Paper clamping device and print using machine

A technology for paper clips and printers, which is applied in the field of paper clip devices and printers, can solve the problems of paper clips cutting through paper, scrapping paper, time-consuming and laborious, etc., and achieving the effect of avoiding scrapping of paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the paper clip device and printer provided by the present invention will be described in detail below with reference to the accompanying drawings.

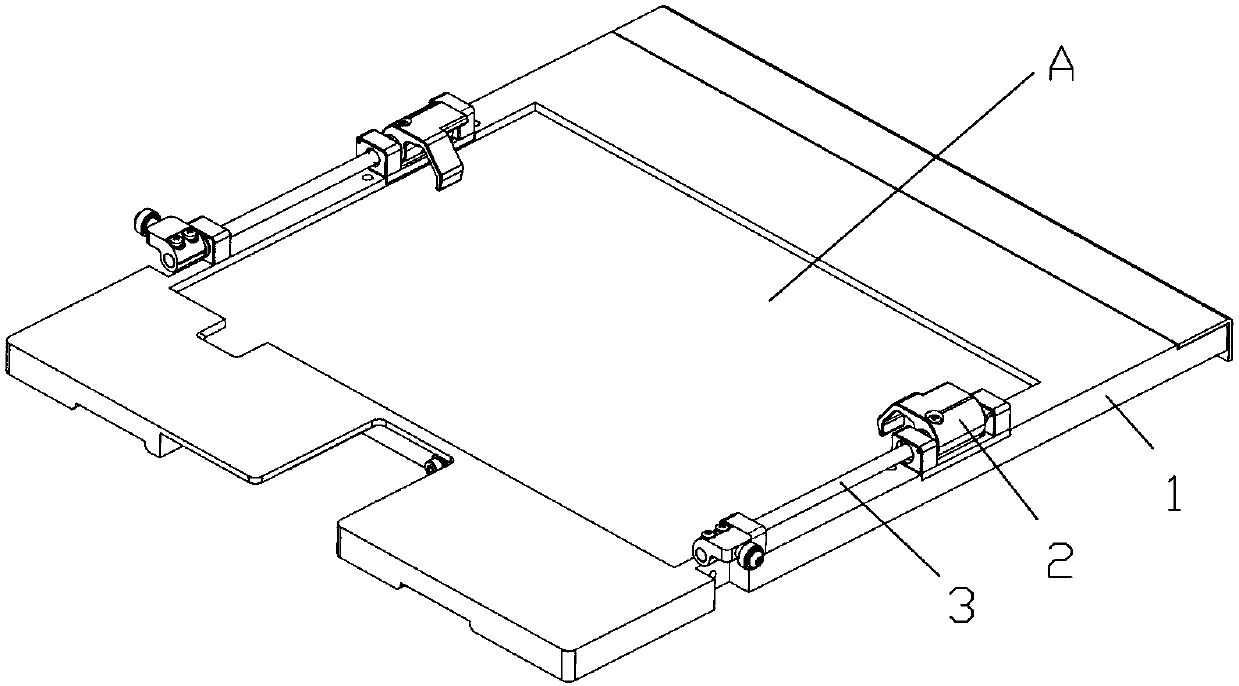

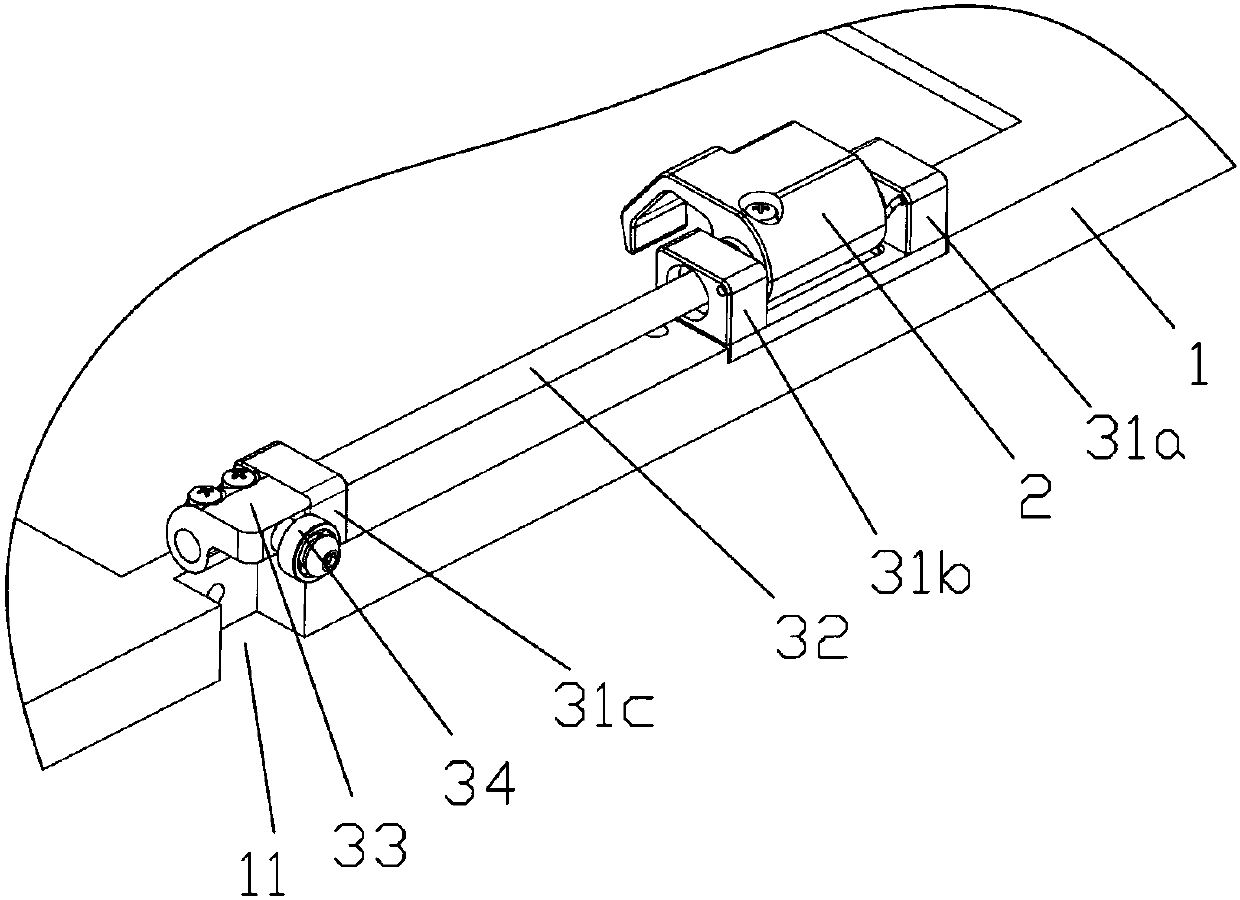

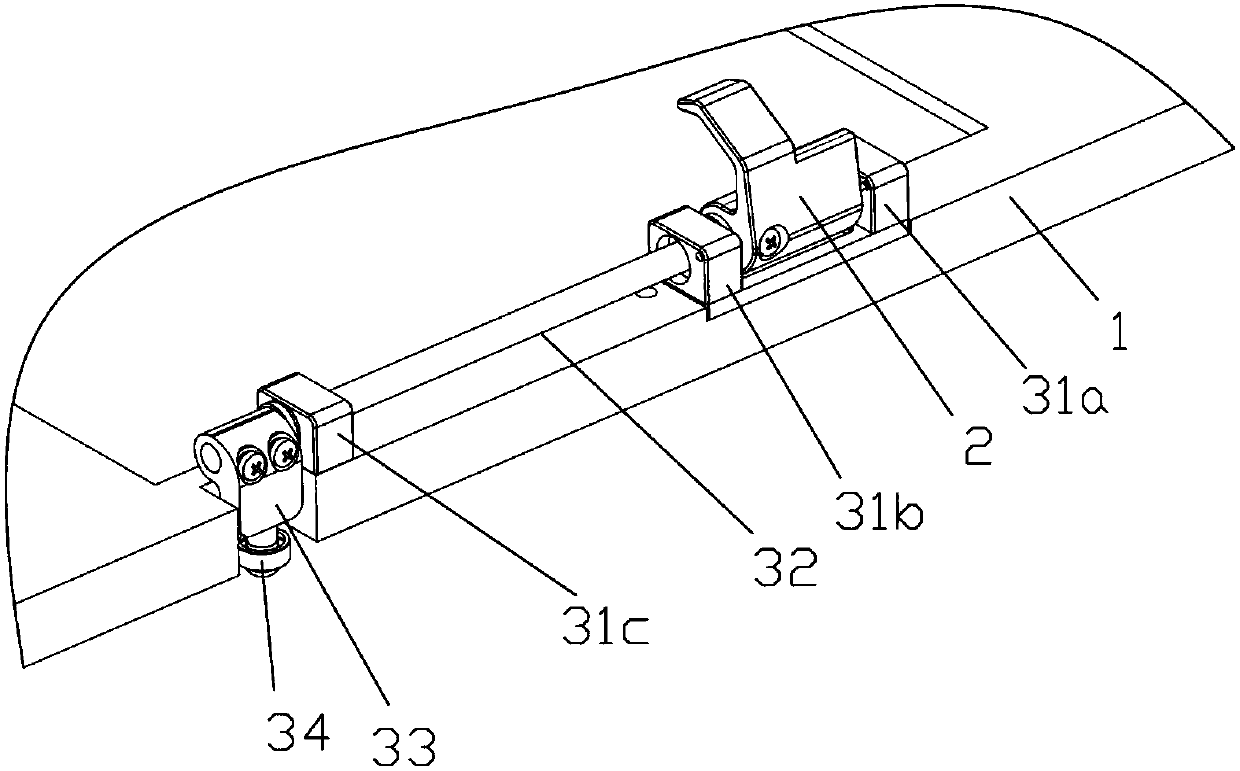

[0038] See figure 1 , The paper clamping device provided by the embodiment of the present invention is used to clamp and fix the paper when the pallet 1 carrying the paper is moved into the printer. The paper clip device includes a clamping assembly which is arranged on the pallet 1. Moreover, there are two sets of clamping components. The two clamping components are on a horizontal plane and symmetrically arranged along the moving direction perpendicular to the pallet 1, and are respectively located on both sides of the bearing surface A of the pallet 1. The so-called bearing surface A refers to the area on the pallet 1 for bearing paper, and the area is consistent with the size and shape of the paper. Of course...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com