Printer module paper feed-out procedure

a printing module and paper feedout technology, applied in the field of printing modules, can solve the problems of lowering the consumer's will to use the machine, paper waste or printing vague problems, and the application of these advanced machines saves a lot of labor, so as to prevent damage to the internal parts of the printer module, prevent paper waste, and prevent damage to the effect of printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

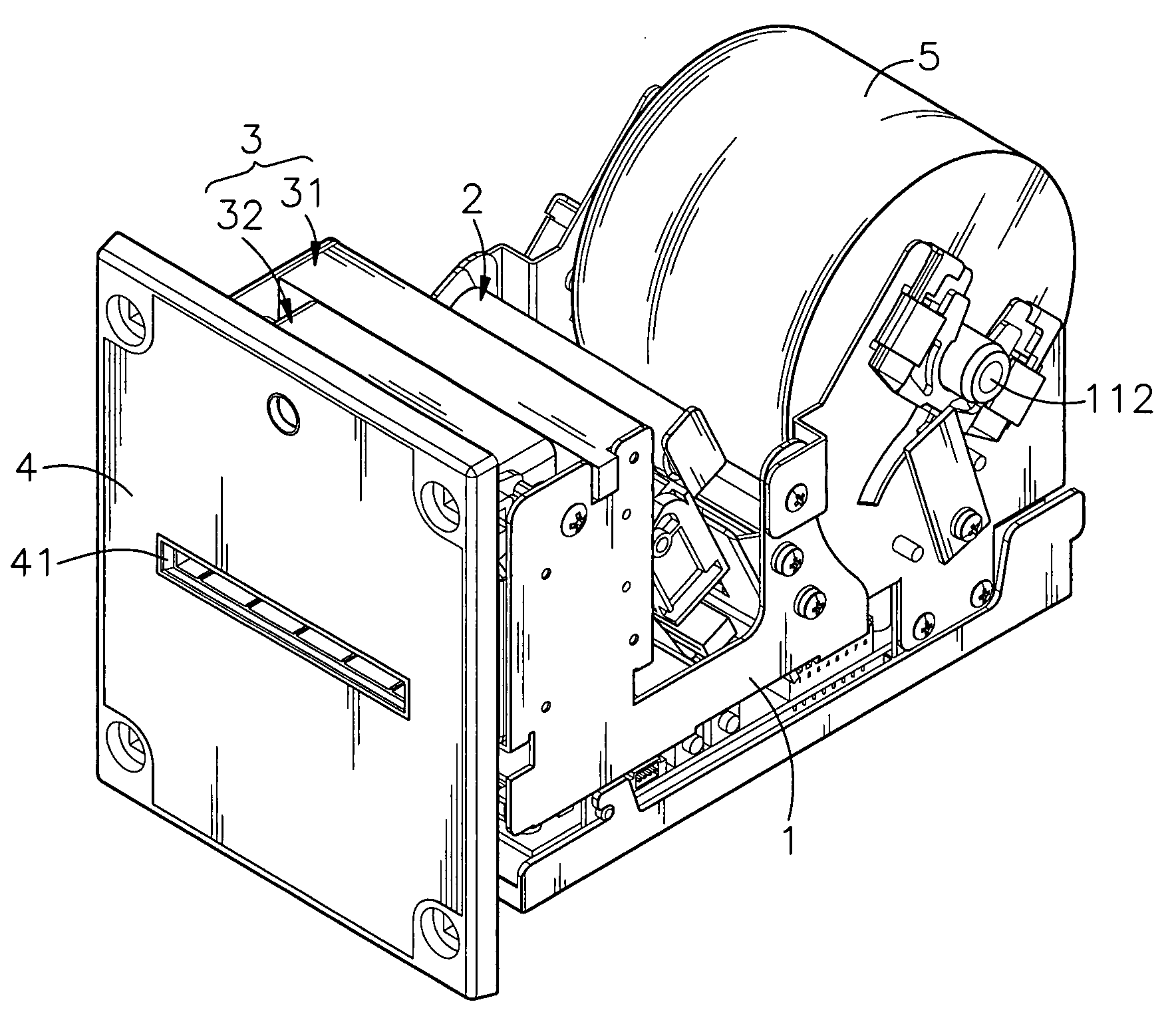

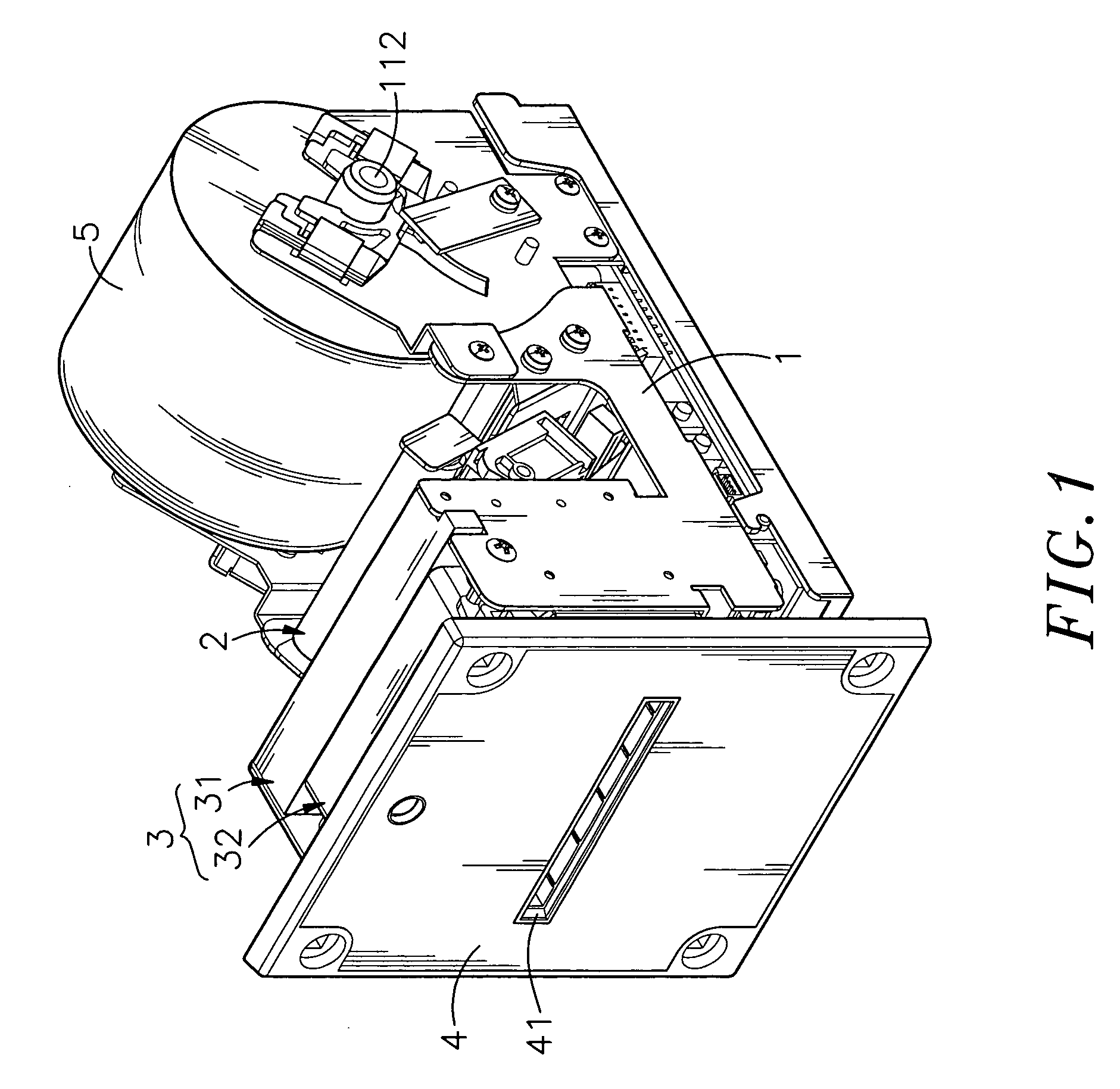

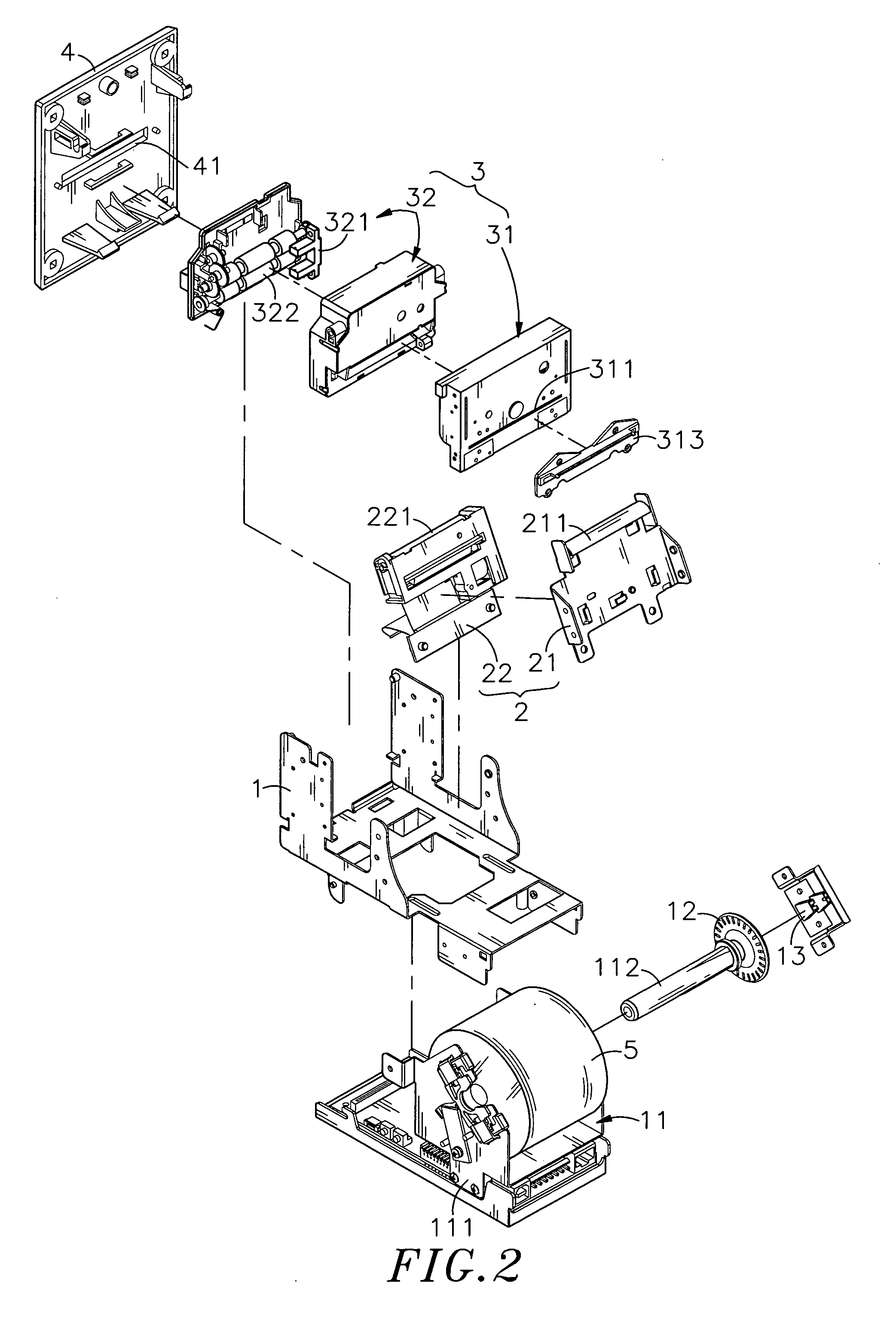

[0019]Referring to FIGS. 1 and 2, a printer module is shown comprising a base frame 1, a printing mechanism 2, a paper feed control module 3 and a face panel 4.

[0020]Referring to FIG. 4 and FIGS. 1 and 2 again, the base frame 1 comprises a pivot holder 11 disposed near one side, namely, the rear side. The pivot holder 11 has two upright supports 111. A pivot shaft 112 is pivotally connected between the two upright supports 111 to support a paper roll 5. An encoder wheel 12 is fixedly fastened to one end of the pivot shaft 112 and disposed outside the pivot holder 11. A sensor 13 is provided adjacent to the encoder wheel 12 for sensing the angle of rotation of the encoder wheel 112.

[0021]The printing mechanism 2 comprises a support base 21 and a printing unit 22. The support base 21 has a paper guide portion 211 for guiding the paper sheet 51 of the paper roll 5 forwards. The printing unit 22 has a sheet-transfer roller set 221 disposed at an elevation below the paper guide portion 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| stretching | aaaaa | aaaaa |

| angle of rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com