the equipment of the present invention to be used for the product model specification is ZS-JKLYJ-10kV 1*150mm 2 , the product model specification is ZS-JKLYJ-10kV 1*120mm 2 The cables printed on the cable are license number, manufacturer name, trademark, cable model, specification (including conductor cross-section, number of cores, rated voltage), length in meters and implementation standards.

[0023] Through the dewatering of the device, after the cable is printed by the inkjet printer, it can be found that the printed writing is clear, and the writing basically remains unchanged after wiping, which fully meets the requirements of the relevant national standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com